Ring roll mill apparatus

A ring roller mill and roller technology, which is used in the field of inorganic non-metallic material grinding, can solve the problems of difficult rolling and directional introduction into a certain position, and achieve the effects of reducing fluidity, promoting comprehensive utilization, and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, characteristics and effects of the present invention, the following examples are given and described in detail in conjunction with the accompanying drawings as follows:

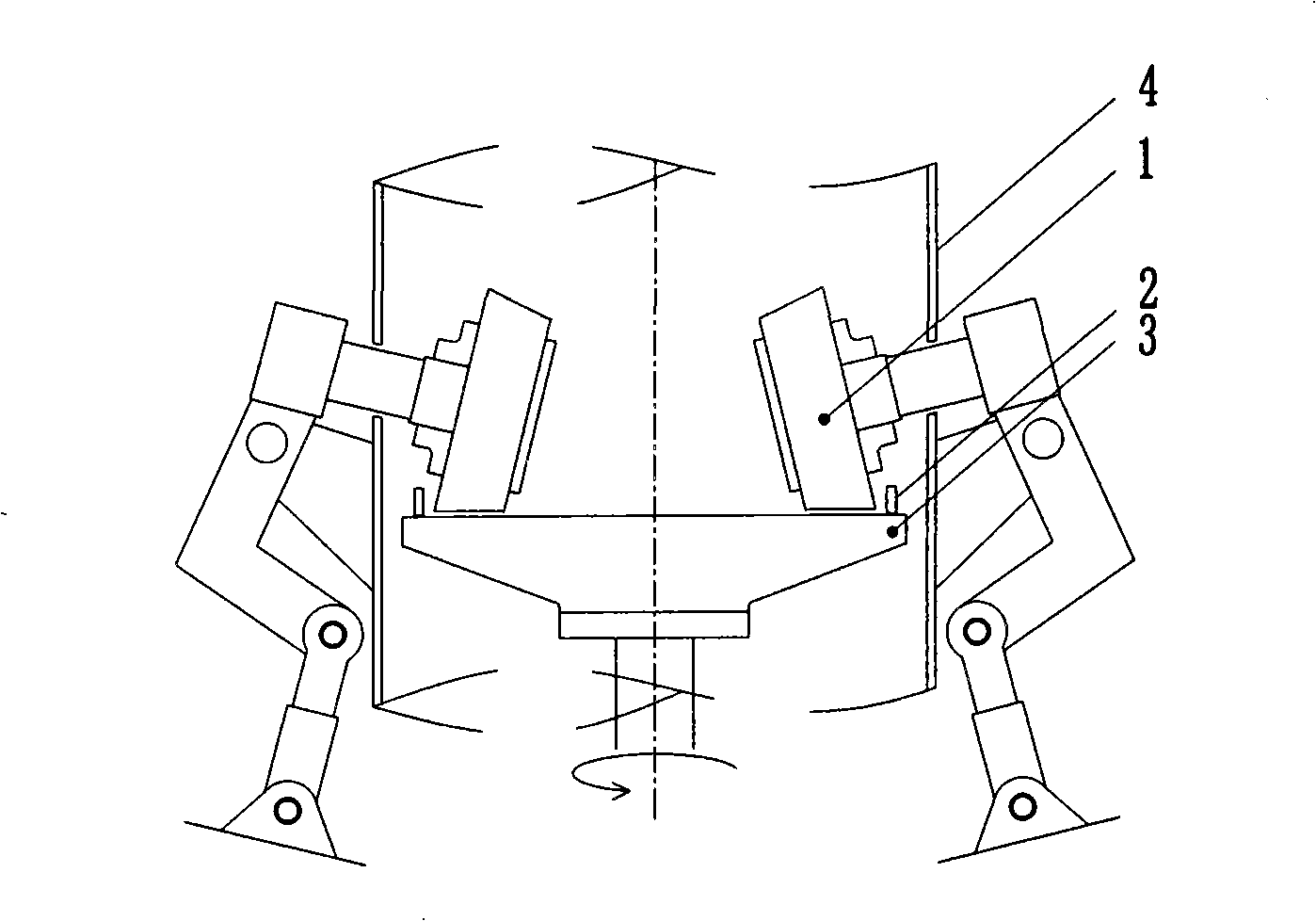

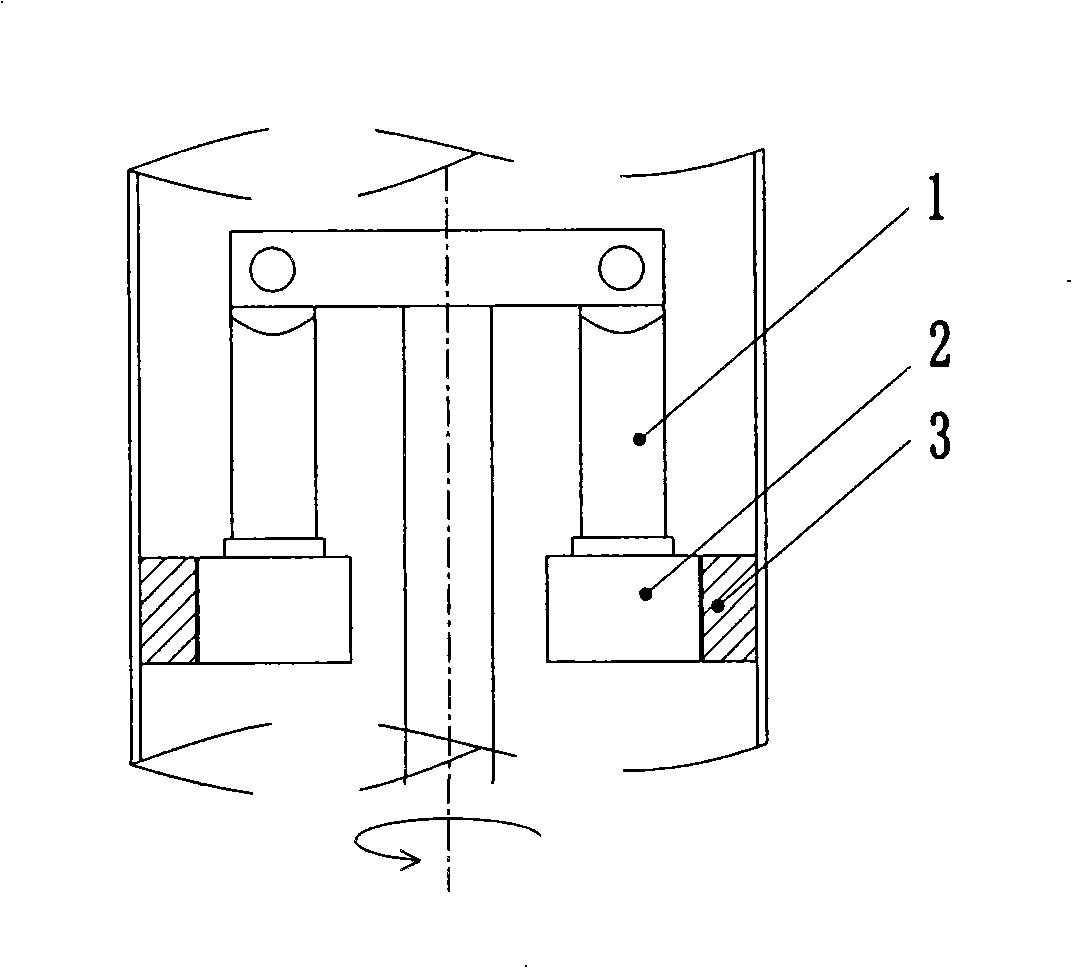

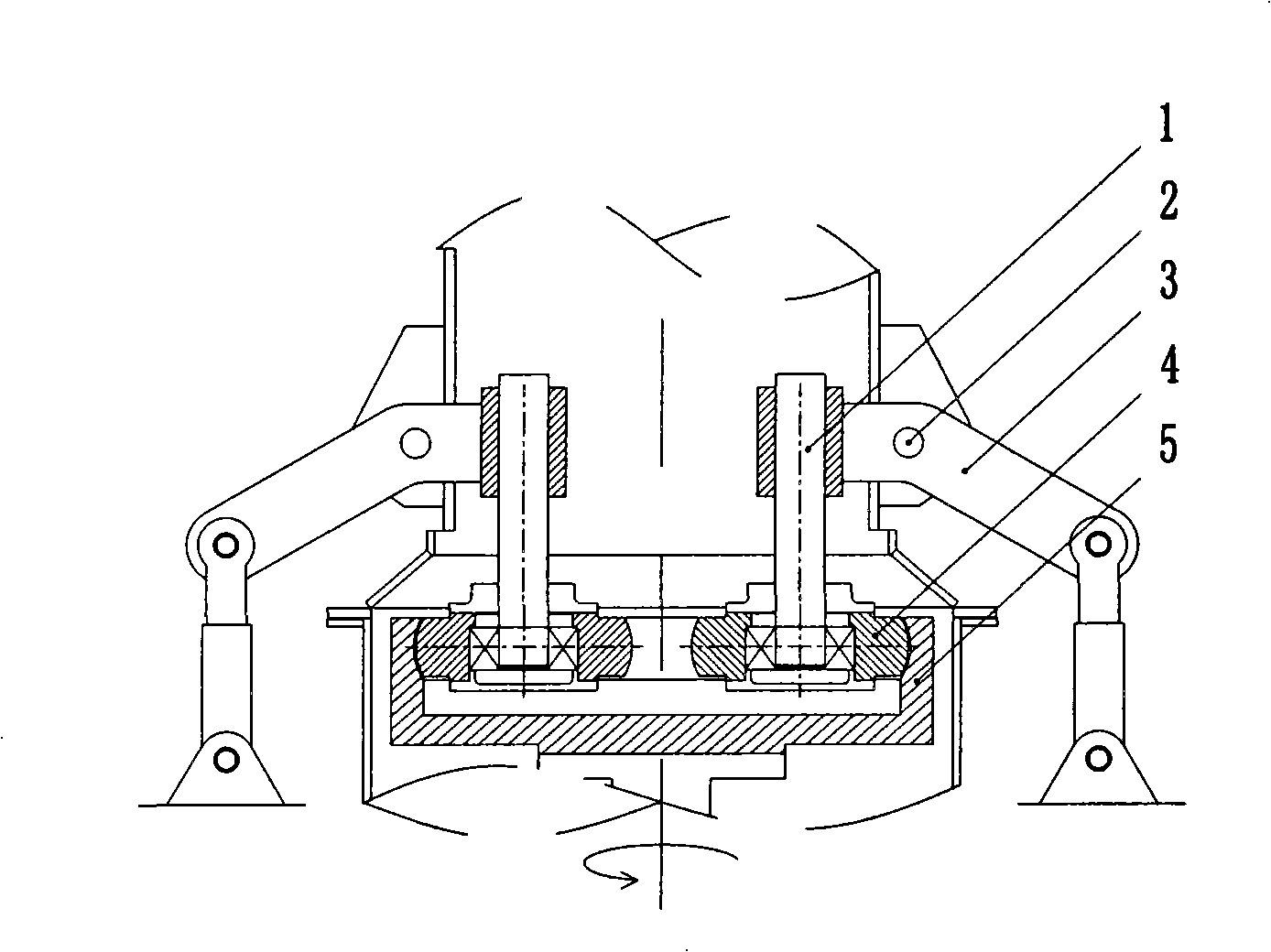

[0022] Please refer to the attached image 3 , a ring roller grinding device, one end of a roller shaft 1 is tightly connected to a roller arm 3 connected with a support shaft 2, and the other end is connected to a roller 4 placed in a grinding ring 5. The grinding ring 5 is a circular ring with a bottom, and an arc-shaped groove is arranged around the inner wall of the circular ring, and the structure of the groove matches the roller 4 . The integral body of the roller arm 3 and the roller shaft 1 that is firmly connected can swing around the support shaft 2 . When running without material, the center line of the roller shaft 1 is perpendicular to the bottom surface of the grinding ring 5, and the roller 4 is tangent to the arc groove on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com