Sowing plough

A technology for sowing furrows and seeders, which is applied in the direction of sowing, plows, shovels, etc., and can solve the problem of reducing the distance between sowing grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

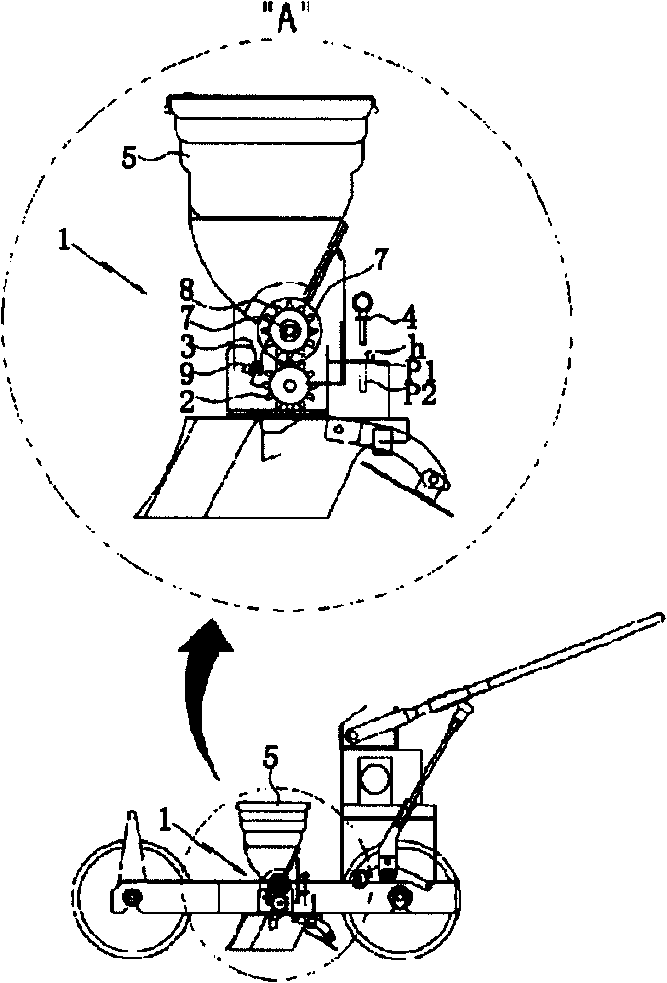

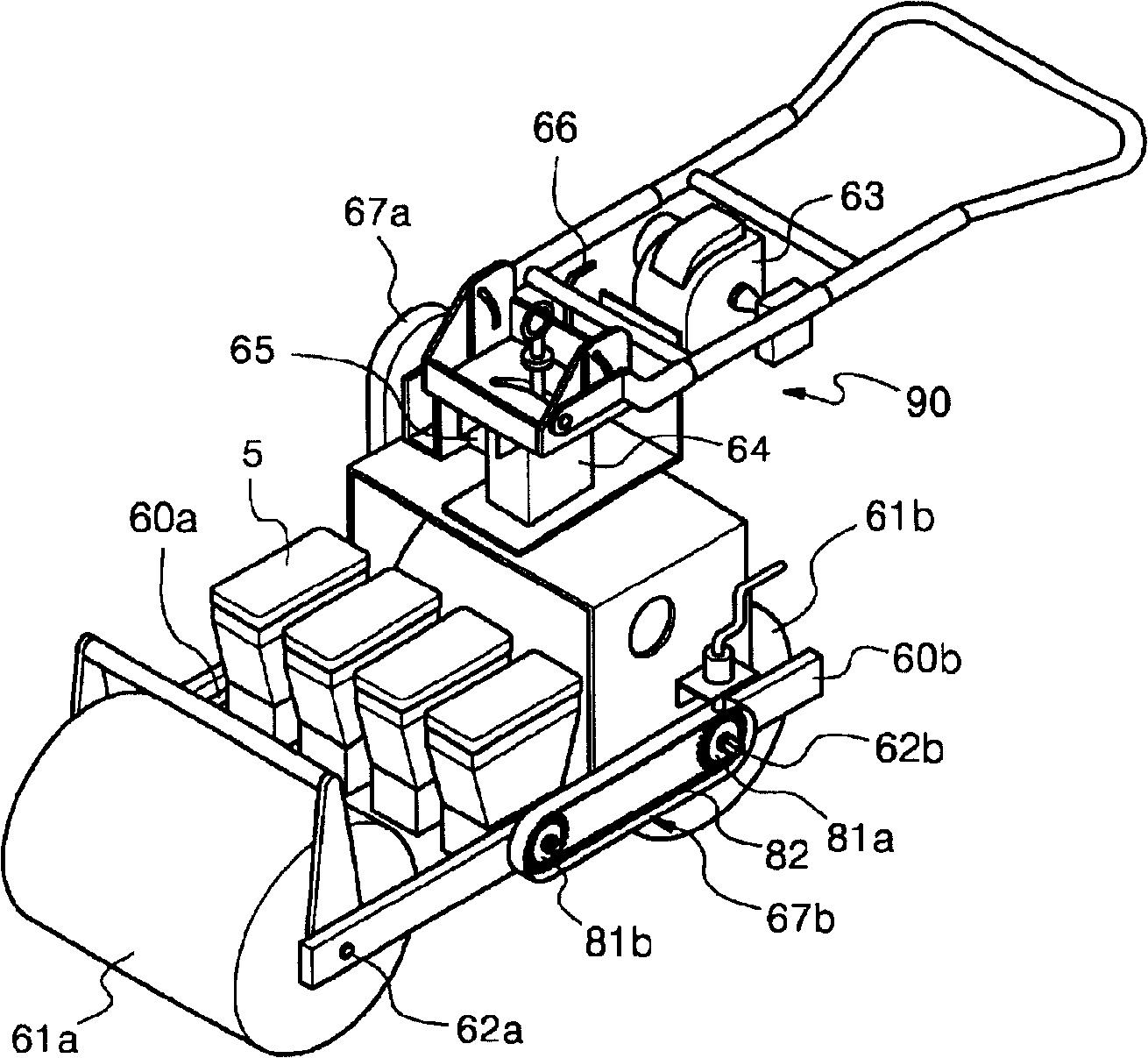

[0038] [35] cf. image 3 , the planter provided with the first roller 61a and the second roller 61b at the front and rear uses the engine 63 (or a driving motor powered by a battery) to generate driving force. Such as Figure 4 As shown, in order to rotate the drive shaft 52 of the hopper mounting unit, the driving force of the engine 63 is transmitted through the engine transmission unit 90 by means of the speed reducer 64, the first clutch 65 for selectively transmitting the rotational driving force and The power transmission device 67a rotates one of the first roller shaft 62a and the second roller shaft 62b, and is connected to the first drive gear 81a and the second roller shaft 62b mounted on the first roller shaft 62a and the second roller shaft 62b, respectively. On one of the two driving gears 81b, the first roller shaft 62a and the second roller shaft 62b are rotated by the first transmission chain 82 connecting them.

[0039] [36] If power transmission can be acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com