Three-stage constant temperature biogas production system

A production system and constant temperature technology, which is used in gas production bioreactors, biochemical instruments, biomass post-processing, etc., to achieve stable gas production, comprehensive utilization, and large gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

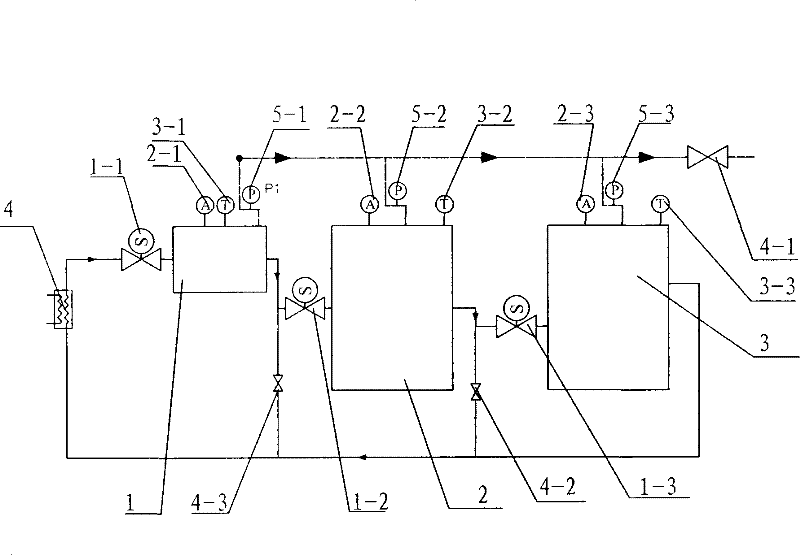

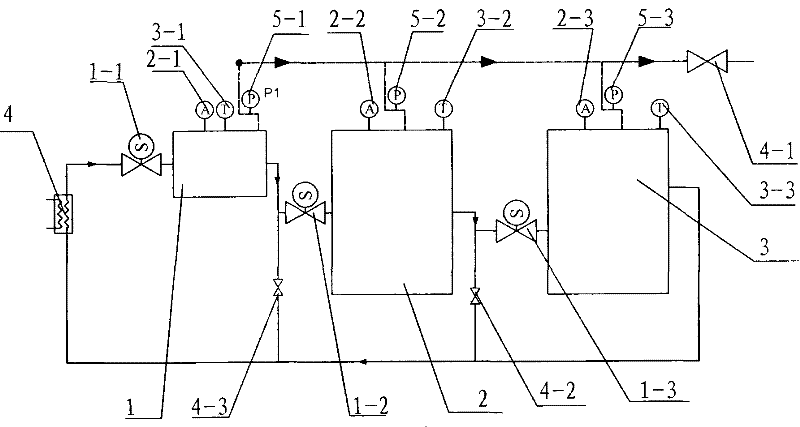

[0018] Such as figure 1 As shown, the three-stage constant temperature biogas production system is characterized in that it includes a high-temperature anaerobic fermenter 1, and the high-temperature anaerobic fermenter 1 is connected with a medium-temperature anaerobic fermenter 2 through a second solenoid valve 1-2. The oxygen fermenter 2 is connected to the normal temperature and constant temperature anaerobic fermenter 3 through the third solenoid valve 1-3, and the high temperature anaerobic fermenter 1 and the medium temperature anaerobic fermenter 2 are respectively passed through the third valve 4-3 and the second valve 4-2 Connected with heat exchanger 4, normal temperature and constant temperature anaerobic fermenter 3 is connected with heat exchanger 4, heat exchanger 4 is connected with high temperature anaerobic fermenter 1 through first electromagnetic valve 1-1, high temperature anaerobic fermenter 1 is equipped with There is a first biogas sampling meter 2-1, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap