Phosgene removing method for TDI production

A phosgene and removal technology, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of isocyanic acid derivatives, etc., can solve problems such as waste, unstable vacuum system, increased operational complexity, etc., and achieve improved operation Effects of elasticity, load reduction, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

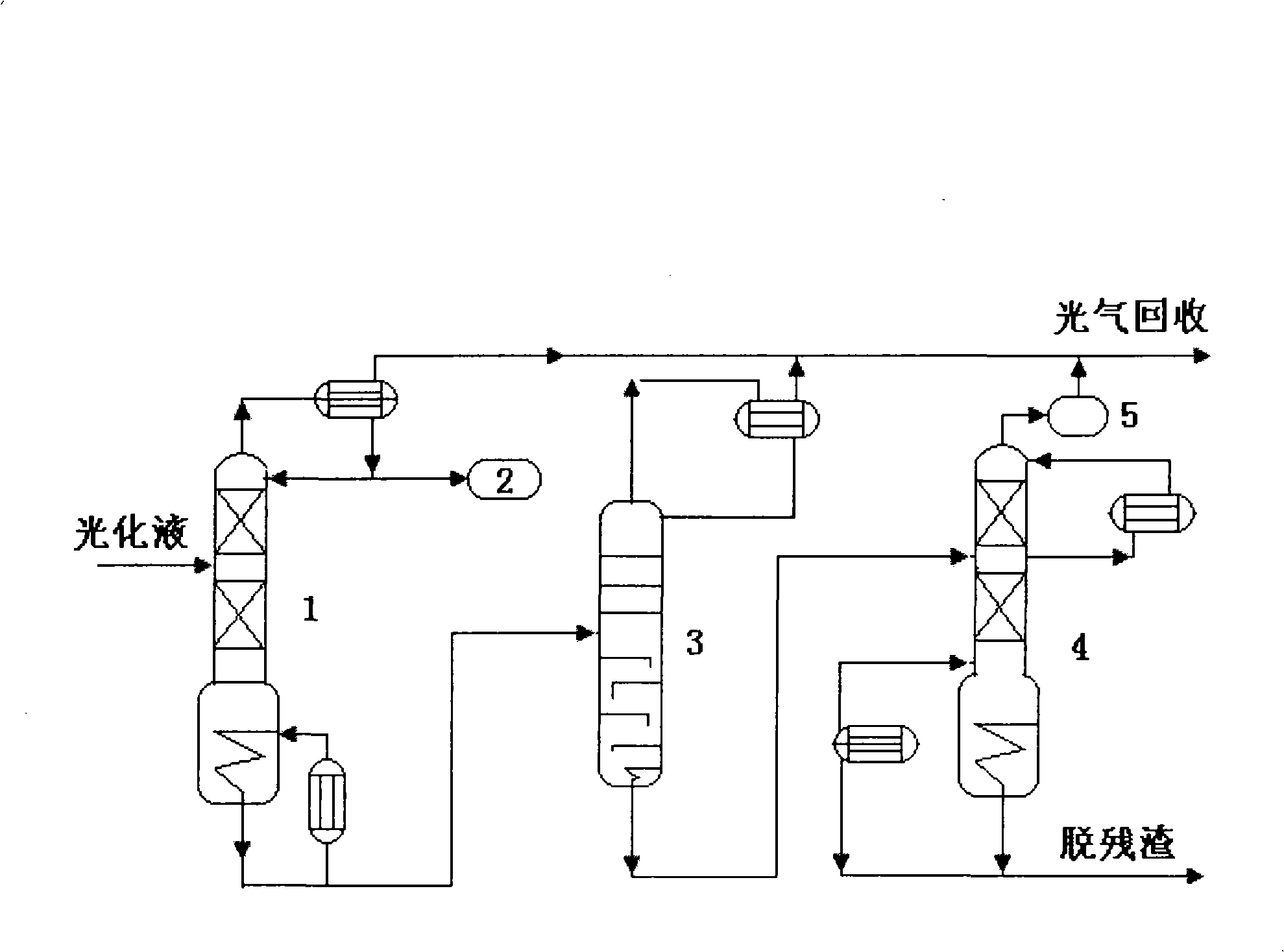

[0010] Such as figure 2 Shown, the present invention is the phosgene removal method that is used for TDI production, by means of a high-pressure de-phosgene tower 1, a phosgene tank 2 communicated with the high-pressure de-phosgene tower 1, a low-pressure de-phosgene tower 3, a negative pressure The dephosgenation tower 4 carries out the removal of phosgene, and its steps are: the reaction solution containing TDI, solvent diethyl isophthalate and excess phosgene from the phosgenation reactor first passes through the high-pressure dephosgenation tower 1 to carry out High pressure dephosphorization treatment, then enter the low pressure dephosphorization tower 3 for low pressure dephosphorization treatment, heat at the bottom of the low pressure dephosphorization tower 3, reboil the phosgene in the low pressure dephosphorization tower 3, then enter the negative pressure dephosphorization tower 4, The phosgene in the material is removed through the negative pressure dephosphoriz...

Embodiment 2

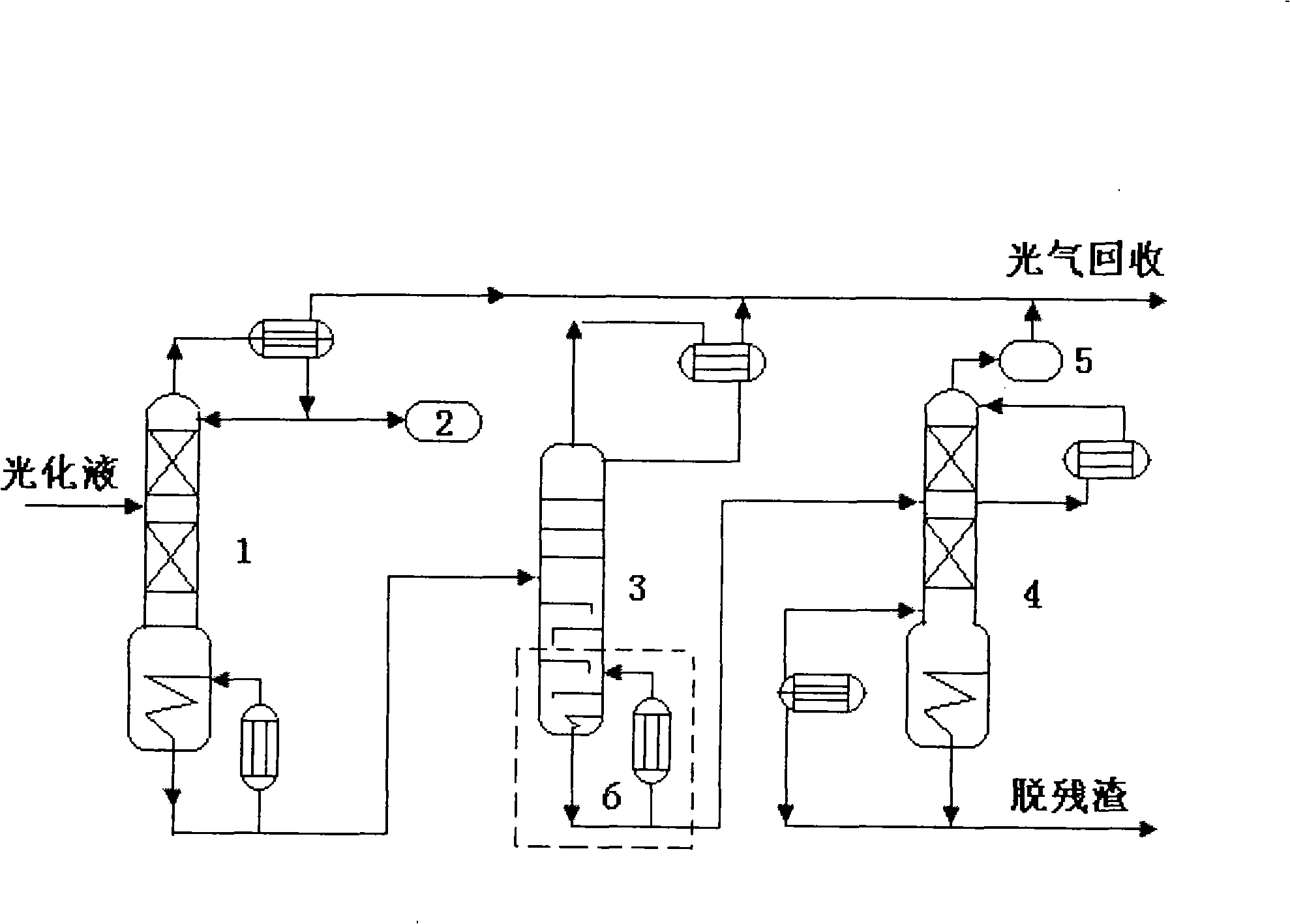

[0012] Such as figure 2 Shown, the present invention is the phosgene removal method that is used for TDI production, and its step is: the reaction solution that contains TDI, solvent diethyl isophthalate and excess phosgene that comes out from phosgenation reactor first passes through The high-pressure dephosphorization tower 1 is processed, and then enters the low-pressure dephosphorization tower 3 equipped with a bottom reboiler 6 for heating, and then enters the negative pressure dephosphorization tower 4, and the phosgene in the material is removed through the negative pressure dephosphorization tower 4 , and then get the final product TDI after going through the residue removal tower and the solvent removal tower. Among them, the high-pressure dephosgene tower 1 removes most of the phosgene, and the removed phosgene is further cooled and directly goes to the phosgene tank 2 for recycling; the phosgene removed by the low-pressure dephosgene tower 3 is sent to the phosgene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com