Projection exposure device and method and device for calibrating illumination light beam dynamic positional error

A lighting beam and dynamic position technology, applied in the field of lithography, can solve the problems of high cost, insignificant effect, and inaccurate displacement correction, and achieve the effect of obvious correction effect, low cost, and elimination of dynamic position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

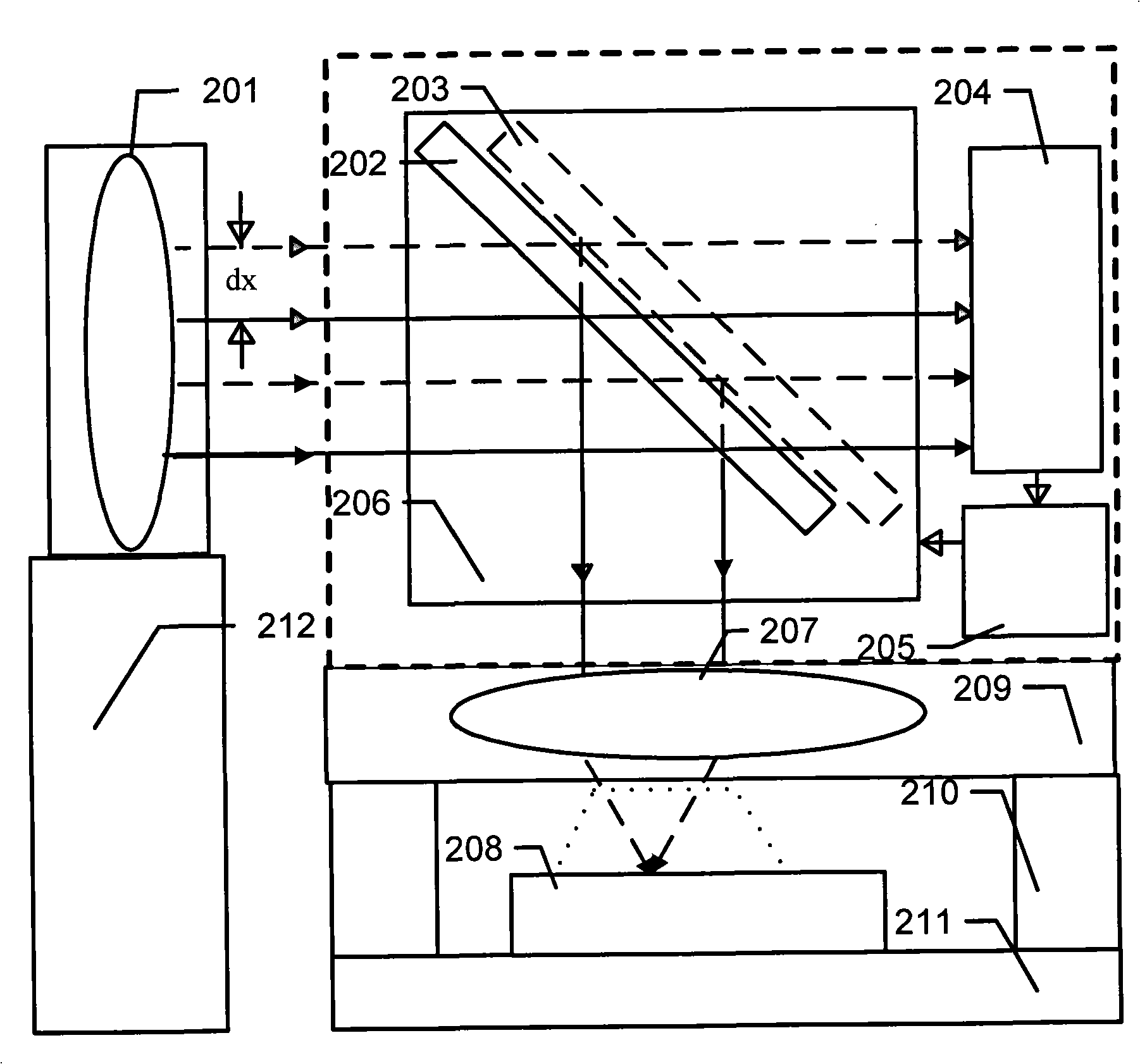

[0028] like figure 2The device for dynamically correcting the dynamic position error of the illumination light beam in this embodiment is shown in the dotted box in the figure, and includes a movable mirror 202, which is a beam splitter with 1% light transmission and 99% light reflection, with an angle of 45 degrees Obliquely placed at the pupil of the lighting mirror group, an image sensor (CCD) or position sensitive sensor (PSD) 204 is used to collect and measure the position of the beam center at the pupil of the lighting mirror group, and a control device 205 can The position of the movable lens 202 is controlled in real time by a motor, and a movable lens frame 206 is used to place and drive the movable lens 202 to translate. It should be noted that, in view of the influence of the dynamic position error in the scanning direction of the illumination beam on the dose performance in scanning exposure is much greater than the impact of the dynamic position error in the non-...

no. 2 example

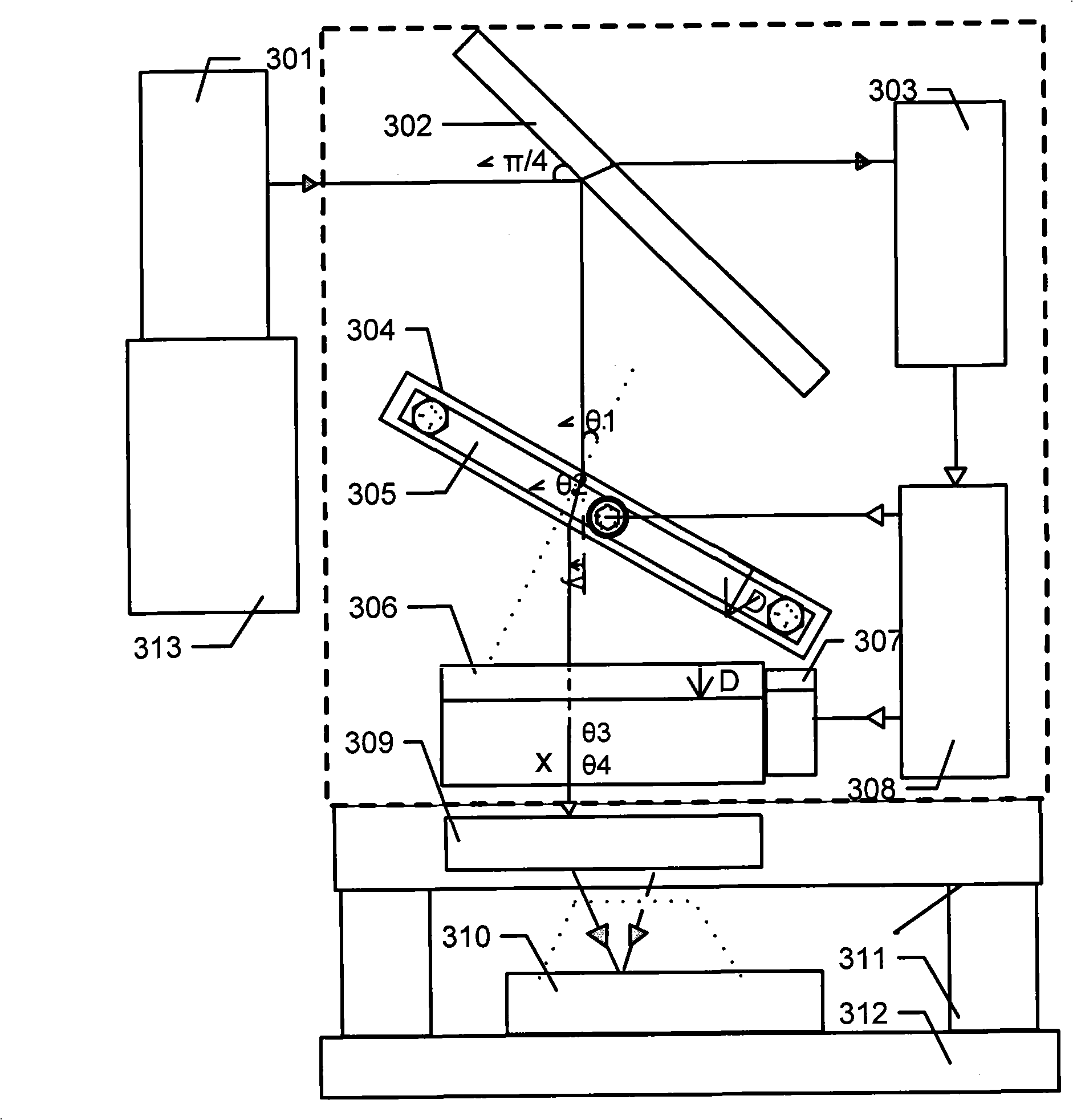

[0034] see image 3 , as shown in the dashed box, the device for dynamically correcting the displacement of the illumination beam relative to the objective lens in this embodiment includes a movable lens group, a pupil position measuring device 303 , and a control device 308 .

[0035] The movable lens group includes a 45-degree oblique 99% reflective and 1% transmissive fixed beamsplitter 302 placed at the pupil of the illuminating mirror group for reflecting and refracting the illuminating beam; The movable refractor 304 whose direction forms an angle of θ1, whose thickness is D, and whose refractive index is n can rotate with the rotating device 305 on the non-scanning direction as the axis, and is used to refract light in the scanning direction and correct the beam position error in the scanning direction, here , the refraction angle is θ2, and the light beam causes a position shift y in the scanning direction; in addition, it also includes a movable refractor 306 with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com