Sensor system and sensor

A sensor and temperature sensor technology, applied in the field of sensor systems, can solve the problems of easy damage, excessive size, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

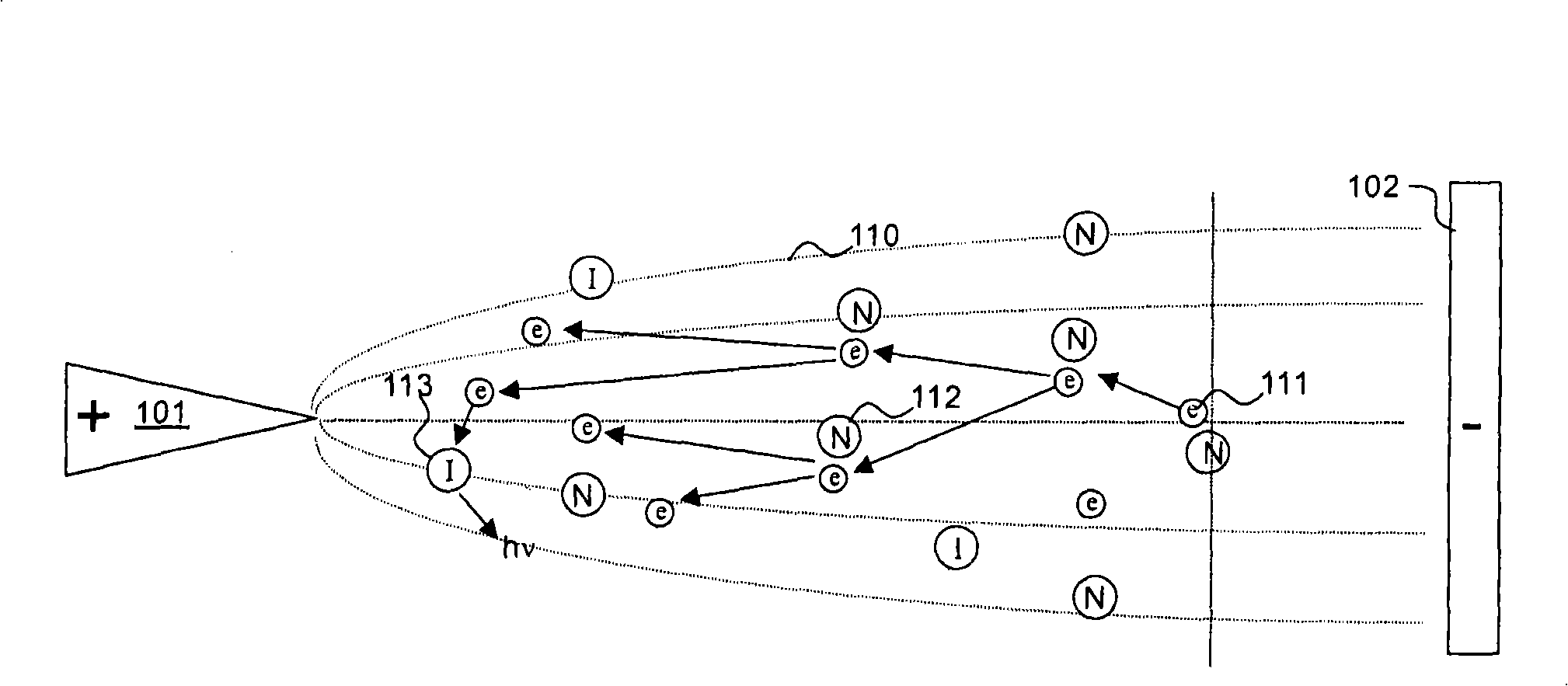

[0030] Before focusing on the sensor system of the present invention, the following reference image 3 , briefly discussing some principle aspects of corona current measurement.

[0031] image 3 is an explanatory sketch showing the principle of corona discharge. A first electrode 101 is arranged at a distance from a second electrode 102 connected to ground potential, the two electrodes together forming a corona gap. In this embodiment, a positive potential of several kV is applied to the electrode, creating an electric field, represented by electric field lines 110 . As a result, free electrons 111 begin to move in the applied electric field, forming an electric current or corona current. As electrons approach the electrode 101, they are accelerated to the point where collisions with neutral molecules 112 will create more free electrons, and so on. This avalanche effect amplifies the corona current.

[0032] The driving force in the above process is the relative differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com