Vulcanizing tank

The technology of vulcanization tank and tank body is applied in the field of vulcanization equipment of rubber products, which can solve the problems of poor compactness of the rubber material of the transmission belt, high working temperature of the vulcanized rubber sleeve, shortened service life, etc. The effect of reducing the energy consumption of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

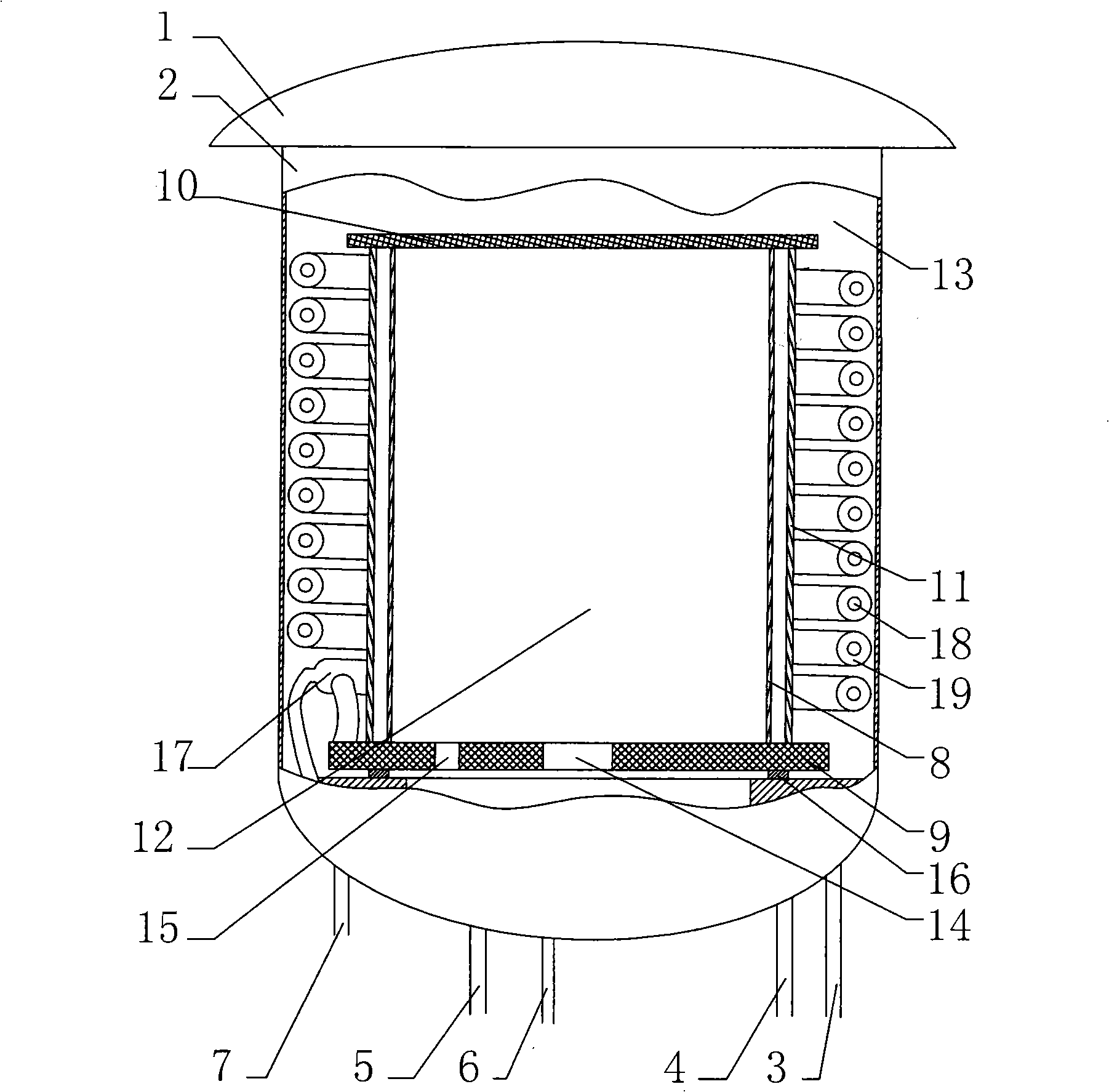

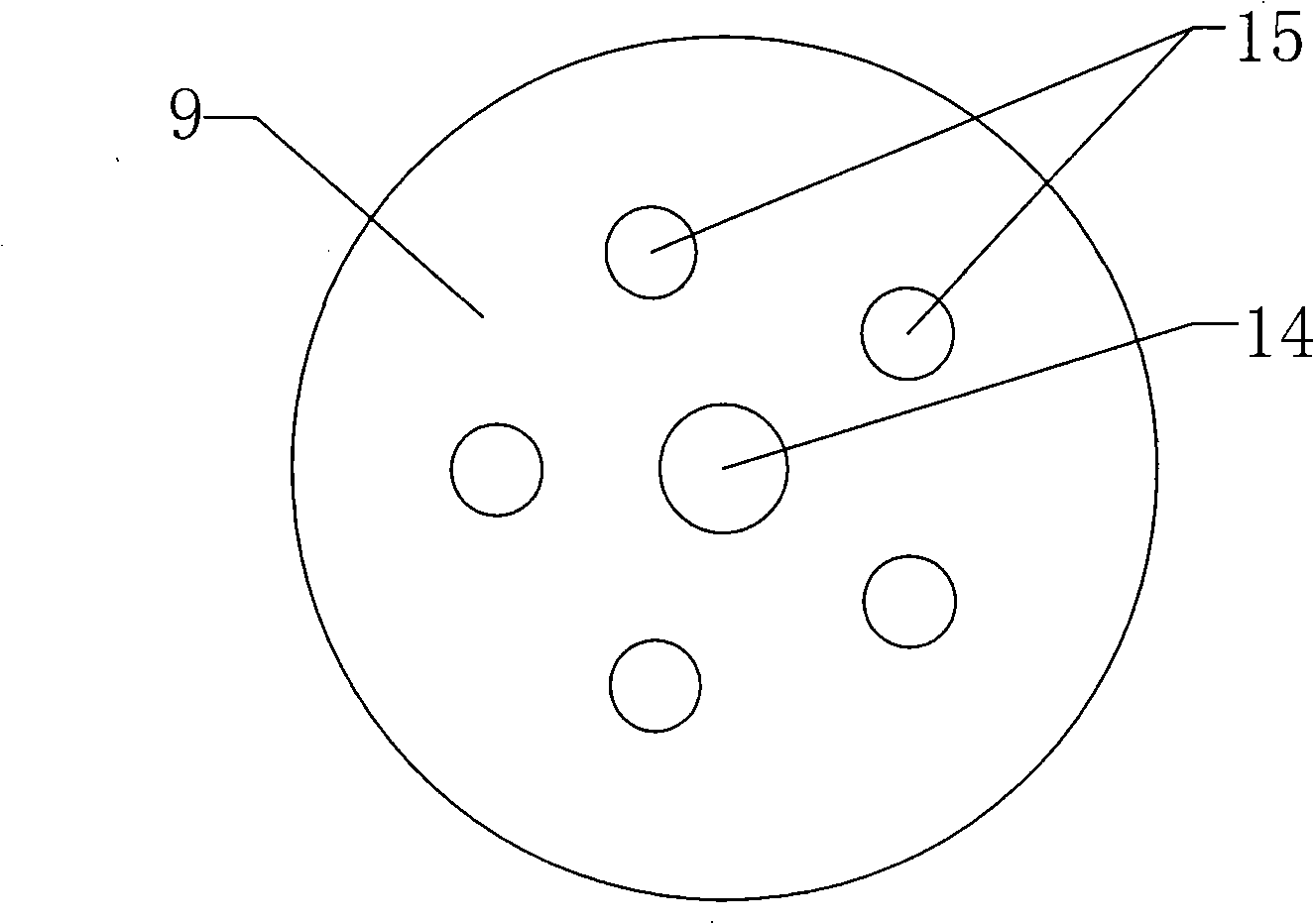

[0011] Such as figure 1 As shown, the autoclave of the present invention includes a tank cover 1 and a tank body 2, and the tank cover 1 is arranged on the top of the tank body 2; an external pressure steam inlet 3, an external pressure steam exhaust port 4, an internal pressure inlet Steam port 5, internal pressure exhaust port 6, air inlet I 7; tank body 2 is provided with a tubular mold 8 that participates in vulcanization, the bottom of the mold 8 is connected to the tank body 2 through a support plate 9, and an upper seal is installed on the top Plate 10, a rubber sleeve 11 at the same height as the mold 8 is installed on the periphery of the mold 8. After installation, the mold 8, the rubber sleeve 11, the upper sealing plate 10, and the support plate 9 divide the inside of the tank body 2 into an inner cavity 12 and an outer cavity 13. The inner cavity 12 belongs to the space surrounded by the mold 8, the upper sealing plate 10, and the support plate 9, which is just in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com