Chain drive mechanism of warp knitting machine

A transmission mechanism and machine chain technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problem that the key, the sprocket and the driving shaft collide with each other, which affects the health of operators, and the installation and maintenance of the sprocket are inconvenient. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

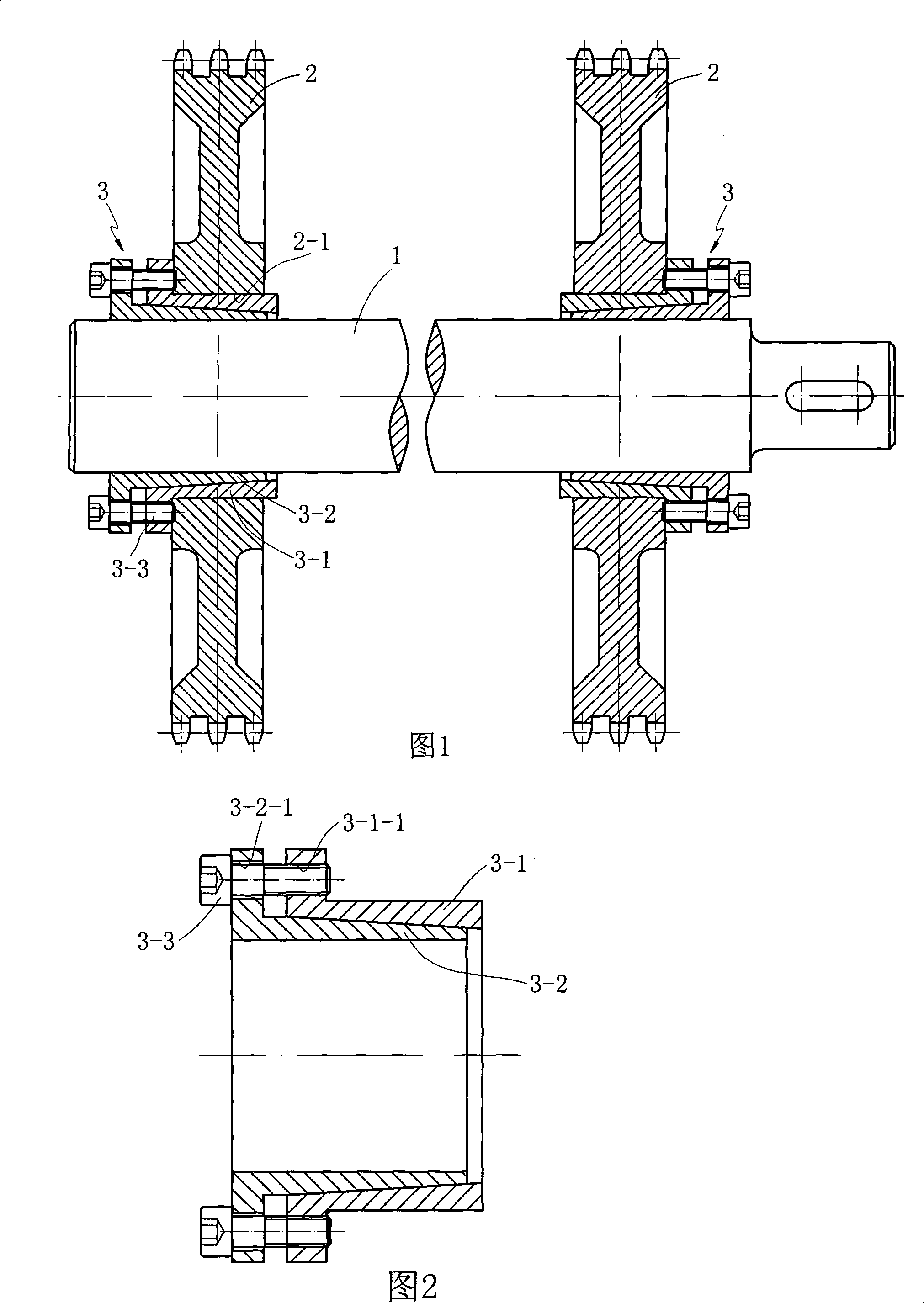

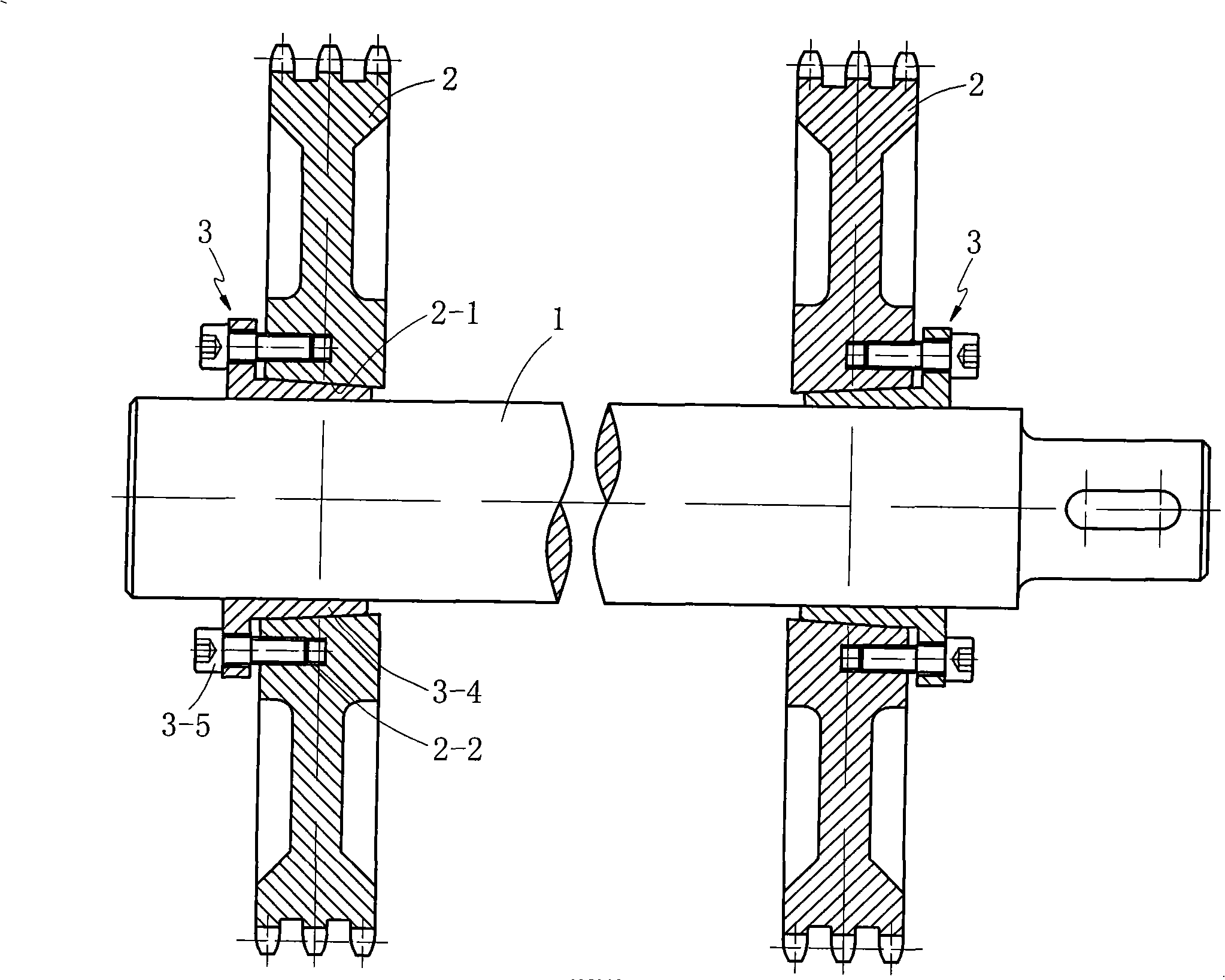

[0013] See Figure 1 to Figure 4 , a warp knitting machine chain transmission mechanism, including a driving device (not shown in the figure), a drive shaft 1 driven by the driving device, a sprocket 2, and a chain (not shown in the figure) meshed with the sprocket 2 for transmission , the chain transmission mechanism also includes an expansion joint 3 for fixedly connecting the sprocket 2 to the drive shaft 1 .

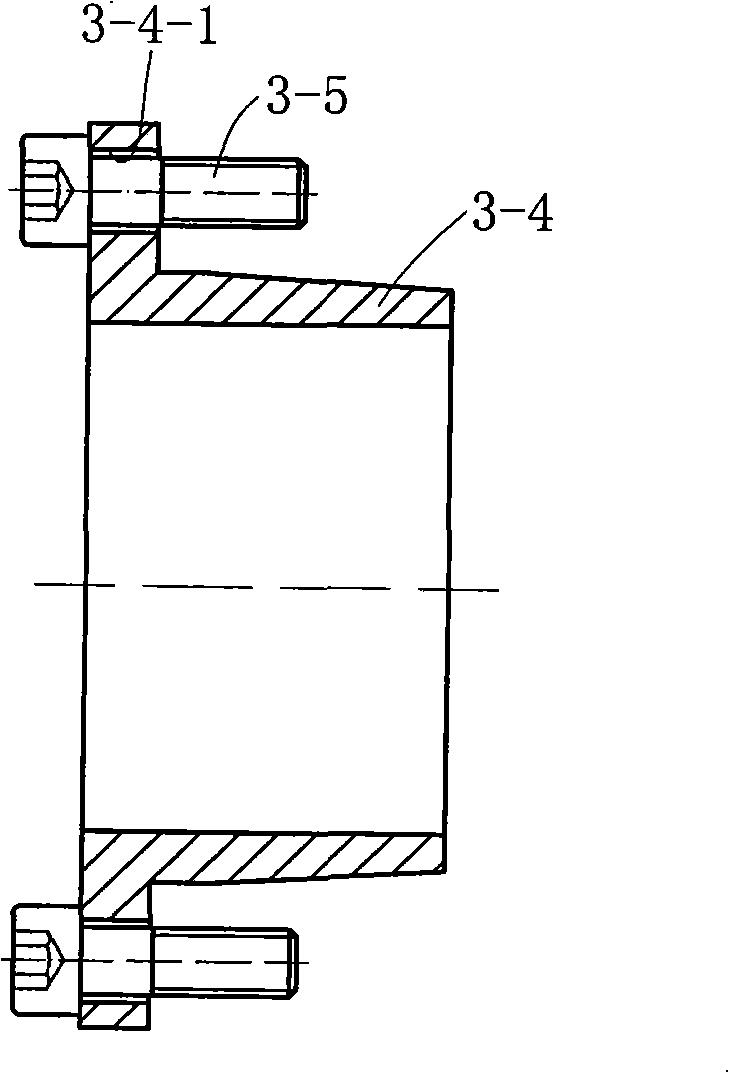

[0014] Referring to Figures 1 and 2, the expansion joint 3 consists of an outer cylinder body 3-1 with an outer flange, an inner cylinder body 3-2 with an outer flange, and an outer cylinder body 3-2 installed between the outer flanges of the inner and outer cylinders. The first bolt 3-3 in between; the inner wall surface of the outer cylinder 3-1 and the outer wall surface of the inner cylinder 3-2 are conical surfaces that cooperate with each other; the outer flanges of the inner and outer cylinders are respectively At least one inner cylinder through hole 3-2-1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com