Whirlwind type filter cartridge dust wiper

A filter cartridge dust collector and cyclone technology, which is applied in the field of machinery, can solve the problems affecting the stability of the dust collector, inconvenient use process, and difficult to handle dust, and achieves simple operation, convenient cleaning or recycling, and high practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

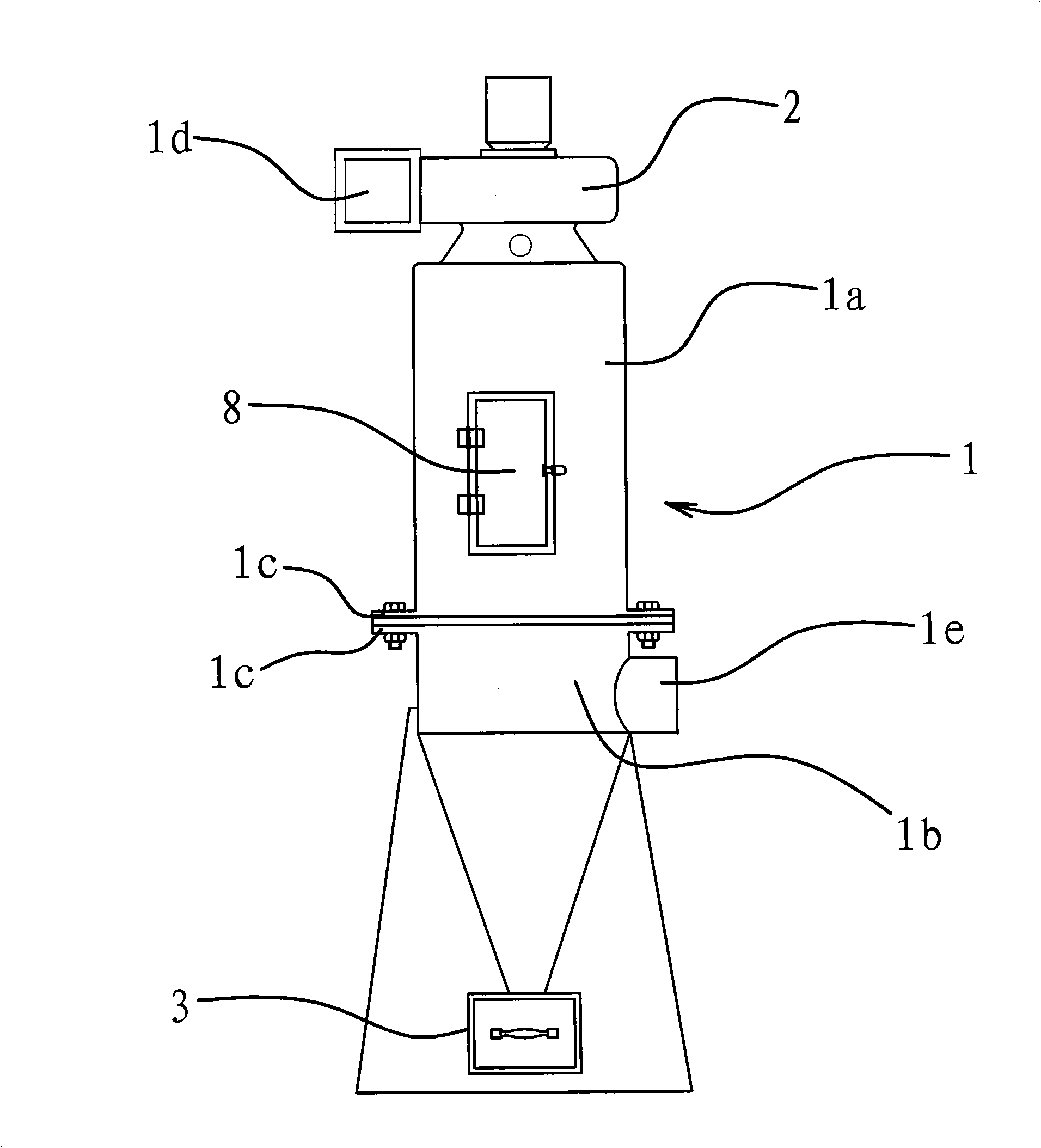

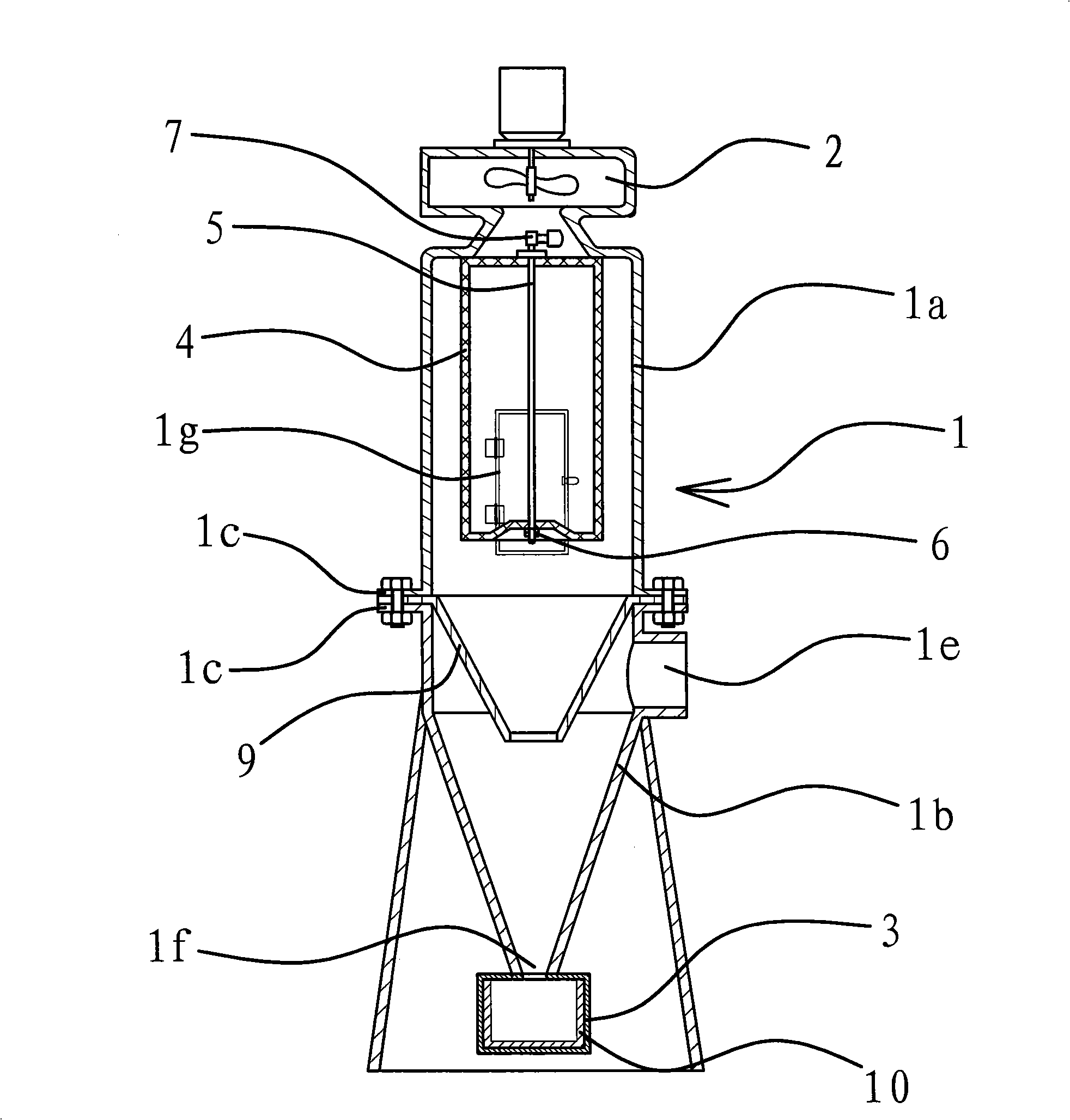

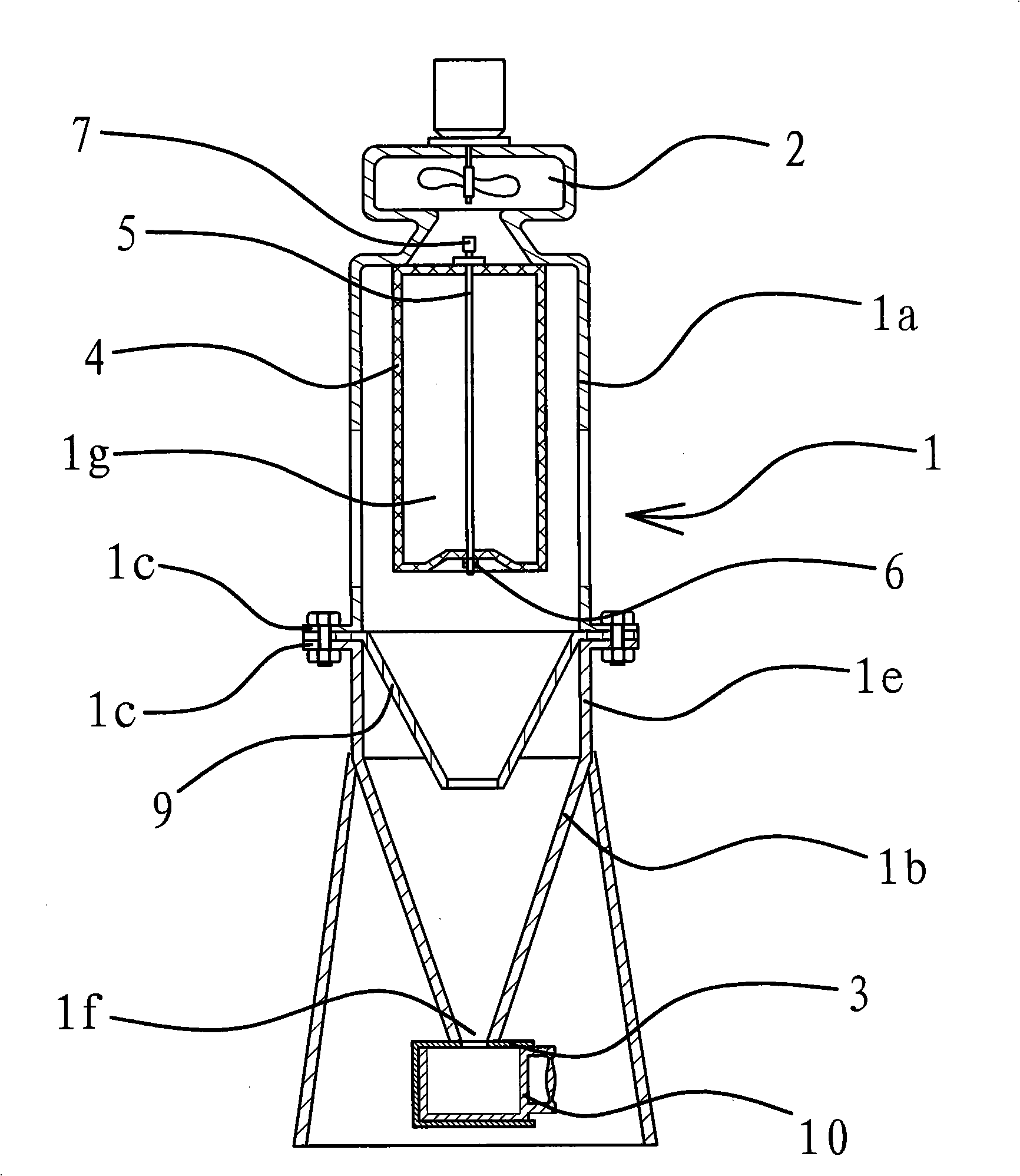

[0031] Such as figure 1 As shown, the cyclone filter cartridge dust collector is used to process dusty air, and it includes a housing 1 with a cavity inside.

[0032] The housing 1 is composed of an upper housing 1a and a lower housing 1b at the bottom of the upper housing 1a. The upper housing 1a has a flange 1b, and the lower housing 1b also has a flange 1c. The upper housing 1a and the lower housing The bodies 1b are connected via flanges 1c. An outlet 1d is provided on the upper part of the upper casing 1a, and a fan 2 is provided at the outlet 1d. The upper part of the lower casing 1b is provided with an inlet 1e, and both the inlet 1e and the outlet 1d communicate with the cavity in the casing 1 . The lower casing 1b is in the shape of a funnel with a large top and a small bottom, and the bottom of the lower casing 1b has a dust outlet 1f. In this embodiment, a dust box 3 is installed at the dust outlet 1f.

[0033] Such as figure 1 with figure 2 As shown, a filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com