Sintering method of electronic ceramic

A technology of electronic ceramics and sintering method, applied in the field of electronic ceramics production, can solve the problems of cracking, affecting the intact sintering of the green body, and small shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

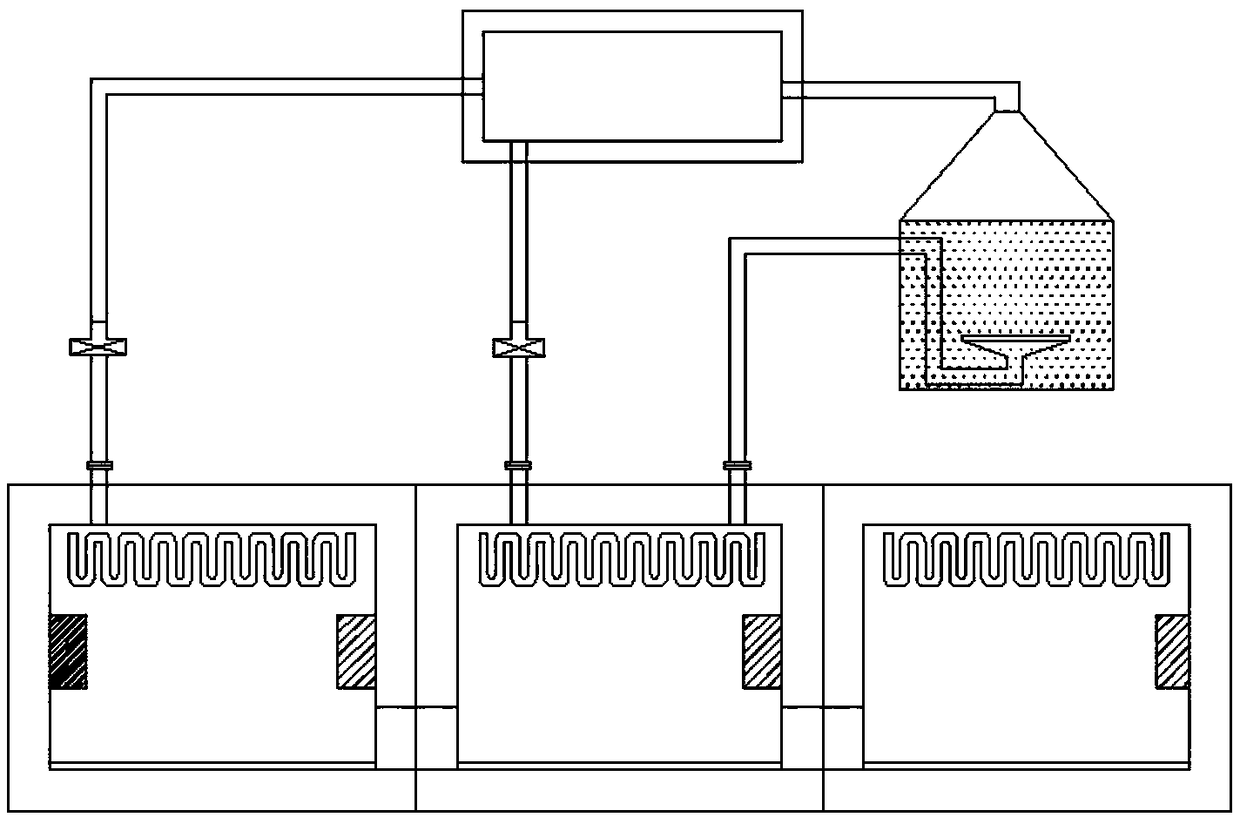

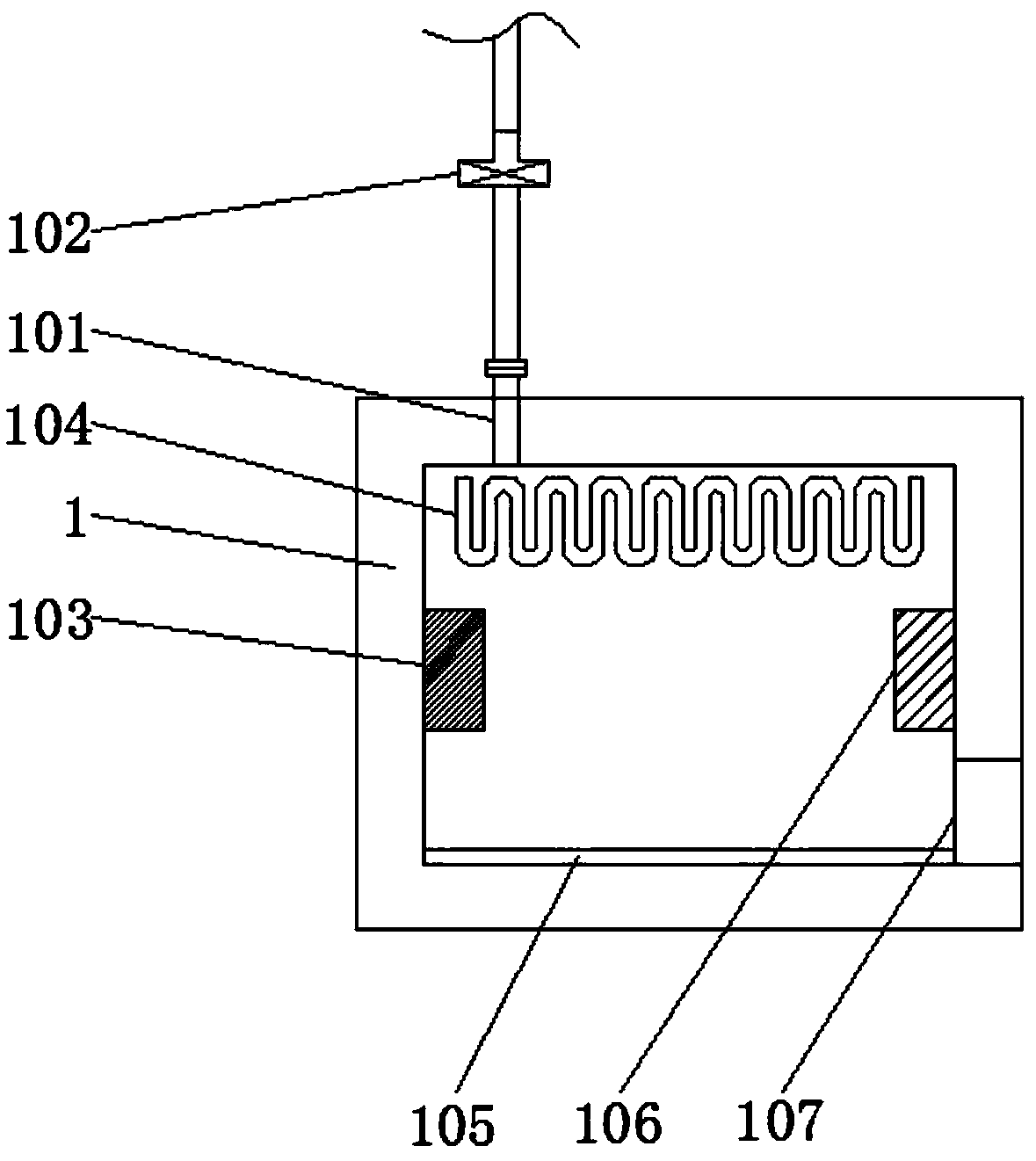

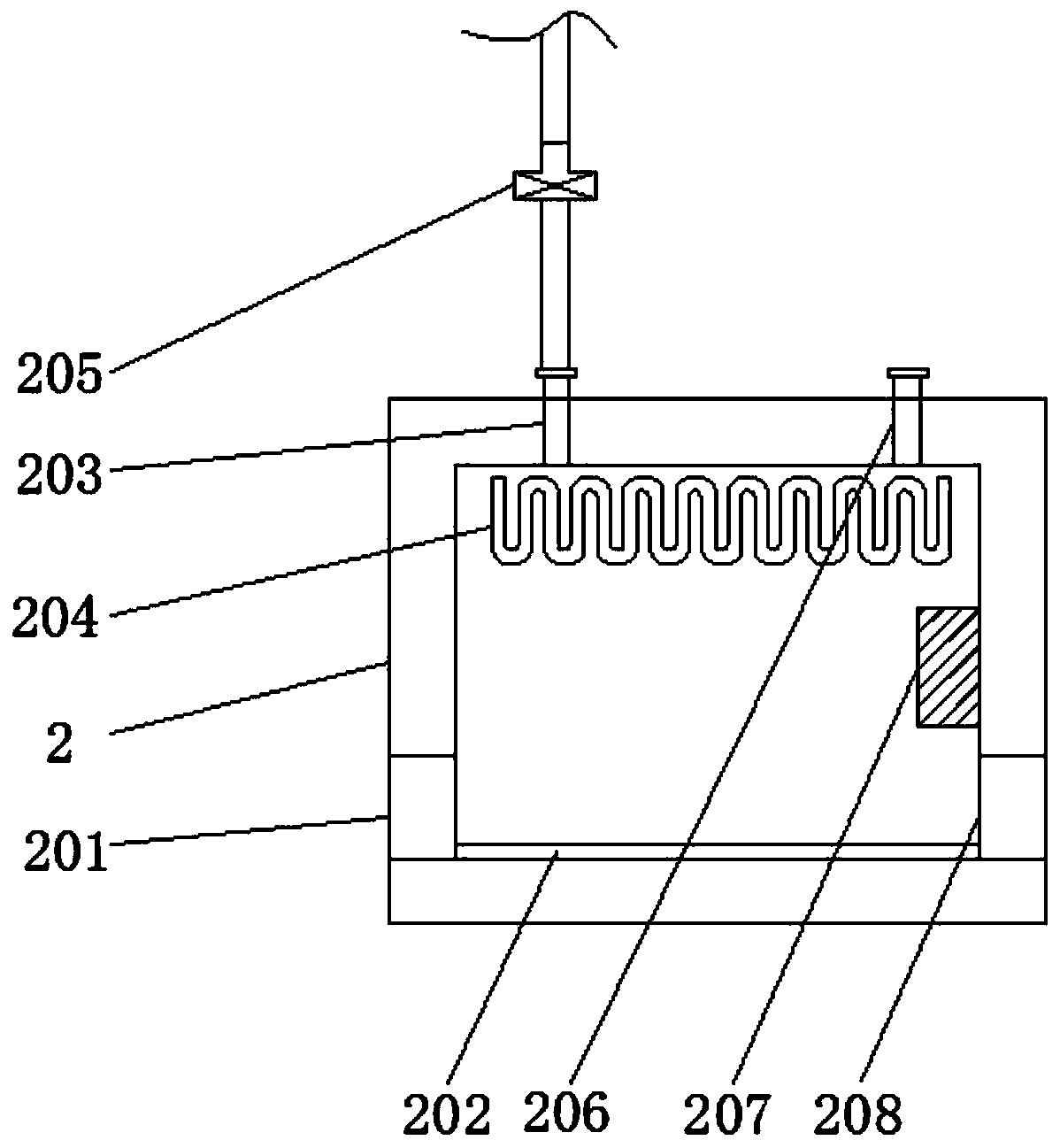

Method used

Image

Examples

Embodiment 1

[0044] The first step: using dry pressing to form a mold, dipping, sanding and drying to obtain a dry electronic ceramic blank to be fired; use the same process to make a sintered gasket;

[0045] The second step: put the first step sintered gasket into the sagger, and place the blank to be sintered on the ceramic sintered gasket;

[0046] The third step: put the sagger obtained in the second step into the freezer, the temperature of the freezer is set at -10 to -5°C, the freezer drops at an average rate of -5°C per hour, and the freezing time is 2 to 3 hours;

[0047] Step 4: Put the sagger obtained in the third step into the high-pressure carbon dioxide preheating chamber to preheat quickly, the transfer time is 5-15 seconds, the preheating temperature is 75-90°C, the air pressure is 0.5-1MPa, and the preheating time is 10-10 30 minutes;

[0048] Step 5: Put the sagger obtained in Step 4 into a carbon dioxide heating furnace, heat it to 700-900°C at a rate of 100-300°C per ...

Embodiment 2

[0051] The first step: using dry pressing to form a mold, dipping, sanding and drying to obtain a dry electronic ceramic blank to be fired; use the same process to make a sintered gasket;

[0052] The second step: put the first step sintered gasket into the sagger, and place the blank to be sintered on the ceramic sintered gasket;

[0053] The third step: Put the sagger obtained in the second step into the freezer, the temperature of the freezer is set at -10 ~ ℃, the freezer drops at an average rate of -5°C per hour, and the freezing time is 2 hours;

[0054] Step 4: Put the sagger obtained in the third step into the high-pressure carbon dioxide preheating chamber to preheat quickly, the transfer time is 15 seconds, the preheating temperature is 75°C, the air pressure is 1MPa, and the preheating time is 20 minutes;

[0055] Step 5: Put the sagger obtained in Step 4 into a carbon dioxide heating furnace, heat it up to 900°C at a rate of 200°C per hour, and keep it warm for 1 t...

Embodiment 3

[0058] The first step: using dry pressing to form a mold, dipping, sanding and drying to obtain a dry electronic ceramic blank to be fired; use the same process to make a sintered gasket;

[0059] The second step: put the first step sintered gasket into the sagger, and place the blank to be sintered on the ceramic sintered gasket;

[0060] The third step: put the sagger obtained in the second step into the freezer, the temperature of the freezer is set to -5°C, the freezer drops at an average rate of -5°C per hour, and the freezer time is 3 hours;

[0061] Step 4: Put the sagger obtained in the third step into the high-pressure carbon dioxide preheating chamber to preheat quickly, the transfer time is 15 seconds, the preheating temperature is 90°C, the air pressure is 0.5MPa, and the preheating time is 30 minutes;

[0062] Step 5: Put the sagger obtained in Step 4 into a carbon dioxide heating furnace, heat it to 900°C at a rate of 300°C per hour, and keep it warm for 1 hour; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com