Controllable multi-component cathode arc plasma forming apparatus and method

A technology of plasma and cathode arc, which is applied in the direction of plasma, electrical components, discharge tubes, etc., can solve problems such as the difficulty in making composite targets, achieve simple adjustment of component types and densities, simple processing and preparation, and avoid difficult production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

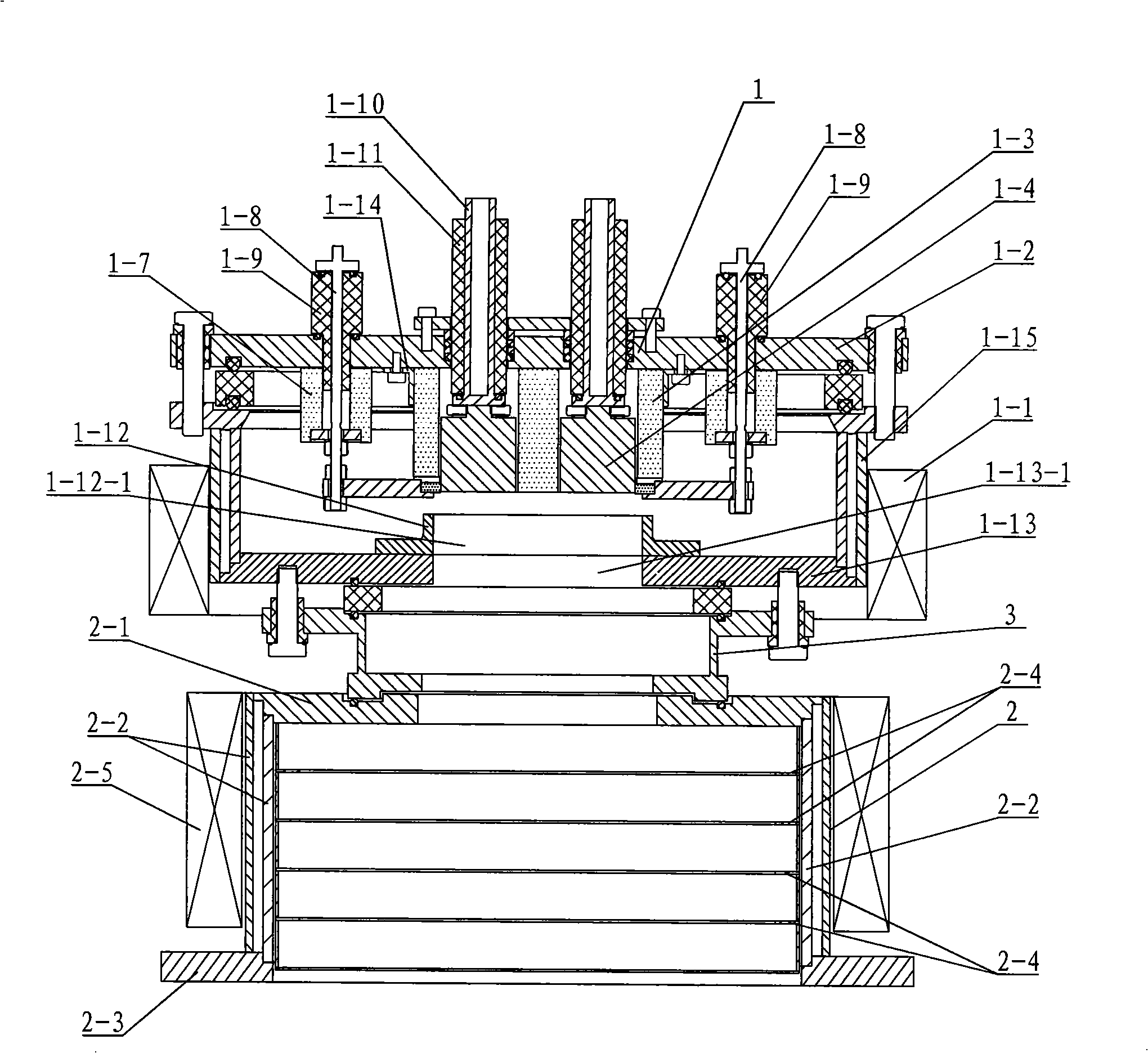

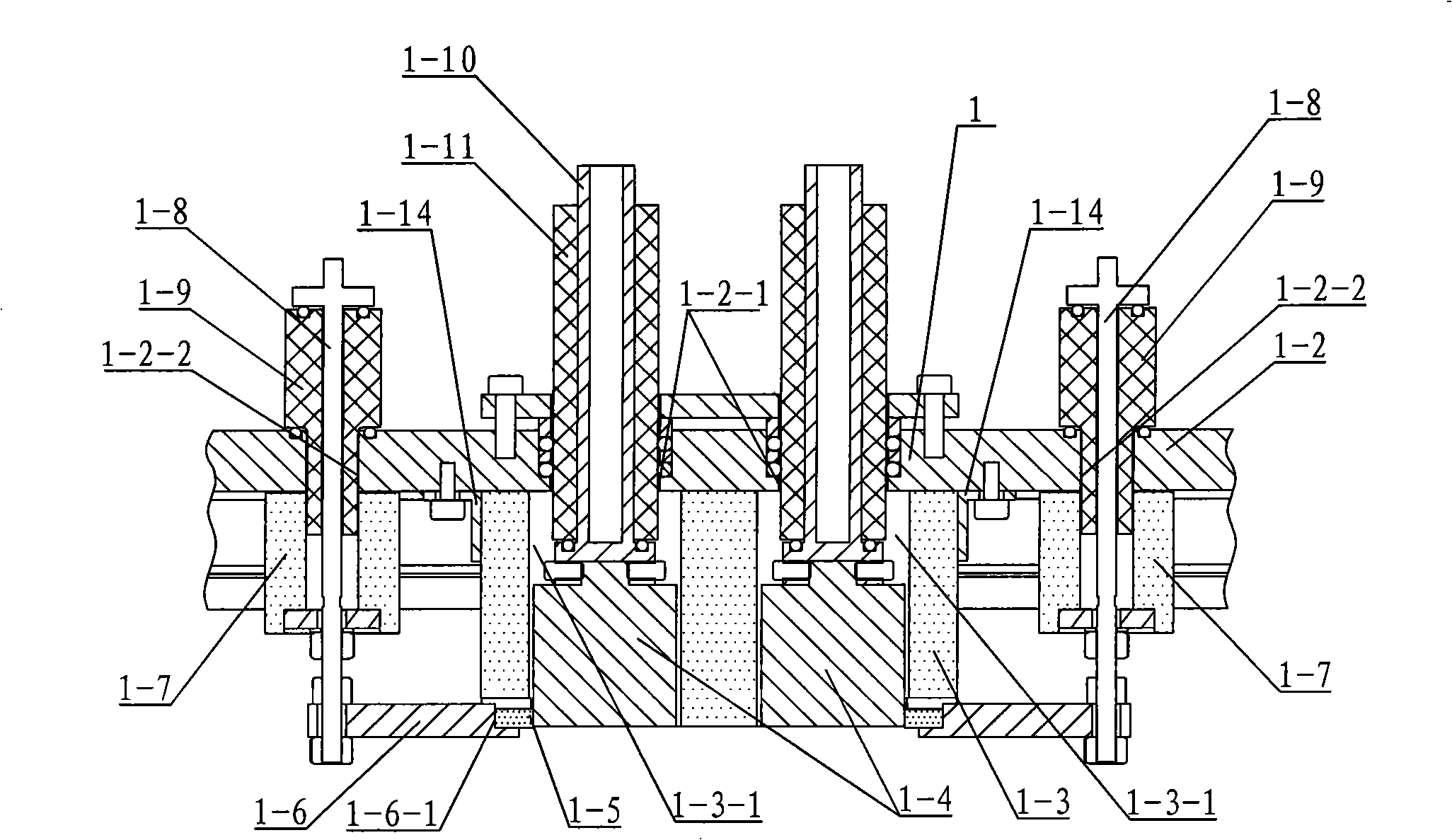

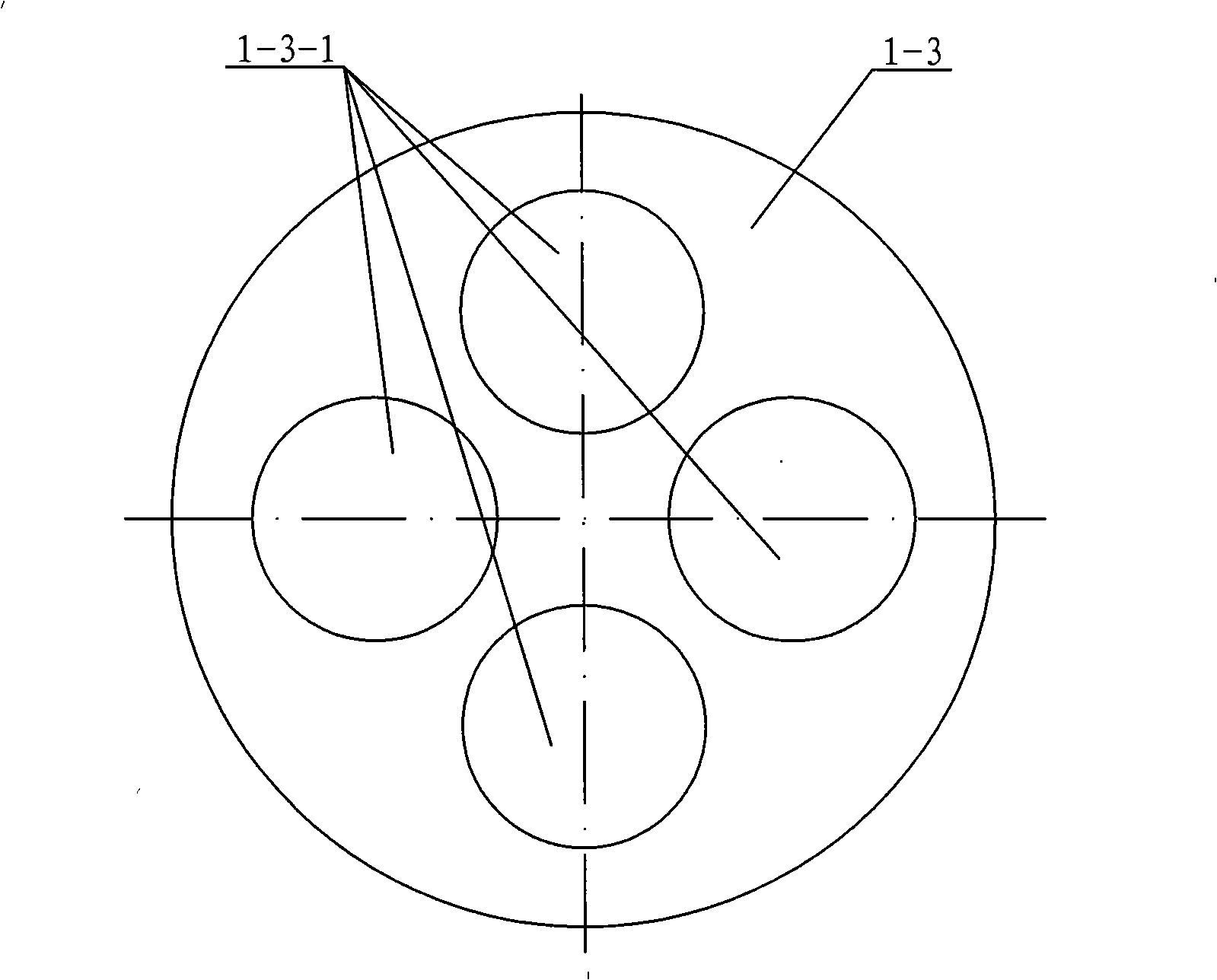

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment is made up of discharge chamber 1, filter chamber 2 and connection pipe 3, the upper end of connection pipe 3 is connected with the lower end of discharge chamber 1, the lower end of connection pipe 3 is connected with the upper end of filter chamber 2, discharge chamber 1 consists of a magnetic field coil 1-1, an upper cover 1-2, a cathode protection sleeve 1-3, a cathode 1-4, a trigger insulating block 1-5, a trigger plate 1-6, a trigger rod insulating sleeve 1-7, and a trigger rod 1 -8. Composed of trigger rod outer casing 1-9, cathode seat 1-10, cathode insulating sleeve 1-11, anode 1-12, anode seat 1-13, cathodic protection sleeve seat 1-14 and anode cylinder 1-15, The upper cover 1-2 is provided with a cathode seat hole 1-2-1 and a trigger rod hole 1-2-2, and the cathode protection sleeve 1-3 is provided with a cathode hole 1-3-1, and the cathode protection sle...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment, the cathode seat hole 1-2-1 and the trigger rod hole 1-2-2, the cathode 1-4, the trigger insulating block 1-5, the trigger plate 1-2 on the upper cover 1-2 of the present embodiment 6. The number of trigger rod insulating sleeves 1-7, trigger rods 1-8, trigger rod outer casings 1-9, cathode seats 1-10, and cathode insulating sleeves 1-11 is four to six. This design makes the cathodes 1-4 mutually isolated and connected with different discharge power sources externally, and the discharge current of each cathode 1-4 can be adjusted independently. In this way, the composition of the multivariate mixed plasma in the region of the anode port can be changed by selecting different cathode materials, and the density of the components in the multivariate mixed plasma can be achieved by controlling the discharge current of different cathodes. In addition, 4-6 cathodes 1-4 can obtain a plasma densit...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 Describe this embodiment, the cathode seat hole 1-2-1 and the trigger rod hole 1-2-2, the cathode 1-4, the trigger insulating block 1-5, the trigger plate 1-2 on the upper cover 1-2 of the present embodiment 6. There are four trigger rod insulating sleeves 1-7, trigger rods 1-8, trigger rod jackets 1-9, cathode seats 1-10, and cathode insulating sleeves 1-11. This value is to make the plasma density formed by the cathode arc discharge obtained by cathodes 1-4 optimal, so that the rate of film deposition is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com