Boiler heat supplying climate compensating system and its implementing method

A climate compensation and boiler technology, which is applied in heating systems, hot water central heating systems, heating methods, etc., can solve the problems of large investment in transformation, acid corrosion of boilers, and small flow of boilers, so as to avoid the danger of pipe explosion and improve the efficiency of transformation Convenience and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

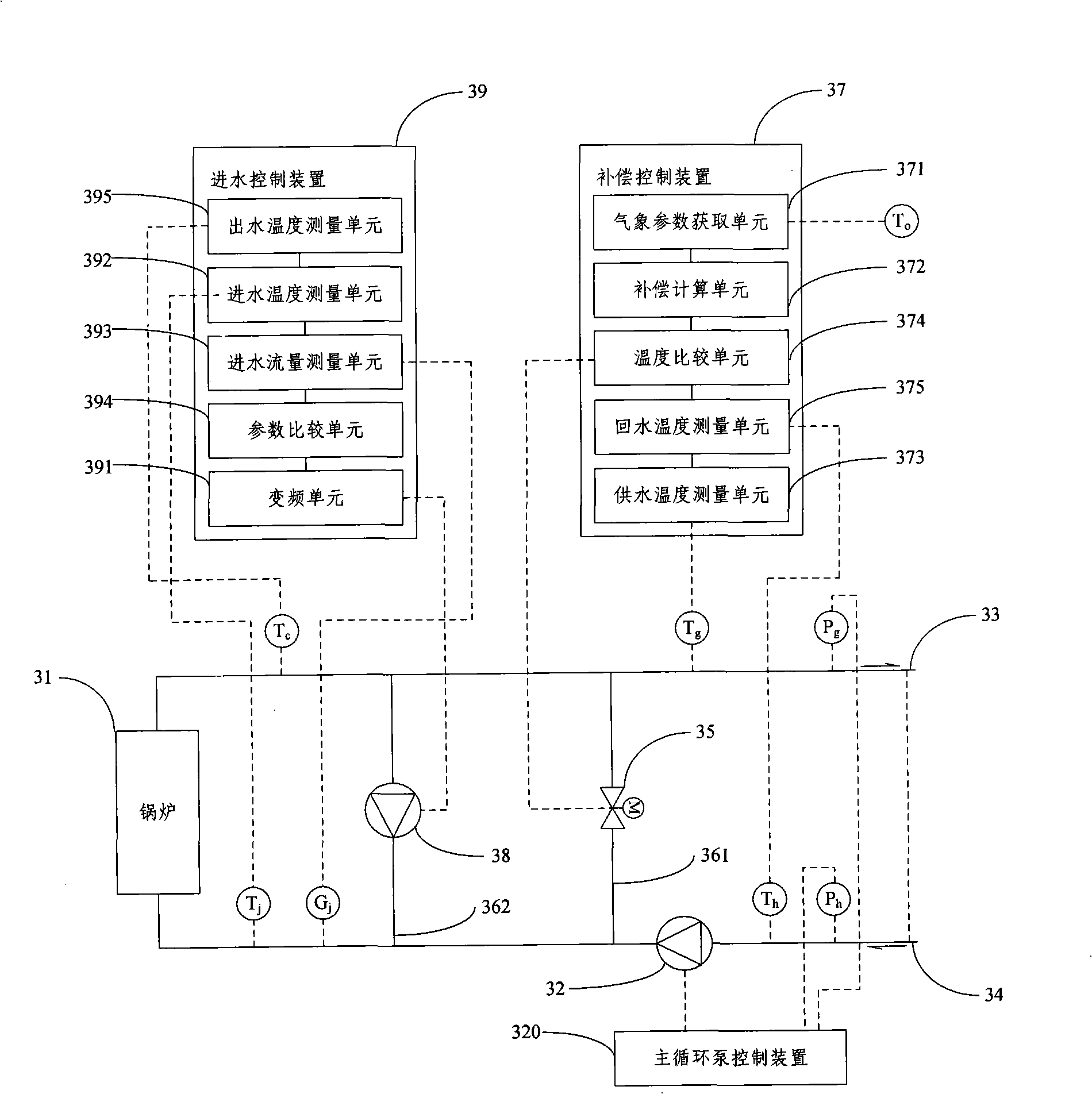

[0049] image 3 It is a schematic diagram of Embodiment 1 of the boiler heating climate compensation system of the present invention. As shown in the figure, the system includes a boiler 31, a main circulation water pump 32 for system water supply and system return water circulation, a water supply pipe 33 connected to the boiler water outlet, And the return pipe 34 that is connected with boiler water inlet, also includes:

[0050] The electric regulating valve 35 is arranged on the first bypass pipe 361 connecting the water supply pipe 33 and the return pipe 34, and is used to adjust the mixing ratio of the system return water flowing into the boiler outlet water; the compensation control device 37 is calculated according to the obtained outdoor meteorological parameters The heating temperature reference value is compared with the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com