VOC-free coating for wood

A wood and paint technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of paint mechanical quality, poor weather resistance, etc., and achieve the effect of simple components, reasonable collocation, easy production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

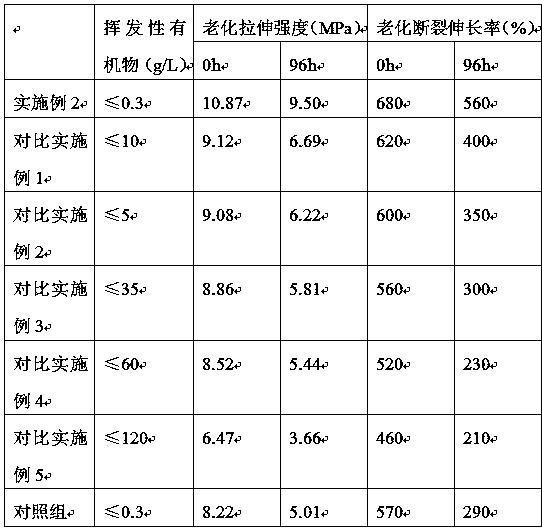

Examples

Embodiment 1

[0030] A zero-VOC paint for wood is prepared from the following parts by weight:

[0031] 30 parts acrylic emulsion, 15 parts water dispersible polyisocyanate, 2 parts epoxidized soybean oil, 1 part antioxidant, 0.5 part sodium pyrophosphate, 1 part sodium dodecylbenzenesulfonate, 3 parts polyvinyl alcohol, 2 parts 1 part sodium carboxymethyl cellulose, 8 parts adsorption enhancing filler, 1 part defoamer, 150 parts water.

[0032] Further, the antioxidant is antioxidant 1010.

[0033] Further, the defoamer is an aqueous defoamer.

[0034] Further, the preparation method of the adsorption-enhancing filler comprises the following steps:

[0035] (1) Soak the conch shell powder in the acetic acid solution for 30s, take it out and rinse it with clean water for later use;

[0036] (2) Put the conch shell powder treated in step (1) into a calcining furnace for calcination treatment, control the calcination temperature to be 320 ° C, and take it out for use after 30 minutes;

[...

Embodiment 2

[0049] A zero-VOC paint for wood is prepared from the following parts by weight:

[0050] 33 parts of acrylic emulsion, 18 parts of water-dispersible polyisocyanate, 4 parts of epoxidized soybean oil, 1.5 parts of antioxidant, 1 part of sodium pyrophosphate, 2 parts of sodium dodecylbenzenesulfonate, 4 parts of polyvinyl alcohol, 3 parts of parts sodium carboxymethyl cellulose, 10 parts adsorption enhancing filler, 1.5 parts defoamer, 155 parts water.

[0051] Further, the antioxidant is antioxidant 168.

[0052] Further, the defoamer is an aqueous defoamer.

[0053] Further, the preparation method of the adsorption-enhancing filler comprises the following steps:

[0054] (1) First put the conch shell powder into the acetic acid solution for 33s, then take it out and rinse it with clean water for later use;

[0055] (2) Put the conch shell powder processed in step (1) into a calcining furnace for calcination treatment, control the calcination temperature to be 350 ° C, and ta...

Embodiment 3

[0068] A zero-VOC paint for wood is prepared from the following parts by weight:

[0069] 35 parts of acrylic emulsion, 20 parts of water-dispersible polyisocyanate, 5 parts of epoxidized soybean oil, 2 parts of antioxidant, 1.5 parts of sodium pyrophosphate, 3 parts of sodium dodecylbenzenesulfonate, 6 parts of polyvinyl alcohol, 4 parts of parts sodium carboxymethyl cellulose, 12 parts adsorption-enhancing fillers, 2 parts defoamer, 160 parts water.

[0070] Further, the antioxidant is antioxidant 1076.

[0071] Further, the defoamer is an aqueous defoamer.

[0072] Further, the preparation method of the adsorption-enhancing filler comprises the following steps:

[0073] (1) Soak the conch shell powder in acetic acid solution for 35s, take it out and rinse it with clean water for later use;

[0074] (2) Put the conch shell powder processed in step (1) into a calcining furnace for calcination treatment, control the calcination temperature to be 380 ° C, and take it out for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com