Improved method for solving all process defects before leather is pickled and use thereof

A pre-process and leather technology, applied in the improvement field of pigskin process, can solve the problems of non-standardized production and uneven process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

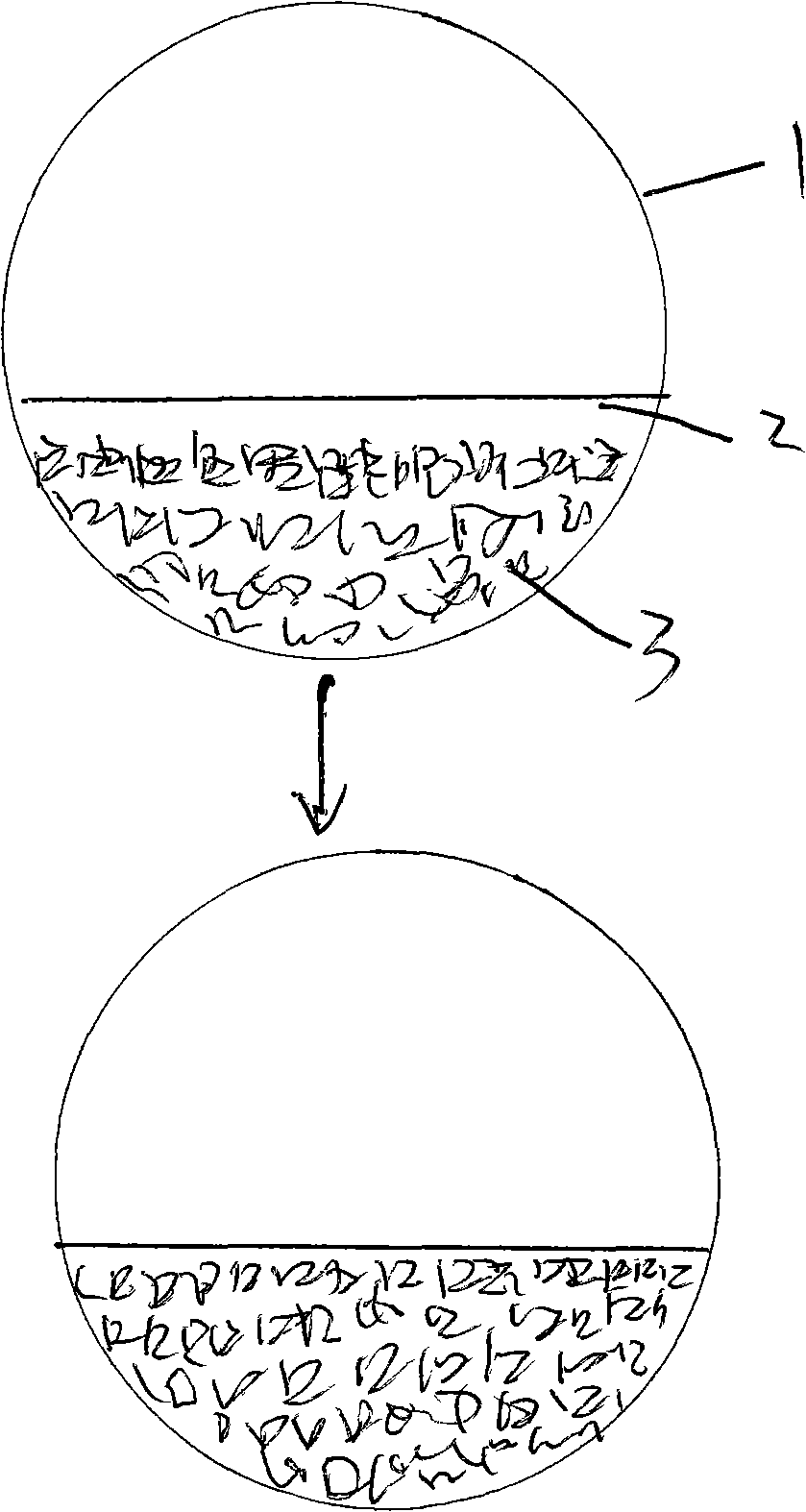

Image

Examples

Embodiment 1

[0014] All domestic materials are used, and the pigskin is washed in drums and stuffy water for 8 minutes, and then washed and soaked in water.

[0015] Rawhide 2400 catties water remaining part

[0016] Water-emulsion type degreasing agent 35 catties weather temperature 25 ℃

[0017] Soda ash 20 catties, water temperature 20 ℃

[0018] Return to the state of fresh skin, the whole skin is soft, no hard core on the buttocks and back, wash with water, expand with alkali, bulge for 170 minutes, then soften for 90 minutes, and then treat according to the usual procedures to solve all technical defects.

Embodiment 2

[0020] Rinse with water for 3 minutes

[0021] Rawhide 2400 catties water remaining part

[0022] Water-emulsion degreaser 37 catties weather temperature 30 ℃

[0023] Soda ash 20 catties, water temperature 20 ℃

[0024] time 2 hours

[0025] Soda liming for 165 minutes, then ditto. Achieve process quality effect.

Embodiment 3

[0027] Rinse with water for 10 minutes

[0028] Rawhide 2400 catties water remaining part

[0029] Water-emulsion type degreasing agent 38 catties weather temperature 20 ℃

[0030] Soda ash 18 catties water temperature 20 ℃

[0031] time 2 hours

[0032] Alkali expansion is 175 minutes, and the process quality effect is the same as above.

[0033] The present invention compares with prior art:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com