Preparation of 1,1,1-trifluoroethane

A technology of trifluoroethane and anhydrous hydrofluoric acid, applied in halogen substitution preparation, organic chemistry, etc., can solve high production cost, short service life of catalyst, product rate, equipment utilization rate of equipment capacity and low labor efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

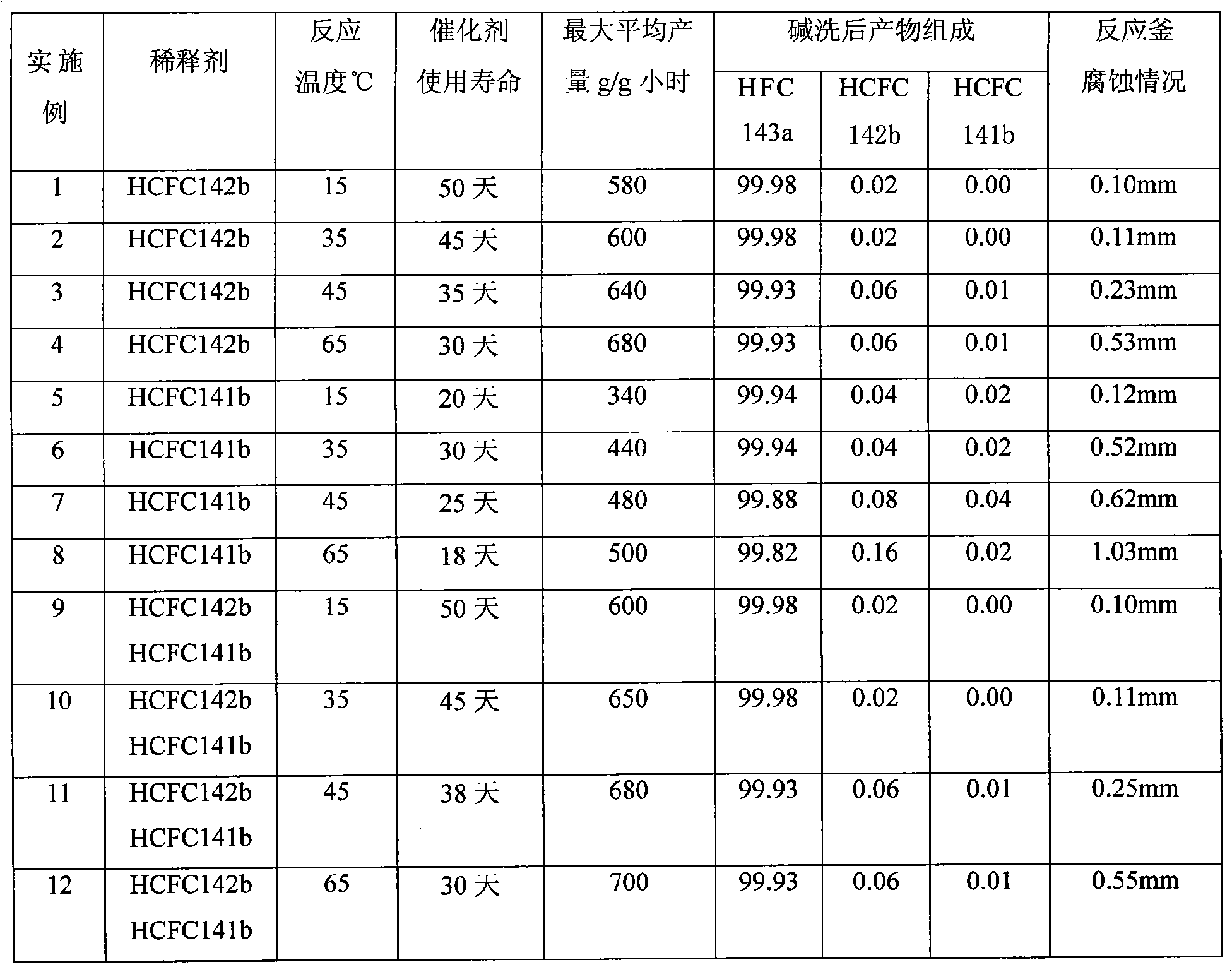

Examples

Embodiment 1

[0008] The reaction kettle is 8 liters, the reactor is made of 16Mn material, the condenser is 0.4 square meters, and the number of reflux trays is 12. First add 3,500 grams of HCFC142b to the reactor, then add 1,000 grams of SbCl5, and heat with hot water to stabilize the temperature of the reactor at 15°C. The jacket of the condenser is fed with frozen brine to maintain the temperature at the top of the condenser at -5°C. HF, HCFC141b, feed according to the ratio. The reaction pressure reaches 1.3 MPa, and the products are released from the condenser at different reaction temperatures.

Embodiment 2

[0010] Control reaction temperature is 35 ℃, other are the same as embodiment one.

Embodiment 3

[0012] Control reaction temperature is 45 ℃, other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com