Encapsulation structure of micro-nano bionic vector water sound sensor

An underwater acoustic sensor and vector technology, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of microstructures that cannot be tested and affected, and achieve the effect of perfecting and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

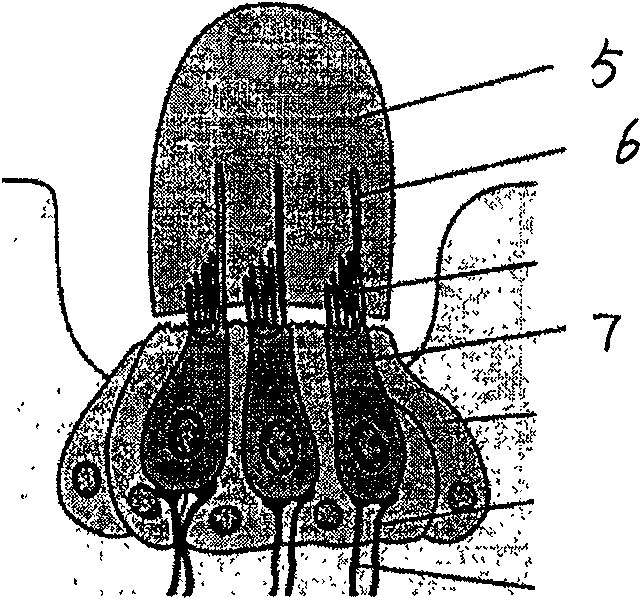

[0027] Such as Figure 8 , 10 As shown, the packaging structure of the micro-nano bionic vector underwater acoustic sensor includes a support for fixing the micro-nano bionic vector underwater acoustic sensor, a packaging shell that is covered outside the micro-nano bionic vector underwater acoustic sensor and is sealed and fixed with the support. The encapsulation shell is filled with an insulating liquid with a density close to that of water, and the encapsulation shell is a sound-permeable rubber cap 14 made of polyurethane encapsulation material with high frequency, low attenuation and low water permeability through an acoustic encapsulation process. The insulating liquid adopts castor oil 15; the support body is divided into an external support body, an internal support body 16 made of insulating material for directly fixing the micro-nano bionic vector underwater acoustic sensor, and the external support body is divided into a fixed support body 17. Connect the fixed le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com