Novel prestressed duct grouting material and preparation method thereof

A technology of channel grouting and prestressing, which is applied in the field of civil engineering construction, can solve problems such as poor mechanical properties and durability, and achieve the effects of improving early strength and crack resistance, reducing pollution and increasing interfacial bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

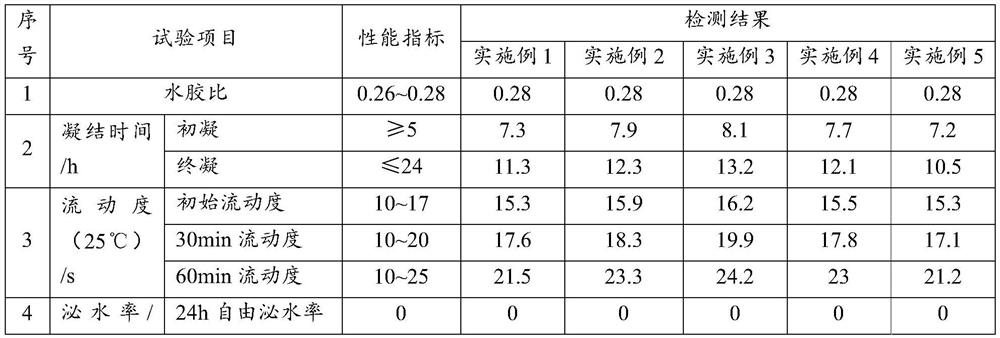

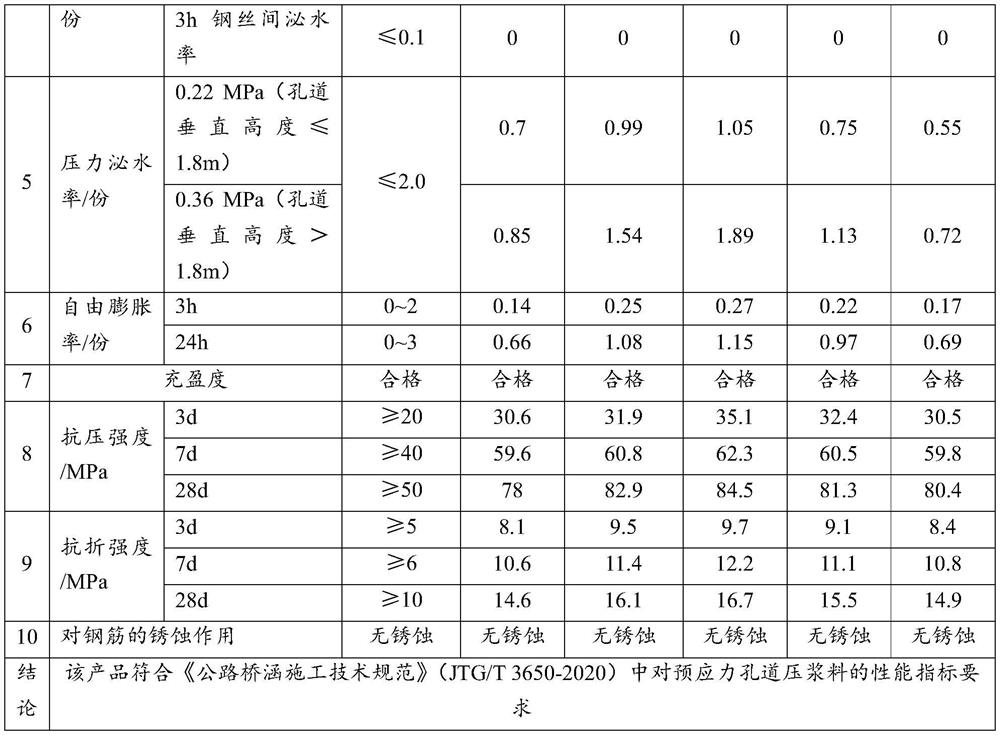

Examples

Embodiment 1

[0027] This example provides a new type of prestressed pore-pressing slurry, which includes the following components in parts by weight: 62 parts of PO42.5 cement, 15 parts of phosphorus slag powder, 4 parts of rock cuttings, and 3.5 parts of coal gangue Powder, 6.5 parts of porous microsilica powder, 1.5 parts of polymer water absorbent resin, 0.4 parts of aminomethyl propanol, 0.4 parts of modified polyvinyl alcohol fiber, 4 parts of polycarboxylate superplasticizer, 1 part Emulsified silicone oil defoamer.

Embodiment 2

[0029] This example provides a new type of prestressed pore pressure slurry, which includes the following components in parts by weight: 64 parts of PO42.5 cement, 14 parts of phosphorus slag powder, 5 parts of rock cuttings, and 3 parts of coal gangue powder, 6.2 parts of porous microsilica powder, 1.3 parts of polymer water-absorbing resin, 0.3 parts of benzoic acid monoethanolamine, 0.3 parts of modified polyvinyl alcohol fiber, 3 parts of polycarboxylate superplasticizer, 0.8 parts of Polysiloxane defoamer.

Embodiment 3

[0031] This example provides a new type of prestressed pore-pressing slurry, which includes the following components in parts by weight: 65 parts of PO42.5 cement, 13 parts of phosphorus slag powder, 6 parts of rock cuttings, and 2.5 parts of coal gangue powder, 6 parts of porous microsilica powder, 1.2 parts of polymer water-absorbing resin, 0.2 parts of monoethanolamine benzoate, 0.3 parts of modified polyvinyl alcohol fiber, 3 parts of sulfamate water reducer, 0.5 parts of Emulsified silicone oil defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com