Product line for soft veins of leather

A production line and leather technology, applied in leather softening, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve problems such as long time and achieve consistent texture Natural, speed up production, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

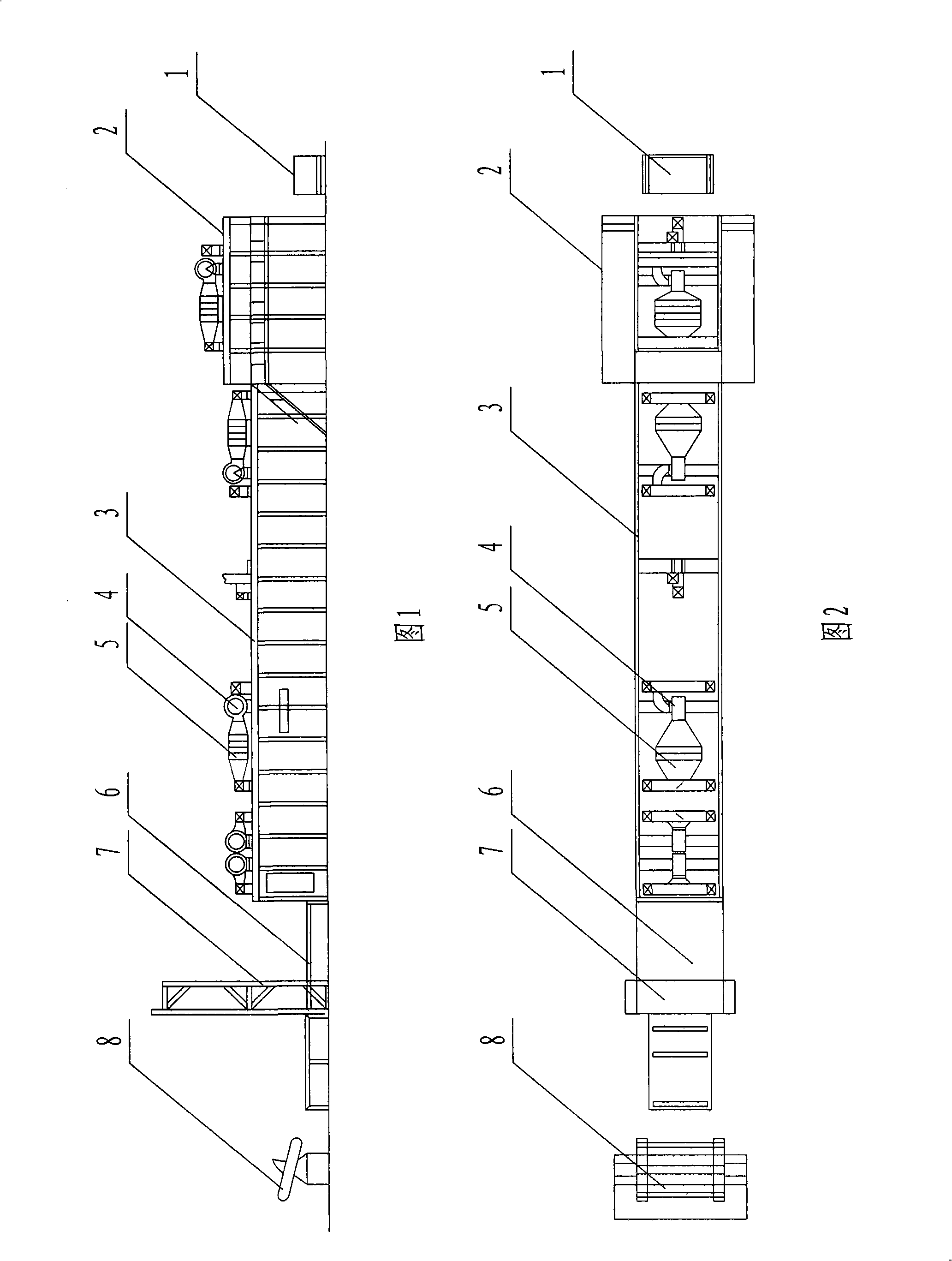

[0016] Below in conjunction with accompanying drawing 1,2, the leather soft kneading production line of the present invention is described in detail below.

[0017] As shown in the accompanying drawings 1 and 2, a leather soft kneading production line of the present invention, its structure includes an unwinder 1, a water tank 2, a kneading drum 3, a fan 4, a heat exchanger 5, a pallet 6, a breaker The frame 7 and the crimping machine 8 are characterized in that the leather is unrolled into the water tank 2 through the unwinding machine 1, and the leather is in the water tank 2 after the water immersion, kneading, and squeezing processes. After the end, it is dried and cooled under the action of the fan 4 and the heat exchanger 5, and the dried and cooled leather enters the breaking frame 7 through the pallet 6 to complete the rag aligning process, and finally completes the winding through the curling machine 8. process.

[0018] The above-mentioned leather is also subjected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com