Integrated drill rig

A drilling rig and drilling boom technology, which is applied in the field of comprehensive drilling rigs and roadway excavation engineering, can solve the problems of single implementation, few functions, and low efficiency, and achieve the effect of multiple functions, single power, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

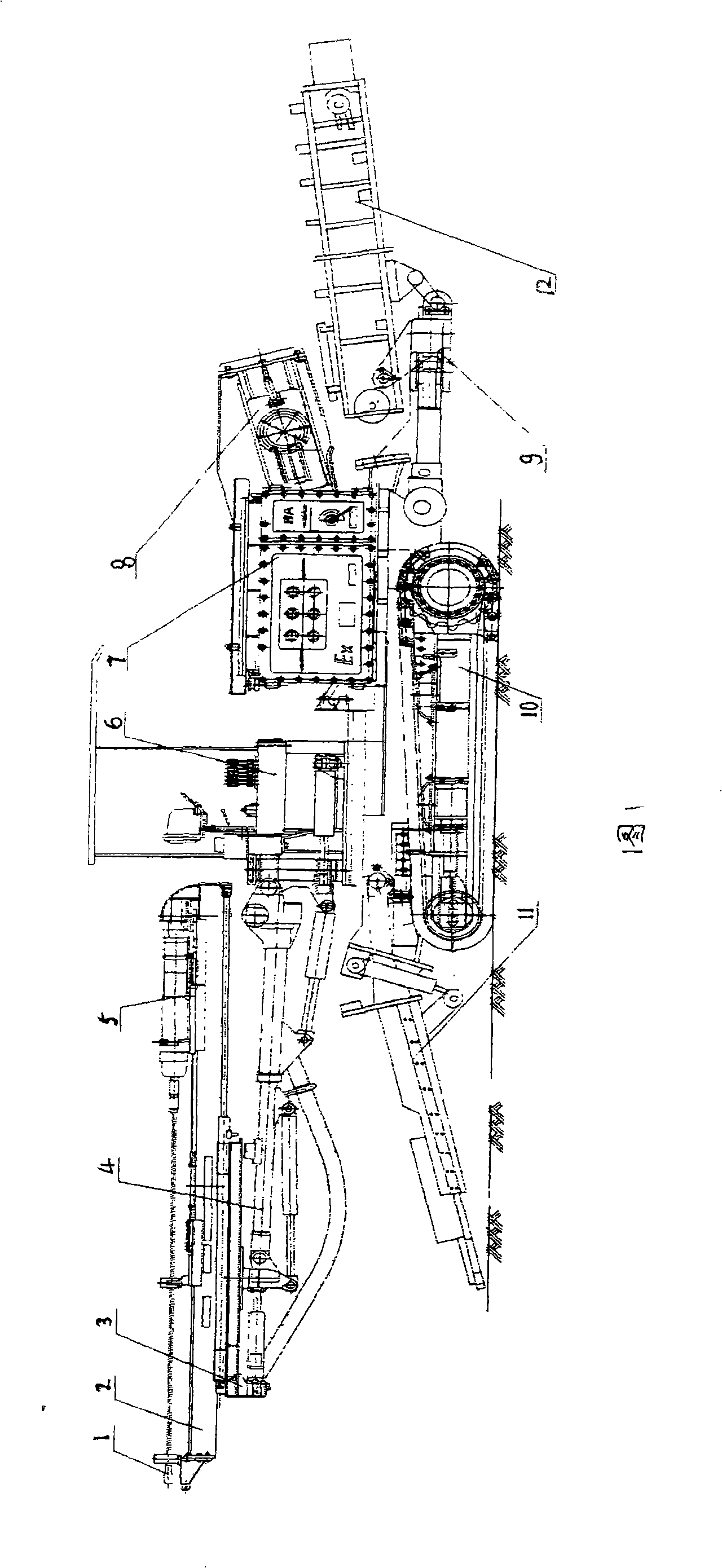

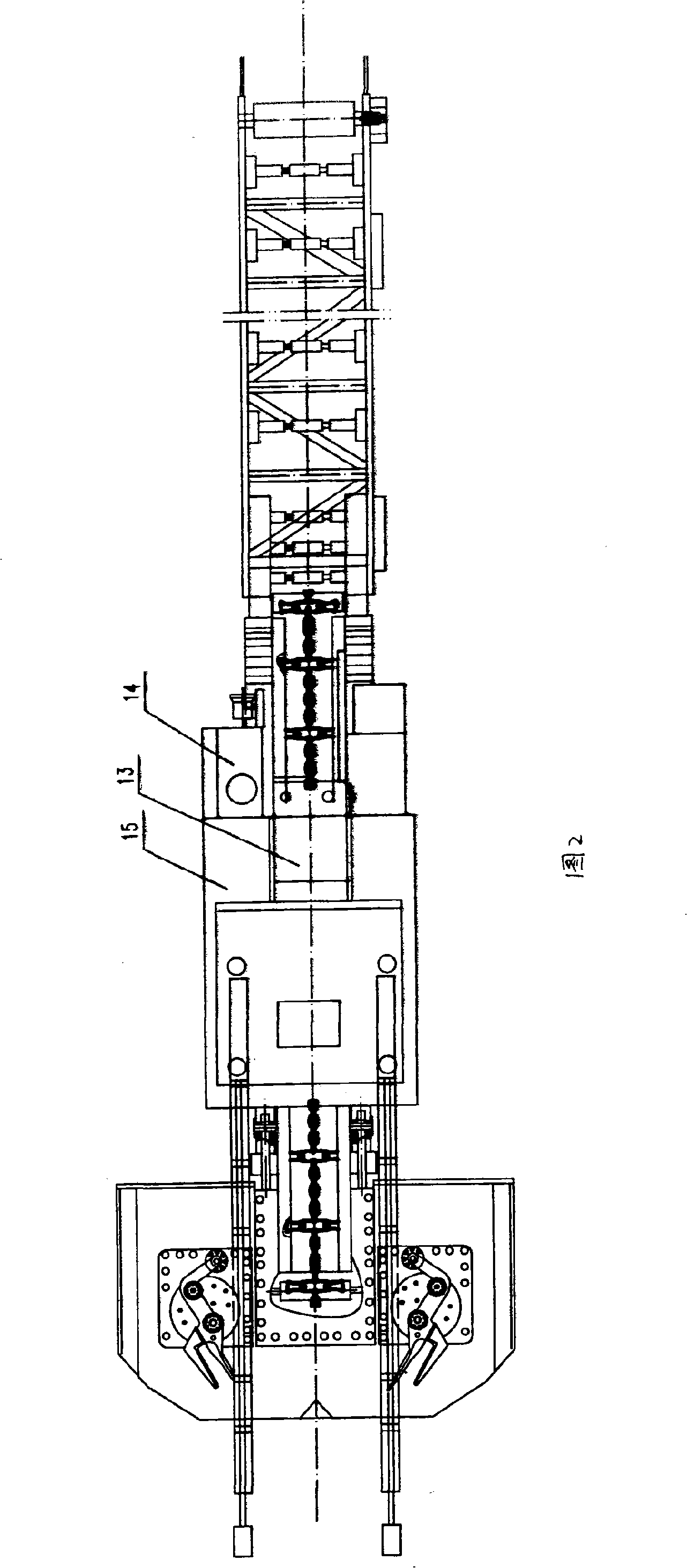

[0034] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0035]Shown in accompanying drawing 1: it comprises walking chassis 19, hydraulic rock drilling device, electric control box 7, hydraulic power mechanism motor 14 and console 6, and hydraulic rock drilling mechanism is arranged on the top of walking chassis 10 front ends, and it comprises hydraulic rock drilling machine 5, The drilling arm 4 and the rock drilling machine 4 are set on the drilling arm 4 through the hydraulic propeller 2 and the slideway compensation orientation device 3. The drilling arm 4 is hinged to the drilling arm seat arranged on the traveling chassis. The loading mechanism is composed of a loading part and a scraper conveyor. The loading part rakes materials onto the conveyor scraper or conveyor belt on the scraper conveyor and transfers them to the carrier at the rear of the drilling rig. The walking chassis 10 is a crawler-type walking chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com