Diphenylamine rubber age inhibitor and preparation thereof

The technology of a rubber antioxidant and diphenylamine, which is applied in the field of diphenylamine rubber antioxidant and its preparation, can solve the problems of easy volatilization and the like, and achieve the effects of reducing volatility, low cost and reducing water extractability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The diphenylamine rubber antioxidant is prepared by the following method:

[0024] 1) Put diphenylamine, styrene and activated clay into the reaction kettle at a ratio of 10:20:1, and react for 4 hours at a speed of 200 rpm and 250°C to obtain A;

[0025] 2) Put diphenylamine, α-methylstyrene and activated clay into the reactor at a ratio of 10:25:1, and react for 8 hours at a speed of 100 revolutions / min and 200°C to generate B;

[0026] 3) Put A, B and ultra-fine calcium carbonate into the reactor in a ratio of 1:2:3, and stir for 1 hour under the conditions of a rotation speed of 100 revolutions / min and 150°C to obtain an antioxidant product.

Embodiment 2

[0028] 1) Put diphenylamine, styrene and activated clay into the reactor at a ratio of 8:22:1, and react for 5 hours at a speed of 500 rpm and 200°C to obtain A;

[0029] 2) Put diphenylamine, α-methylstyrene and activated clay into the reactor at a ratio of 8:30:1, and react for 10 hours at a speed of 300 revolutions / min and 180°C to generate B;

[0030] 3) Put A, B and superfine calcium carbonate into the reaction kettle in a ratio of 1:2:4, and stir for 2 hours under the conditions of a rotation speed of 300 revolutions / min and 140° C. to obtain an antioxidant product.

Embodiment 3

[0032] 1) Put diphenylamine, styrene and activated clay into the reactor at a ratio of 12:18:1, and react for 3 hours at a speed of 100 revolutions / min and 300°C to obtain A;

[0033] 2) Put diphenylamine, α-methylstyrene and activated clay into the reactor at a ratio of 12:20:1, and react for 6 hours at a speed of 50 rpm and 220°C to generate B;

[0034] 3) Put A, B and superfine calcium carbonate into the reaction kettle at a ratio of 1:2:5, and stir for 0.5 hours at a speed of 50 rpm and 160° C. to obtain an antioxidant product.

[0035] Effect example:

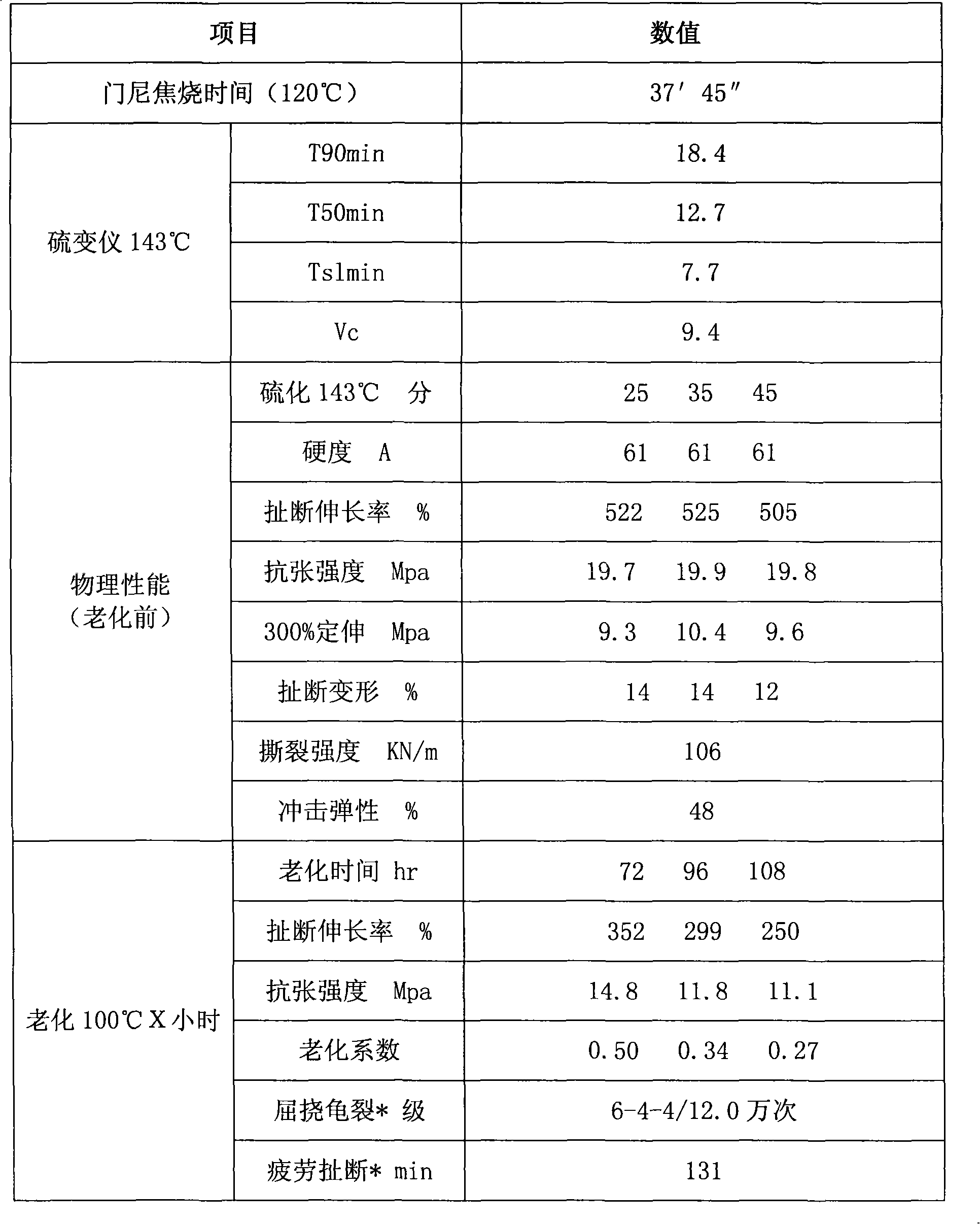

[0036] The antioxidant of Example 1 was used in rubber products.

[0037] The product composition and matching ratio are as follows:

[0038] 65 parts of natural rubber, 35 parts of butadiene rubber, 54 parts of fillers, 0.5 parts of antioxidant 4010NA, 3 parts of antioxidant of Example 1, vulcanization system (sulfur, NOBS, zinc oxide, stearic acid) and 15.3 parts of aromatic oil.

[0039] The physical and mechanical properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com