Method and structure for preventing explosion-proof submerged sewage pump orifice form generating friction spark and high temperature

A technology for sewage pumps and mouth rings, which is applied to pumps, pump components, non-variable pumps, etc., and can solve problems such as sparks or high temperatures caused by hard friction between moving and static parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

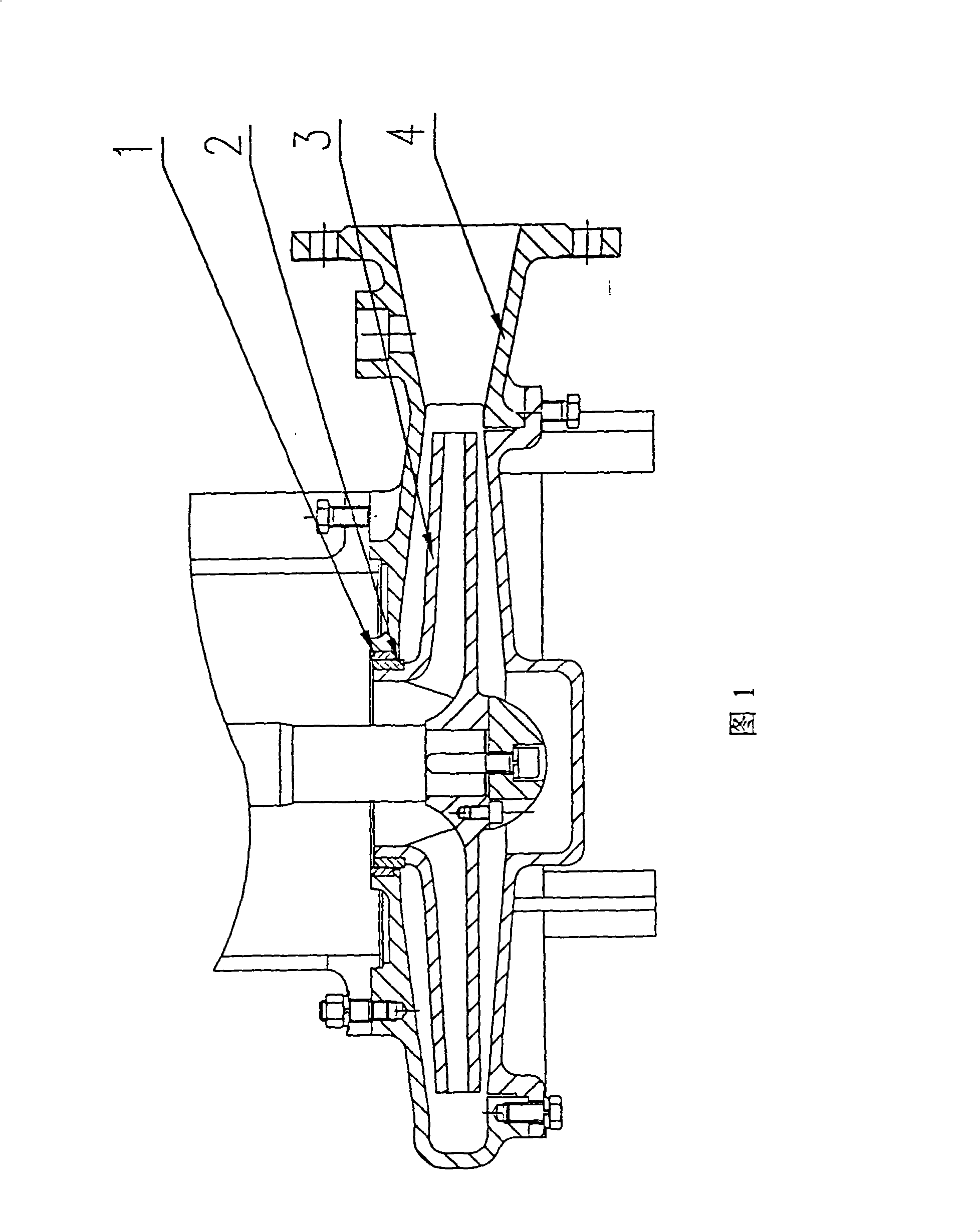

[0009] The method of preventing friction sparks or high temperature at the mouth ring of the explosion-proof submersible sewage pump, first, adopt the method of adding mouth rings to the pump casing and impeller at the same time, the pump casing mouth ring and the impeller mouth ring, the pump casing mouth ring is a static part fixed to the pump casing First, the impeller mouth ring is fixed on the impeller and rotates with the impeller as a moving part. The radial gap between the two mouth rings is 0.15-0.6 mm; second, the impeller and the pump casing are made of high-strength metal materials, and the pump casing The mouth ring no longer uses metal materials, but is the same as the impeller mouth ring, and is made of non-metal materials (materials include polytetrafluoroethylene, imported salon, graphite, and polyurethane).

[0010] Referring to Figure 1, the structure to prevent friction sparks or high temperature at the mouth ring of the explosion-proof submersible sewage pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com