Combined sludge gas tank

A biogas tank and combined technology, applied to gas production bioreactors, waste fuels, etc., can solve the problems of inconvenient feeding and discharging, difficult to guarantee quality, short service life, etc., and achieve convenient transportation and installation, good sealing effect, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

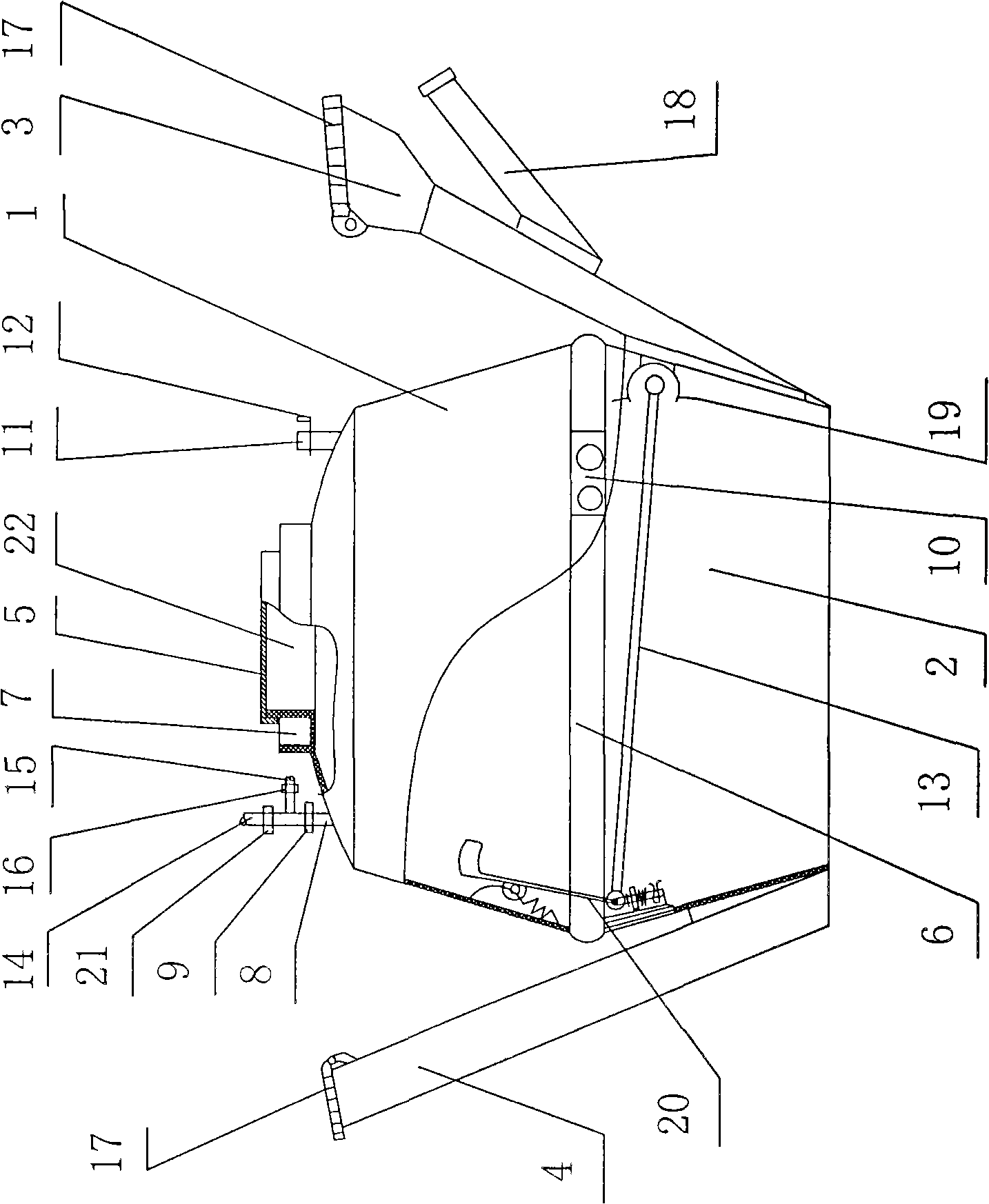

[0012] The combined biogas tank is composed of an upper tank body 1, a lower tank body 2, a feed pipe 3, a slag discharge pipe 4, a gas tank cover 5 and a locking hoop 6. Upper tank body 1 and lower tank body 2 are connected and locked by locking band 6 and locking bolt 10, and the effect of locking band 6 is to prevent the dislocation of the upper and lower tank bodies, and the second is to play a sealing role after installation. The upper and lower tanks can also adopt other connection and installation methods, such as flange connection. The feed pipe 3 and the slag discharge pipe 4 are respectively installed on both sides of the lower tank body 2; the top of the upper tank body 1 is formed with an air tank mouth 22, the air tank mouth 22 is equipped with an air tank cover 5, and the outside of the air tank mouth 22 is formed with a Circle the groove 7; the tank body on one side of the groove 7 is shaped on an air pipe 11, and an air switch 12 is formed on the air pipe 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com