Method for producing heat exchanger tube and heat exchanger device

A heat exchanger tube and manufacturing method technology, applied in indirect heat exchangers, heat exchanger types, chemical instruments and methods, etc., can solve the problems of low thermal efficiency and high cost, and achieve improved thermal efficiency, extended service life, and working conditions. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

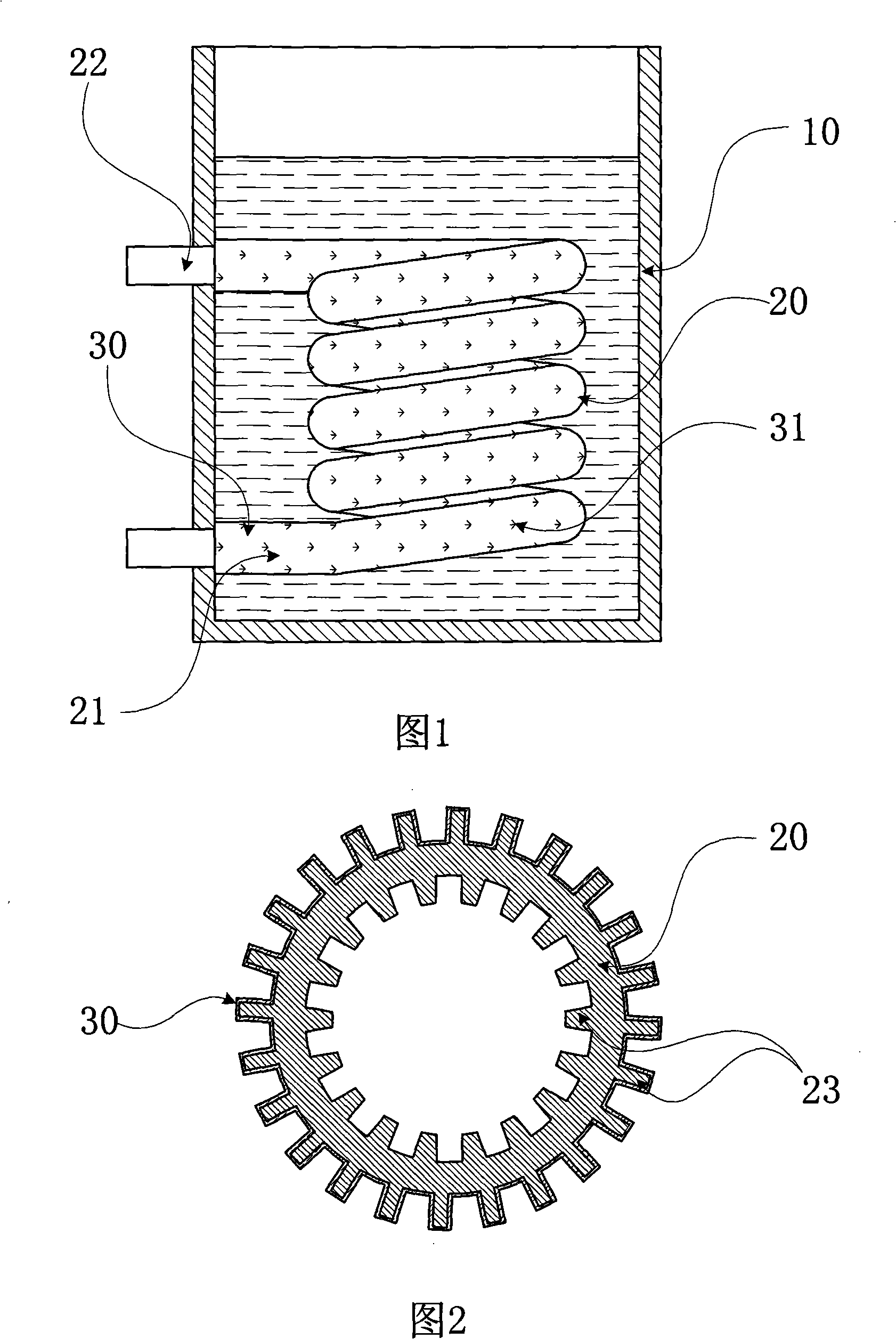

[0014] Specific embodiments of the present invention are described with reference to the above drawings.

[0015] As can be seen from Fig. 1 and Fig. 2, the manufacturing method of this heat exchanger tube comprises the following steps:

[0016] A. First select non-ferrous metals to make pipes, and divide them into heat exchange area and connection area;

[0017] B. Process a number of raised cooling fins on the surface of the tube heat exchange area;

[0018] C. Cover the outer surface of the heat exchange area with a thermally conductive protective layer.

[0019] The invention adopts non-ferrous metals to make heat exchanging elements. These non-ferrous metals have high thermal conductivity, and at the same time, they do not need to have extremely high heat resistance performance, which not only has good heat conduction effect, but also reduces costs. In addition, these non-ferrous metals also have excellent processing performance, can process more complex surface shapes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com