Titanium dioxide nano-tube support with macroscopical shape and preparation method thereof

A technology of titanium dioxide and nanotubes, which is applied in the field of photocatalyst materials with macroscopic shapes and its preparation, can solve the problems of reduced catalyst amount, inconvenient regeneration, and impact on effluent water quality, and achieves the effect of easy separation and reduced dosing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

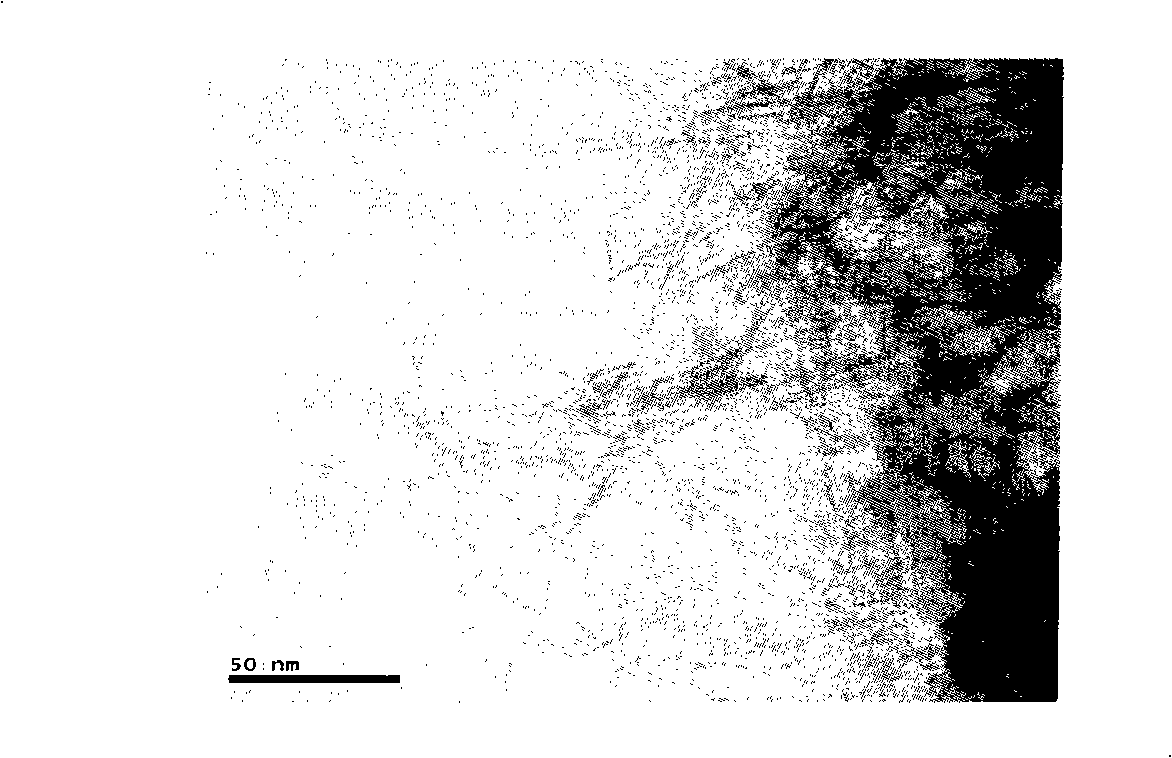

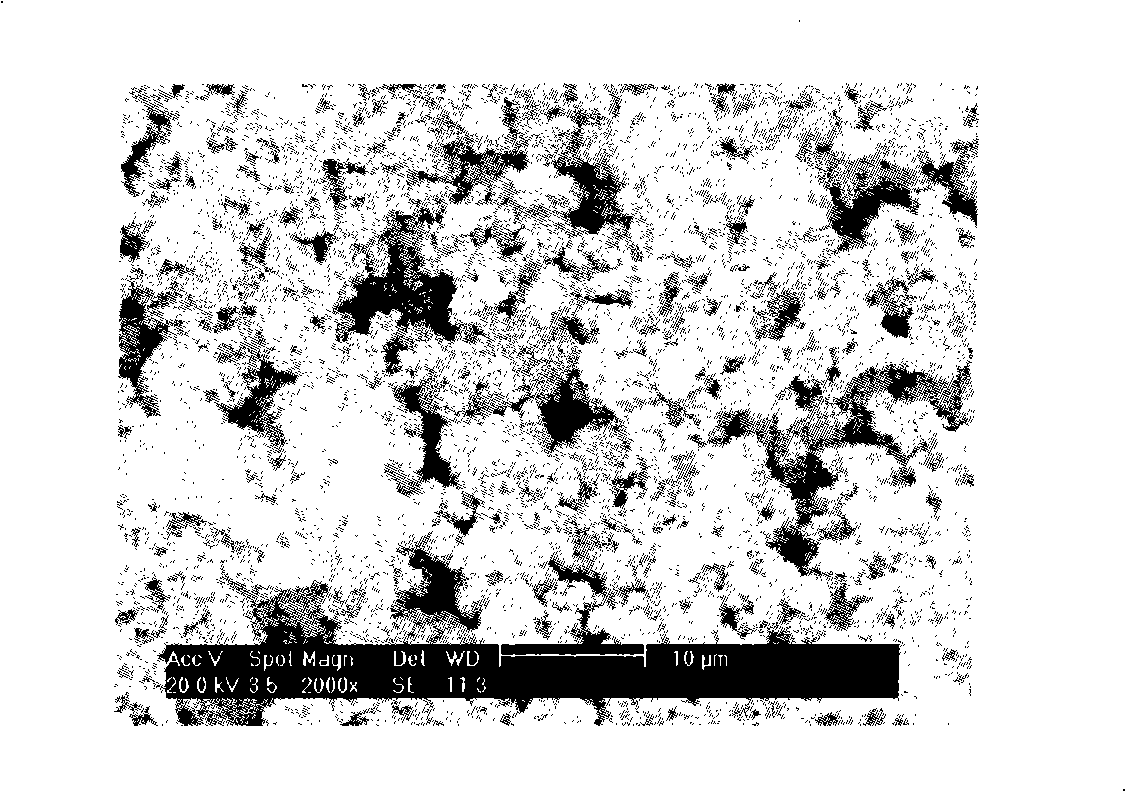

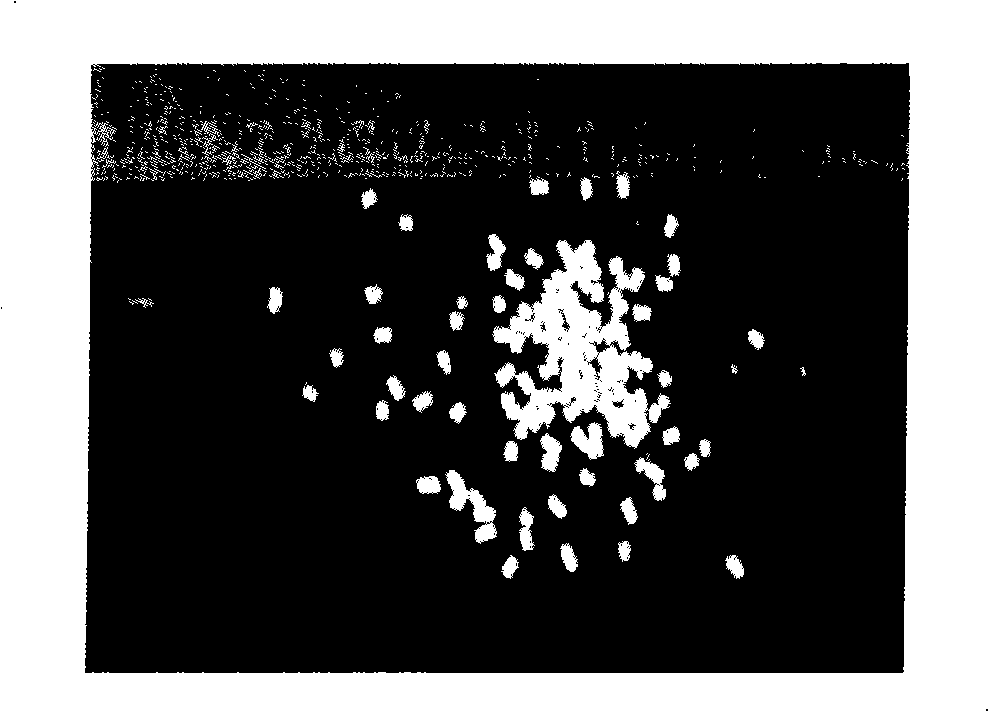

[0044] (1) Weigh 1g of P25, add 20mL of 10mol / L aqueous sodium hydroxide solution, stir for 0.5h, transfer to a polytetrafluoroethylene-lined reactor, react at 100°C for 20h, and wash with water until neutral.

[0045] (2) Use 0.1 mol / L hydrochloric acid to adjust the pH value of the solution obtained in step (1) to be less than 3, soak for 0.5 h, and wash with water until neutral.

[0046] (3) Concentrate the solution obtained in step (2) so that its water content is 50%.

[0047] (4) Transfer the concentrated solution prepared in step (3) into a mold, and dry at 60° C. under normal pressure for 7 hours.

[0048] (5) Calcining the solid titania support prepared in step (4), the calcination temperature is 300° C., and the calcination time is 7 hours, to obtain a titania nanotube support with a macroscopic shape.

Embodiment 2

[0050] (1) Weigh 5g of P25, add 50mL of 15mol / L aqueous sodium hydroxide solution, stir for 0.8h, transfer to a polytetrafluoroethylene-lined reactor, react at 100°C for 25h, wash with water until neutral.

[0051] (2) Use 0.5 mol / L hydrochloric acid to adjust the pH value of the solution obtained in step (1) to be less than 3, soak for 0.8 h, and wash with water until neutral.

[0052] (3) Concentrate the solution obtained in step (2) so that its water content is 45%.

[0053] (4) Transfer the concentrated solution prepared in step (3) into a mold, and dry under normal pressure at 70° C. for 5 hours.

[0054] (5) Calcining the solid titania support prepared in step (4), the calcination temperature is 700° C., and the calcination time is 5 h, to obtain a titania nanotube support with a macroscopic shape.

Embodiment 3

[0056] (1) Weigh 7g of P25, add 60mL of 20mol / L aqueous sodium hydroxide solution, stir for 1h, transfer to a reaction kettle lined with polytetrafluoroethylene, react at 120°C for 25h, wash with water until neutral.

[0057] (2) Use 0.5 mol / L sulfuric acid to adjust the pH value of the solution obtained in step (1) to be less than 3, soak for 1 hour, and wash with water until neutral.

[0058] (3) Concentrate the solution obtained in step (2) so that its water content is 60%.

[0059] (4) Transfer the concentrated solution prepared in step (3) into a mold, and dry under normal pressure at 60° C. for 6 hours.

[0060] (5) Calcining the solid titania support prepared in step (4), the calcination temperature is 400°C, and the calcination time is 6h, to obtain a titania nanotube support with a macroscopic shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com