Optimization technique of circulating water body conveying system

A technology of conveying system and water body, applied in the field of optimization of circulating water body conveying system, can solve the problems of waste, increase of system ineffective energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

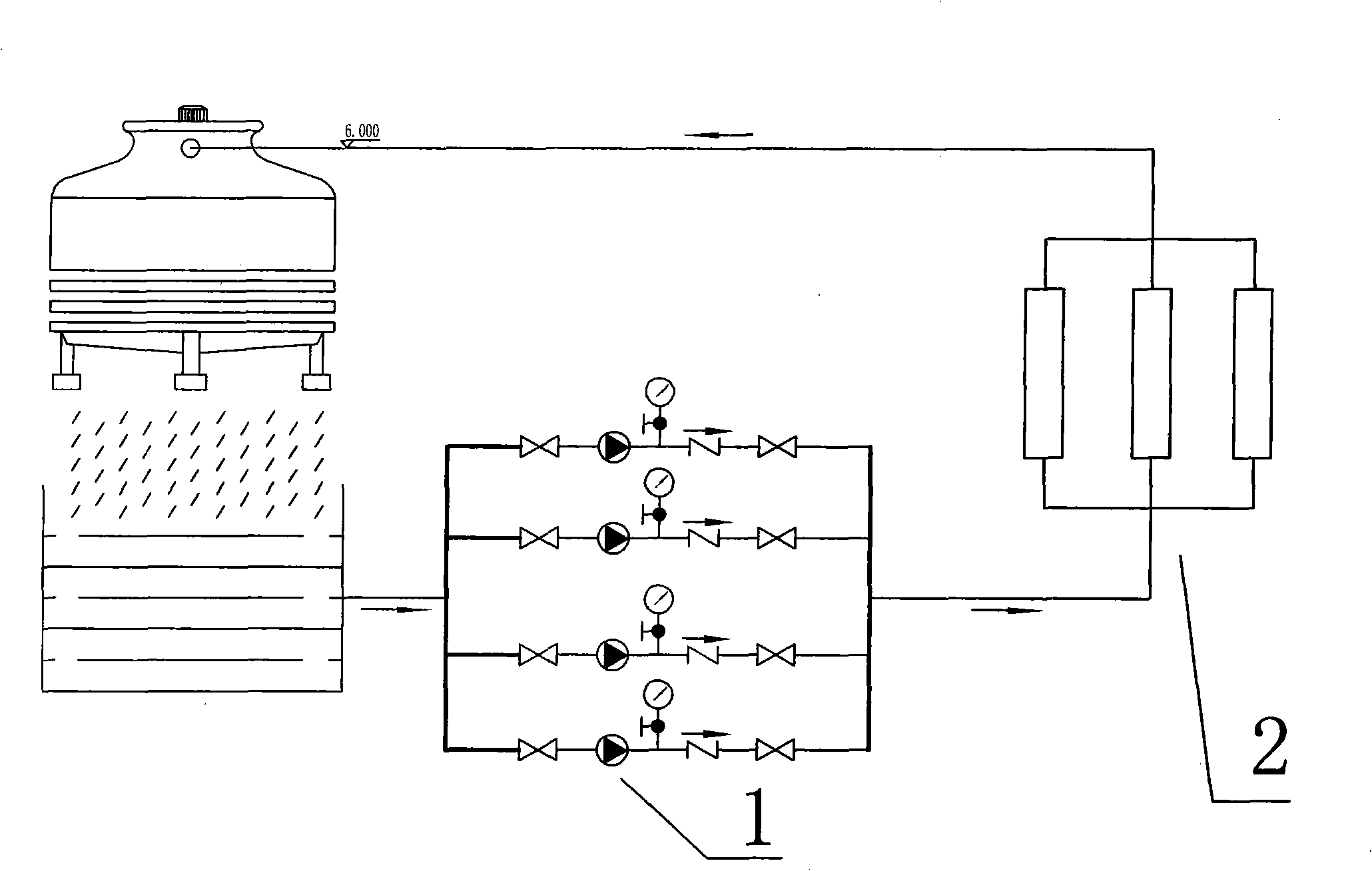

[0037] Embodiment 1, with reference to figure 1 As shown, the central air-conditioning water delivery system optimization technology includes three steps:

[0038] 1. Data collection of central air-conditioning water supply system, which includes cooling water pump 1 and chiller unit 2. The pressure of cooling water pump 1 is collected through a high-precision pressure gauge. The pressure of existing cooling water pump 1 is 0.35MPa, with a pressure punch Collect data on the inlet and outlet pressure of pipe sections, valves and chillers, and collect data on the inlet and outlet temperature of chiller 2 through an infrared thermometer. The existing temperature difference is 3°C;

[0039] 2. The analysis technology of the central air-conditioning water supply system is to establish the model of the central air-conditioning water supply system, and the analysis content is to calculate the pressure through the formula: H=h f + h d + h s + h m

[0040] Calculate the pressure o...

Embodiment 2

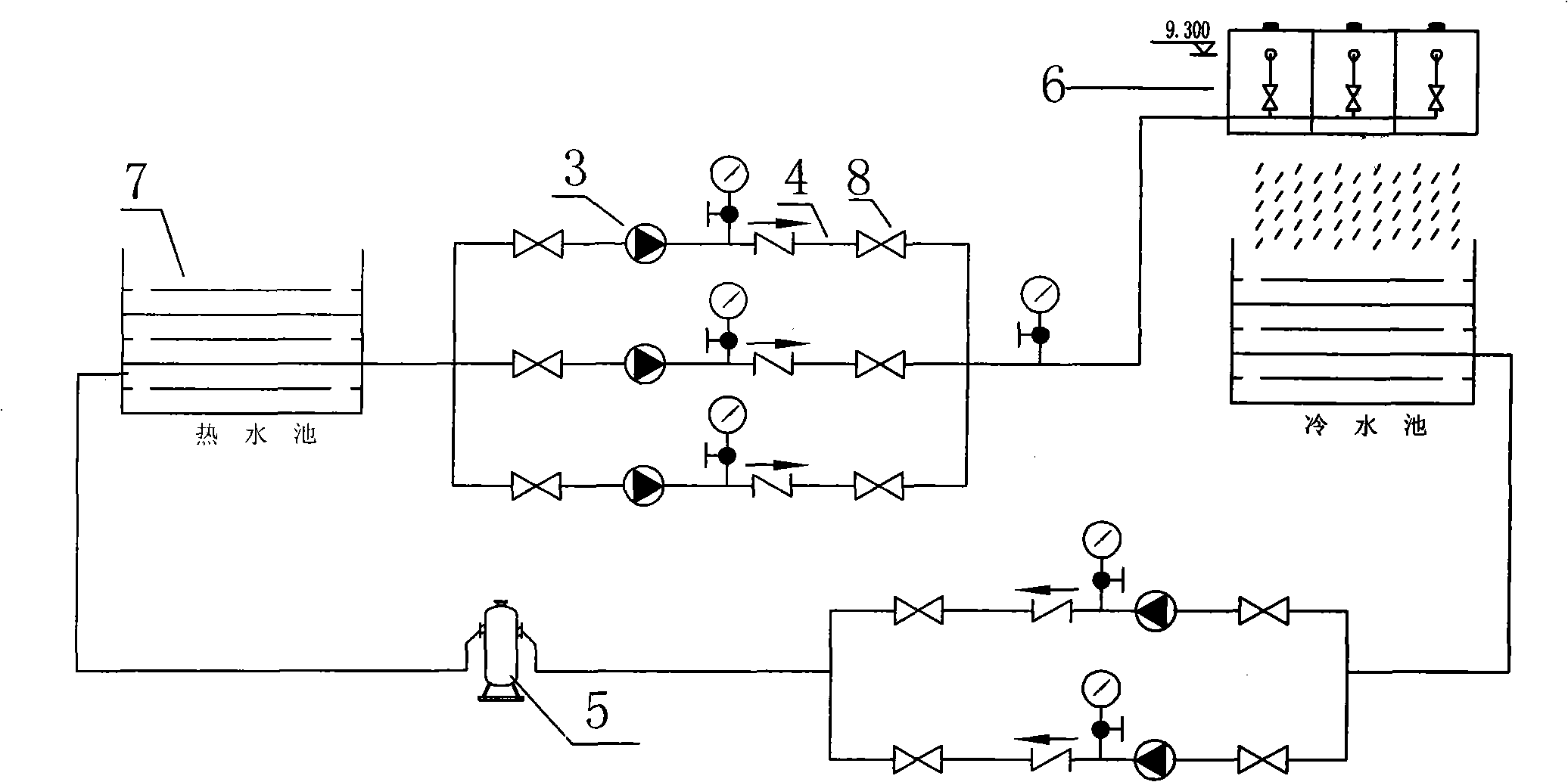

[0042] Embodiment 2, with reference to figure 2 As shown, the blast furnace return water system optimization technology includes three steps:

[0043] 1. Data collection of the backwater system of the blast furnace, data collection of the pump station 3, pipeline 4, terminal equipment 5, cooling tower 6, and water pool 7 through tools. The high-precision pressure gauge collects data on the outlet pressure of the hot water pump in the pumping station 3, the pressure puncher collects data on the pressure behind the valve 8, the ultrasonic flowmeter collects data on the water volume of the system, and the multi-functional electric energy meter monitors the actual consumption of the motor. Power for data collection.

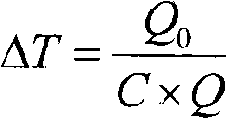

[0044] 2. Blast furnace backwater system analysis technology, establish a backwater system model, the analysis content is to calculate the head of the cooling water pump through the pressure calculation formula, H=h 1 + h 2 + h 3 + h 4 =9.3+1+1+2=13.3m,

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com