A kind of preparation method of injectable self-healing antibacterial hydrogel

A self-healing, hydrogel technology, used in pharmaceutical formulations, prostheses, bandages, etc., can solve the problems of insignificant peeling efficiency, energy consumption, time-consuming, etc., and achieve excellent mechanical strength and biological activity, good biological phase. Capacitive and bioactive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

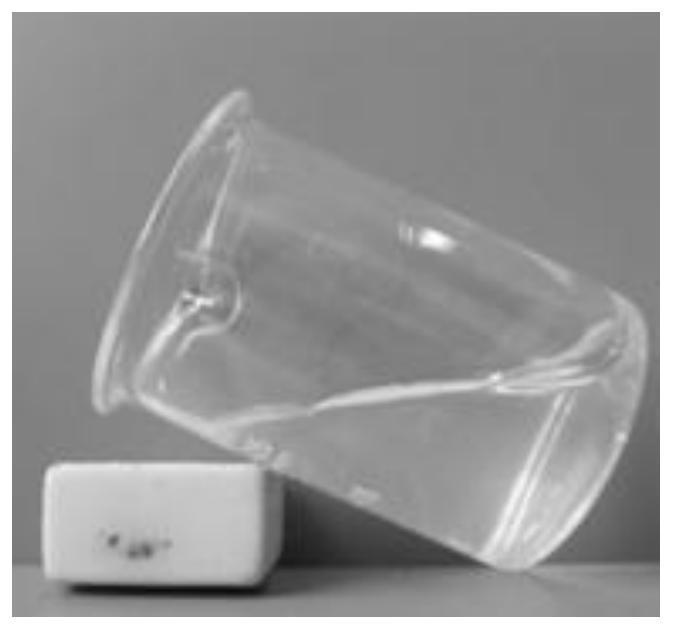

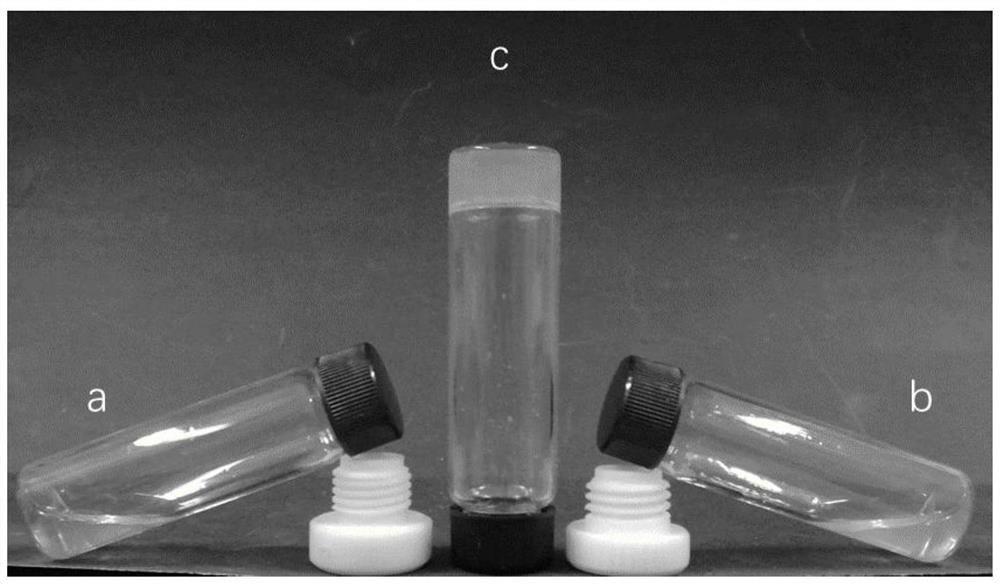

Image

Examples

Embodiment 1

[0023] Prepare 98g of an aqueous solution containing 20wt% potassium hydroxide and 4wt% urea, pre-cool to -30°C, add 2g chitin at room temperature, and mechanically stir for 30 minutes to obtain a transparent and clear 2wt% chitin solution; add to the chitin solution 5.96g of 3-chloro-2-hydroxypropyltrimethylammonium chloride, so that the molar ratio of the quaternization reagent and the chitin unit is 4:1, the reaction temperature is 25 ° C, and HCl is added after stirring for 24 hours to neutralize the reaction The reaction solution was dialyzed with distilled water for 7 days, and then freeze-dried to obtain a white fibrous chitin quaternary ammonium salt sample. The obtained sample was measured for degree of substitution DQ=0.18, NH 2 Content = 15%.

[0024] The preparation methods of Examples 2 to 6 are similar to those of Example 1, and the differences are shown in Table 1 below.

[0025] Table 1 Examples 1-6 preparation parameters and the degree of substitution and NH ...

Embodiment 7

[0028] Prepare 98g of an aqueous solution containing 18wt% potassium hydroxide and 6wt% urea, pre-cool to -30°C, add 2g chitosan at room temperature, and mechanically stir for 30 minutes to obtain a transparent and clear 2wt% chitosan solution; 7.53g of 3-chloro-2-hydroxypropyltrimethylammonium chloride was added to the solution, so that the molar ratio of the quaternization agent and the chitosan unit was 4:1, the reaction temperature was -30 ° C, and after stirring for 24 hours HCl was added to neutralize the reaction solution; the reaction solution was dialyzed with distilled water for 7 days and freeze-dried to obtain a white fibrous chitosan quaternary ammonium salt sample (DQ=0.39, NH 2 = 78%).

[0029] The preparation methods of Examples 8 to 12 are similar to those of Example 7, and the differences are shown in Table 2 below.

[0030]Table 2 Examples 7-12 preparation parameters and the degree of substitution and NH of the obtained quaternary ammonium salt samples 2 c...

Embodiment 13

[0033] Prepare 98g of an aqueous solution containing 20wt% potassium hydroxide and 4wt% urea, pre-cool to -30°C, add 2g chitin at room temperature, and mechanically stir for 30 minutes to obtain a transparent and clear 2wt% chitin solution; add to the chitin solution 3-Chloro-2-hydroxypropyltrimethylammonium chloride, then add chloroacetic acid, so that the molar ratio of quaternization reagent and chitin unit is 4:1, so that the molar ratio of chloroacetic acid and chitin unit is 4 : 1, the reaction temperature was 40 ° C, and HCl was added to neutralize the reaction solution after stirring for 24 hours; the reaction solution was dialyzed with distilled water for 7 days, and freeze-dried to obtain a white fibrous quaternized carboxymethyl chitin sample, and the obtained sample was measured to replace Degree of substitution of quaternary ammonium salt DQ=0.18, degree of carboxymethyl substitution DS=0.15, NH 2 The content is 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com