Pneumatic shell-breaking machine of walnut

A pneumatic shell cracking machine technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high labor intensity, high walnut damage rate, low productivity, etc., to reduce labor intensity, fast shell breaking speed, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

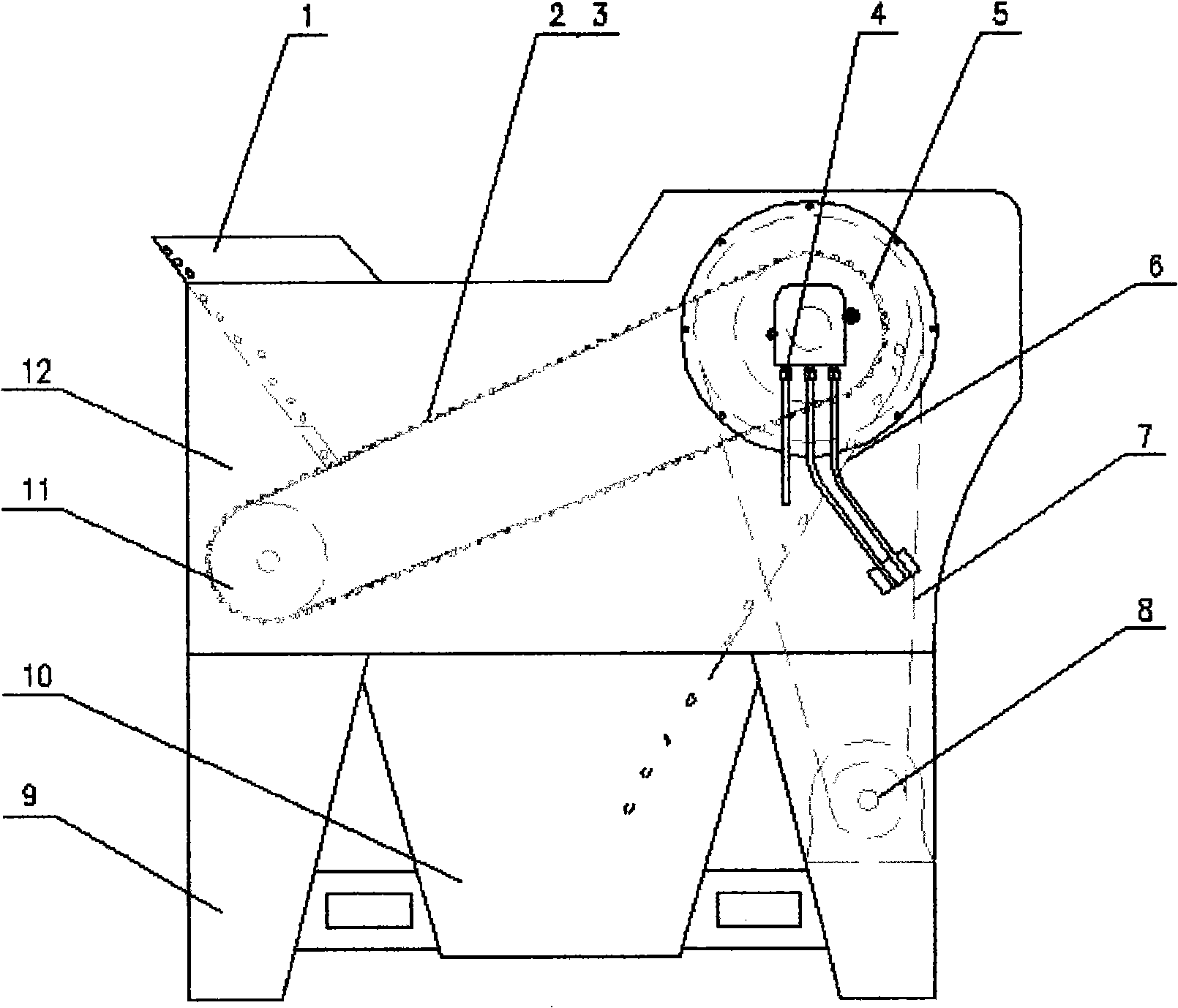

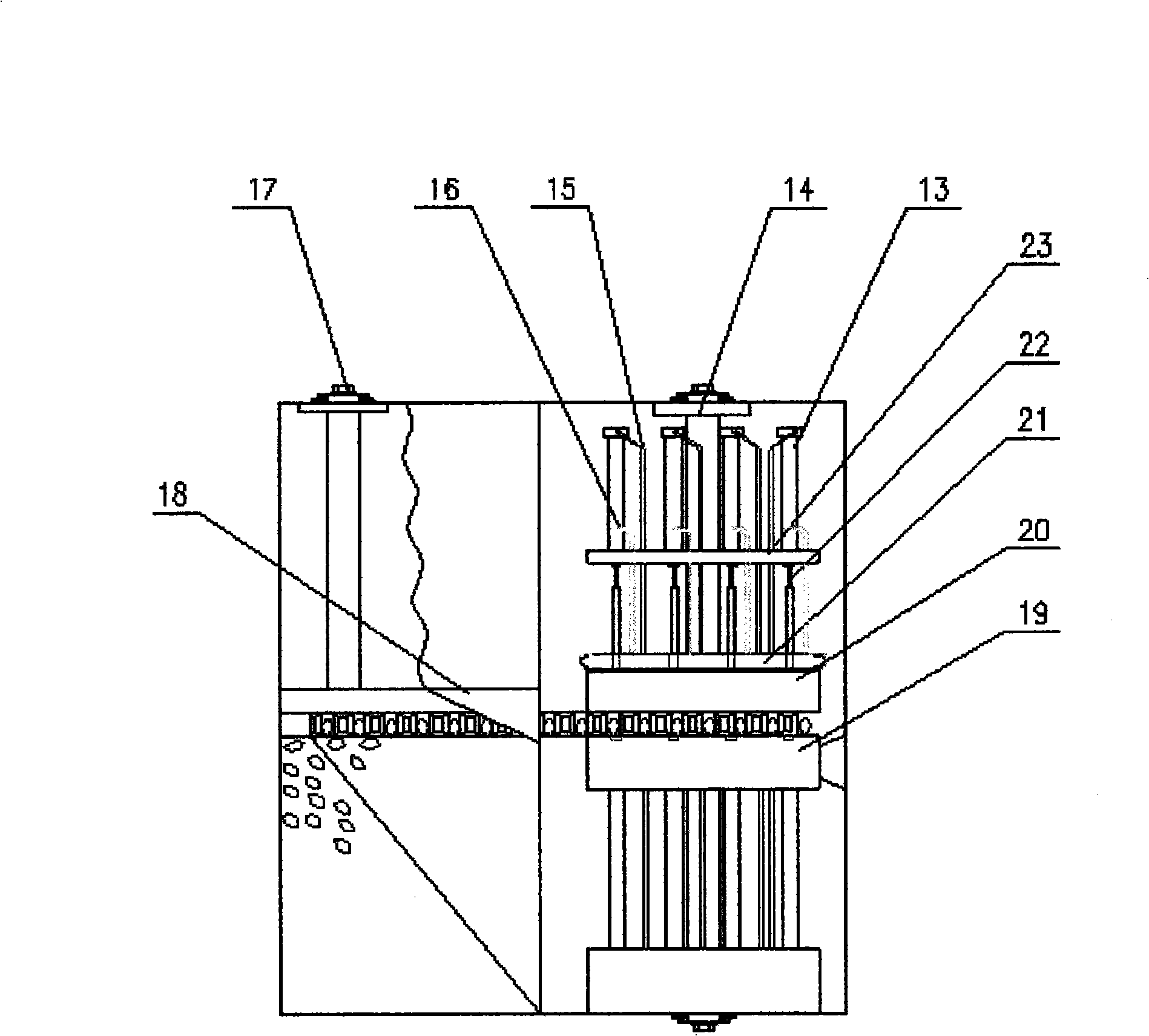

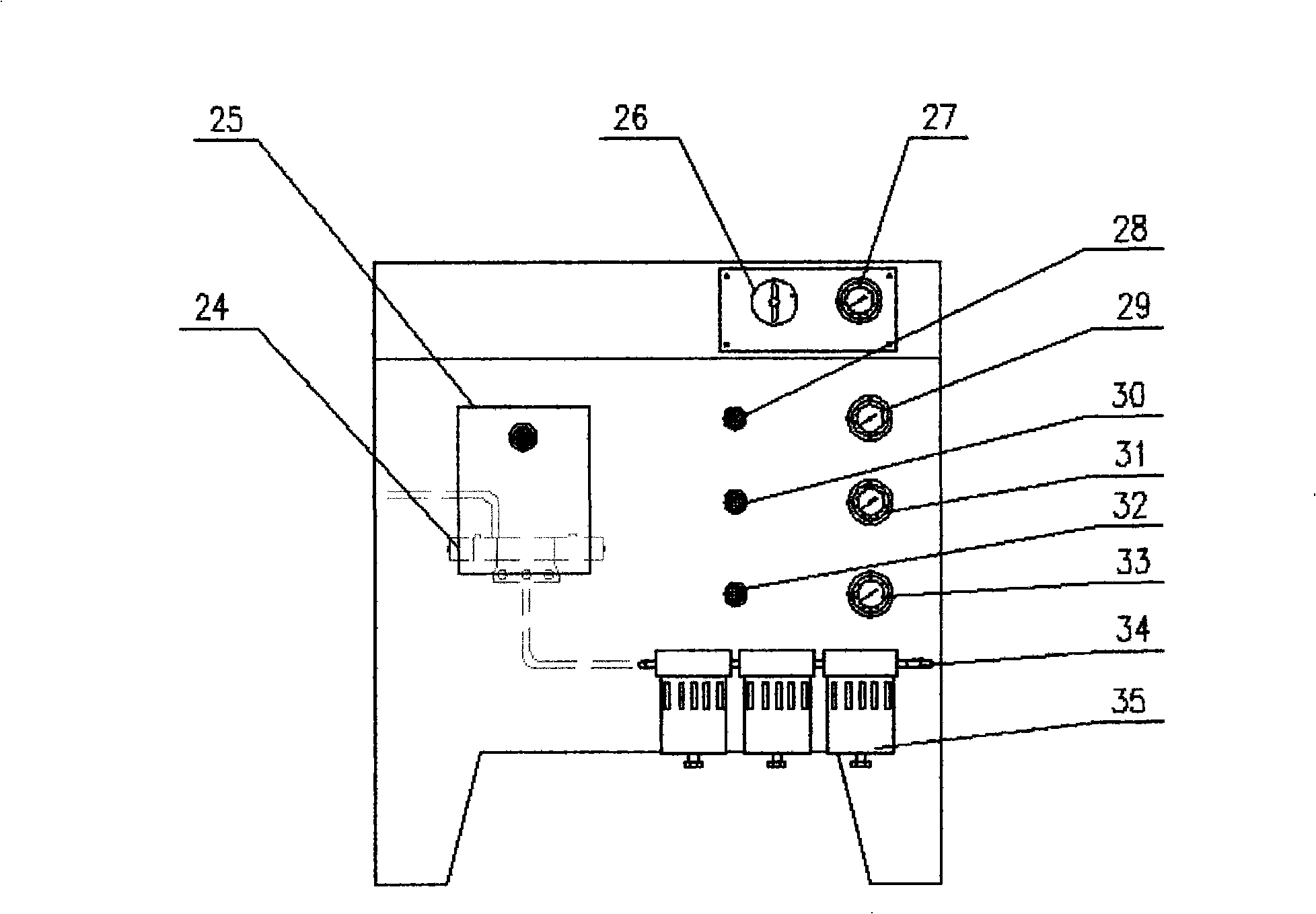

[0013] Legend: 1-feeding hopper; 2-conveyor chain; 3-positioning slot; 4-pressure relief tube; 5-sprocket 1; 6-guide hopper; 7-transmission chain; 8-motor; 9-outrigger; 10- Lower hopper; 11-sprocket 2; 12-frame; 13-small cylinder; 14-upper drive shaft; 15-breaking airflow pipe; 16-reset airflow pipe; 17-lower drive shaft; 18-limiting plate; 19-support seat; 20-air cavity; 21-sprocket 3; 22-air hammer; 23-support flange; 24-solenoid valve; 25-observation hole; 26-air pump switch; 27-air pump pressure gauge; 28 -Broken shell air pressure adjustment knob; 29-Broken shell air pressure display instrument; 30-Reset air pressure adjustment knob; 31-Reset air pressure display instrument; 32-Pressure relief adjustment knob; 33-Pressure relief display instrument; 34-Air pump connector; 35- air filter

[0014] The best example of the present invention will be described in detail below with reference to the accompanying drawings.

[0015] Attached figure 1 In the pneumatic walnut shelling ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com