Chloroprene rubber composition having improved cold tolerance

A chloroprene rubber and composition technology, applied in the field of chloroprene rubber composition, can solve the problems of poor cold resistance, low temperature crystallization, etc., and achieve the effects of improving cold resistance and overcoming low temperature crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

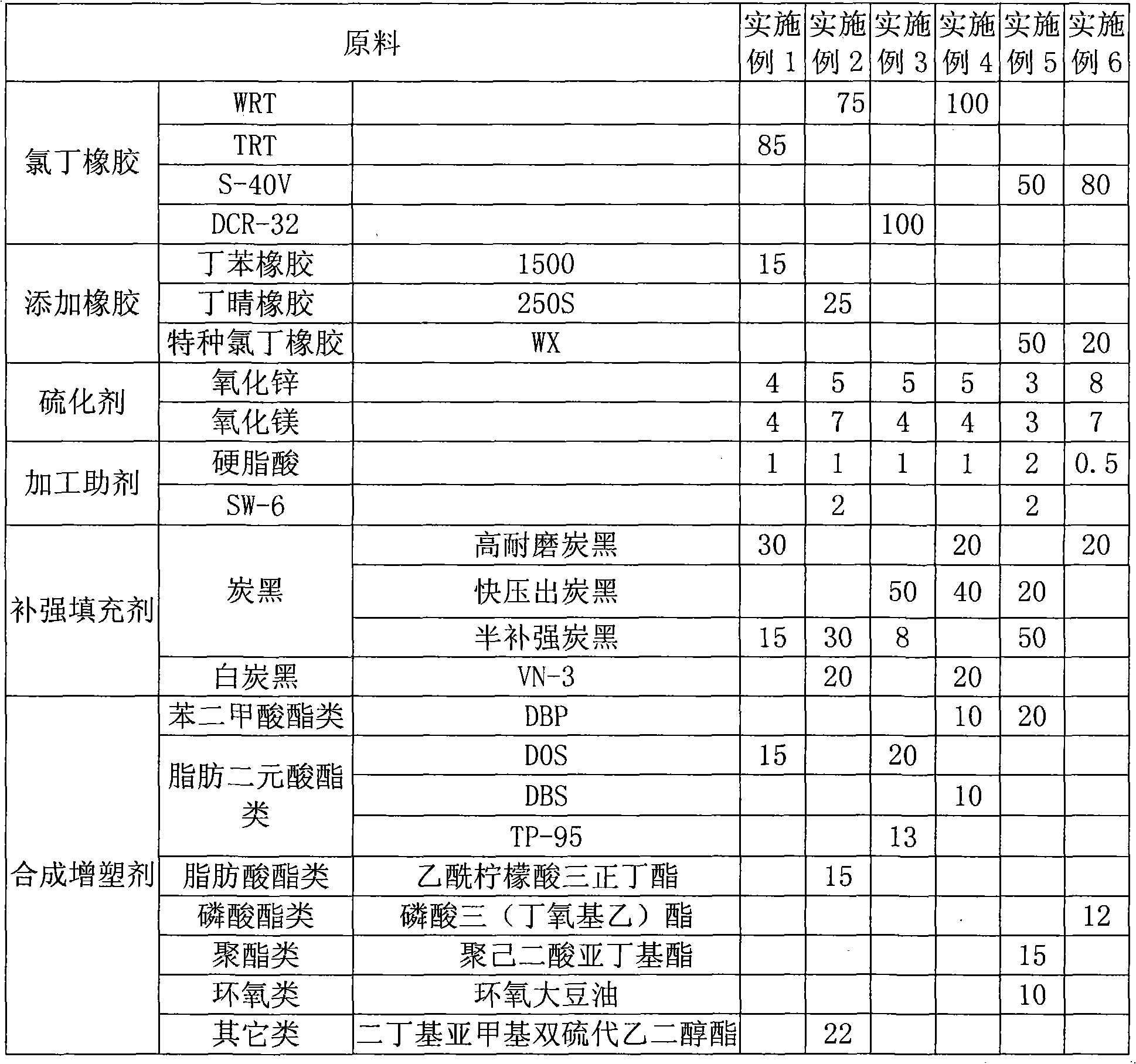

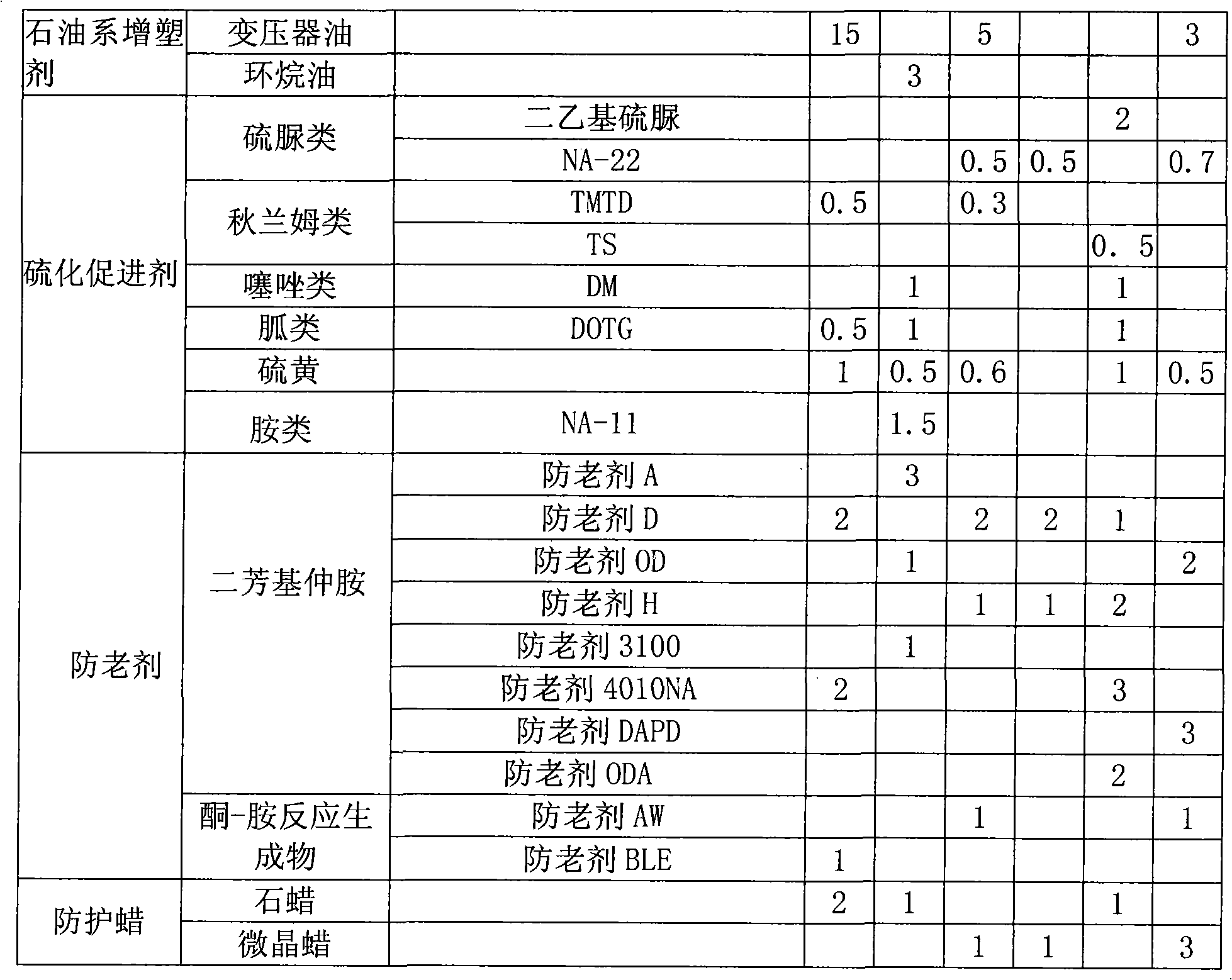

Embodiment 1

[0031] The cold-resistant chloroprene rubber of the present invention is prepared according to the formula described in Table 1 by the conventional method of producing rubber sealing products in the field. The production process steps are as follows:

[0032] Raw rubber mastication

[0033] ↓

[0034] Ingredients→mixing→parking→inspection→distribution (→fabric or metal skeleton coating)→vulcanization→trimming→finished product inspection→in storage.

[0035] Table 1 List of ingredients of the neoprene composition (unit: kg)

[0036]

[0037]

[0038] Table 2 List of manufacturers of raw materials used in the present invention

[0039] raw material name

[0040] DOS

Embodiment 2

[0042] According to the formula shown in Table 1, the cold-resistant neoprene rubber was prepared by the same method as described in Example 1.

Embodiment 3

[0044] According to the formula shown in Table 1, the cold-resistant neoprene rubber was prepared by the same method as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com