Method for polishing diamond rectangle micropore mold die hole

A microporous mold and diamond technology, which is used in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting shape, not suitable for rectangular hole mold polishing, polishing narrow-band twist fracture, etc., and achieve high polishing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

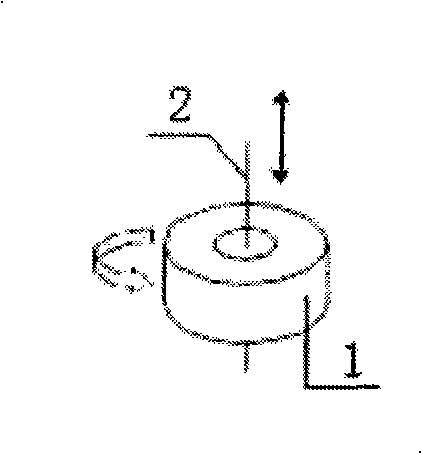

[0037] Such as Figure 4 As shown, the polishing method of the diamond rectangular microporous die hole provided by the present embodiment comprises the following steps:

[0038] Clamping the mold 1 into the fixture, adjusting the position of the mold 1 in the fixture, so that the direction of the polished surface of the mold is consistent with the polishing surface of the polishing narrow strip 2;

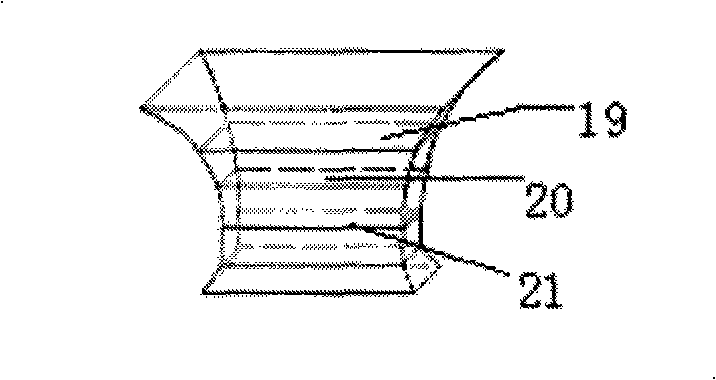

[0039] Clamp the polishing narrow belt 2 so that the normal line of the polishing narrow belt 2 is 0-25° to the wide side of the rectangular die hole, and make the deflection of the polishing narrow belt 2 when polishing the lubricating area 19 of the rectangular die hole, polishing the compression area 20 and polishing the size maintaining area 21 The angle is 0°, the upper wire clamp 17 and the lower wire clamp 18 move up and down at the same time to drive the polishing narrow 2 to reciprocate up and down to polish the rectangular die hole;

[0040] Adjust the upper line clamp ...

Embodiment 2

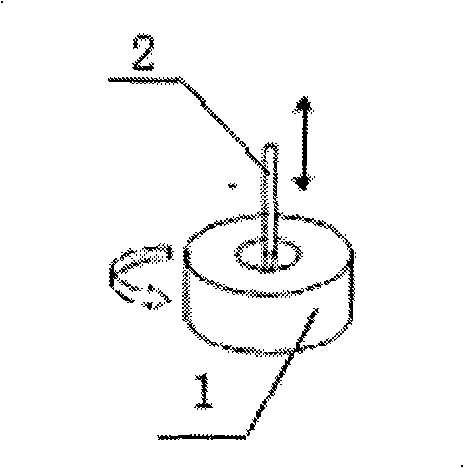

[0047] Such as Figure 5 As shown, the polishing method of the diamond rectangular microporous die hole provided by the present embodiment comprises the following steps:

[0048] Clamp the mold 1 into the fixture, adjust the position of the mold 1 in the fixture, so that the direction of the polished surface of the mold is consistent with the polishing surface of the polished narrow strip 2, and the mold 1 makes a reciprocating linear motion in the horizontal direction;

[0049] Clamp the polishing narrow belt 2 so that the normal line of the polishing narrow belt 2 is 0-25° to the wide side of the rectangular die hole, and make the deflection of the polishing narrow belt 2 when polishing the lubricating area 19 of the rectangular die hole, polishing the compression area 20 and polishing the size maintaining area 21 The angle is 0°, the upper wire clamp 17 and the lower wire clamp 18 move up and down at the same time to drive the polishing narrow belt 2 to reciprocate up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com