Method for obtaining human body defect skelecton titanium alloy restoring body by mould stamping

A prosthetic and titanium alloy technology, applied in simulators, instruments, computer control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better understand the technical solutions of the present invention, further description is given below through the accompanying drawings and specific embodiments.

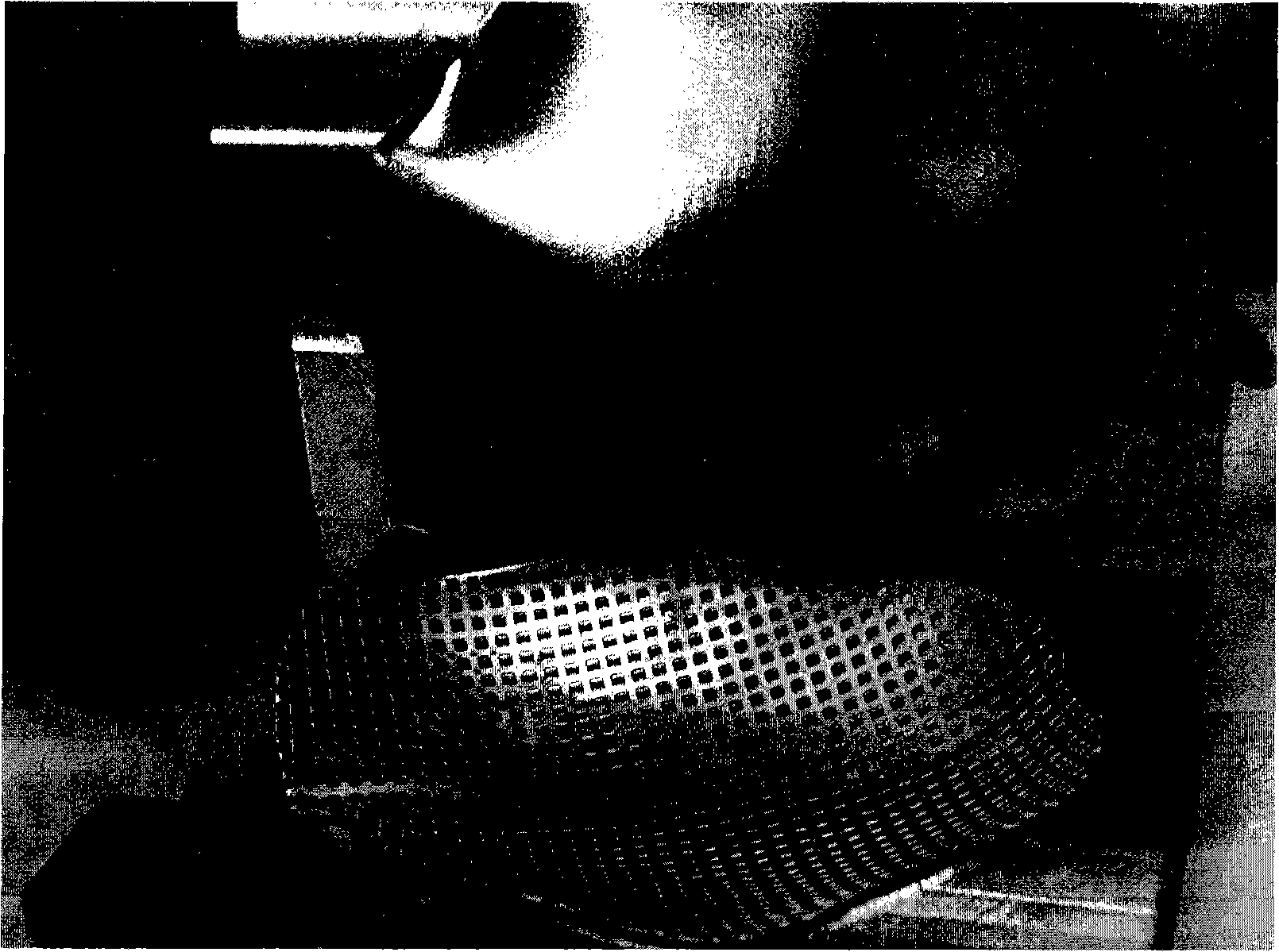

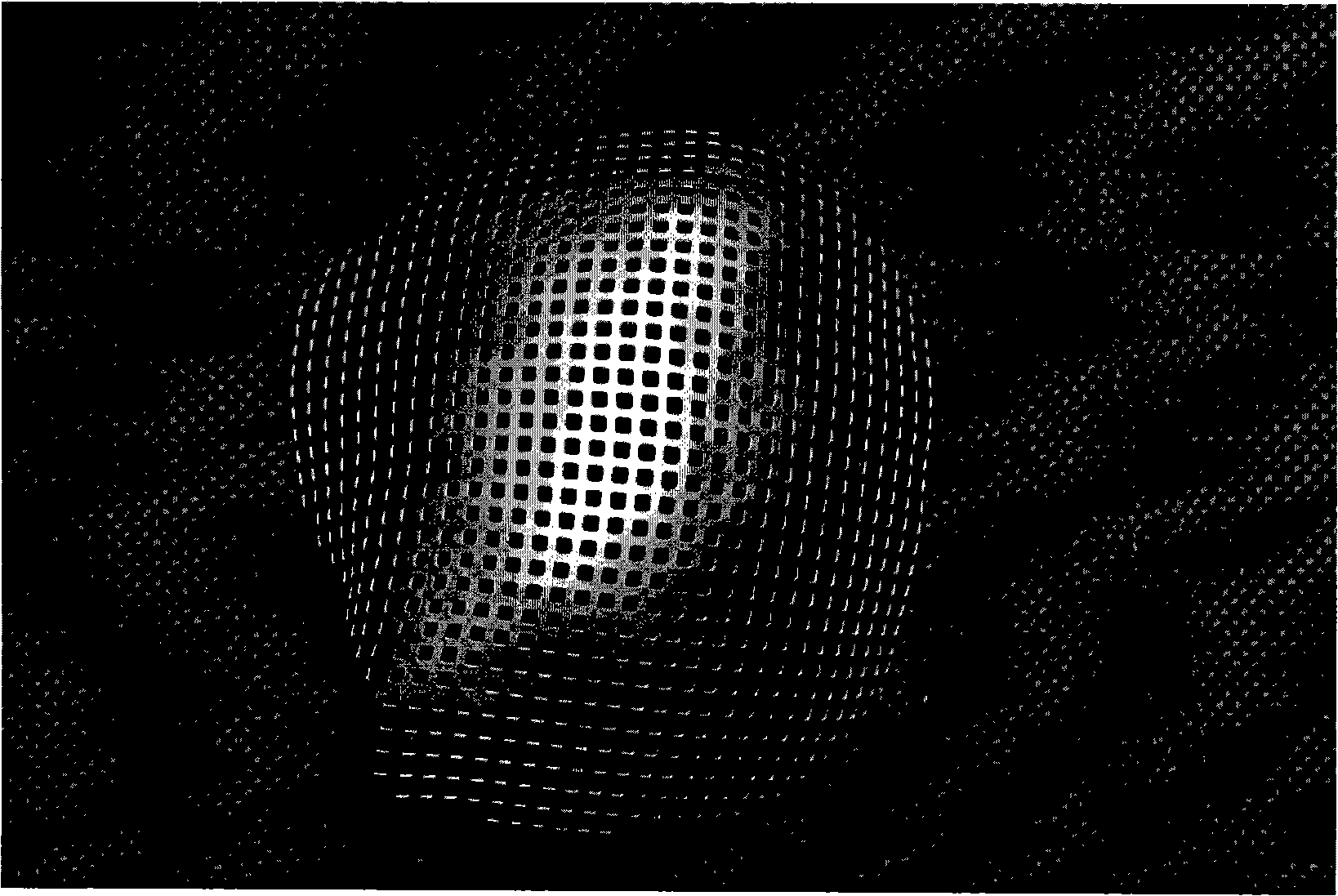

[0062] The patient's skull is damaged, and the damage is large-scale damage. The trauma area is about 120mm × 120mm. According to the invention of this method, the skull defect is repaired. The process is as follows:

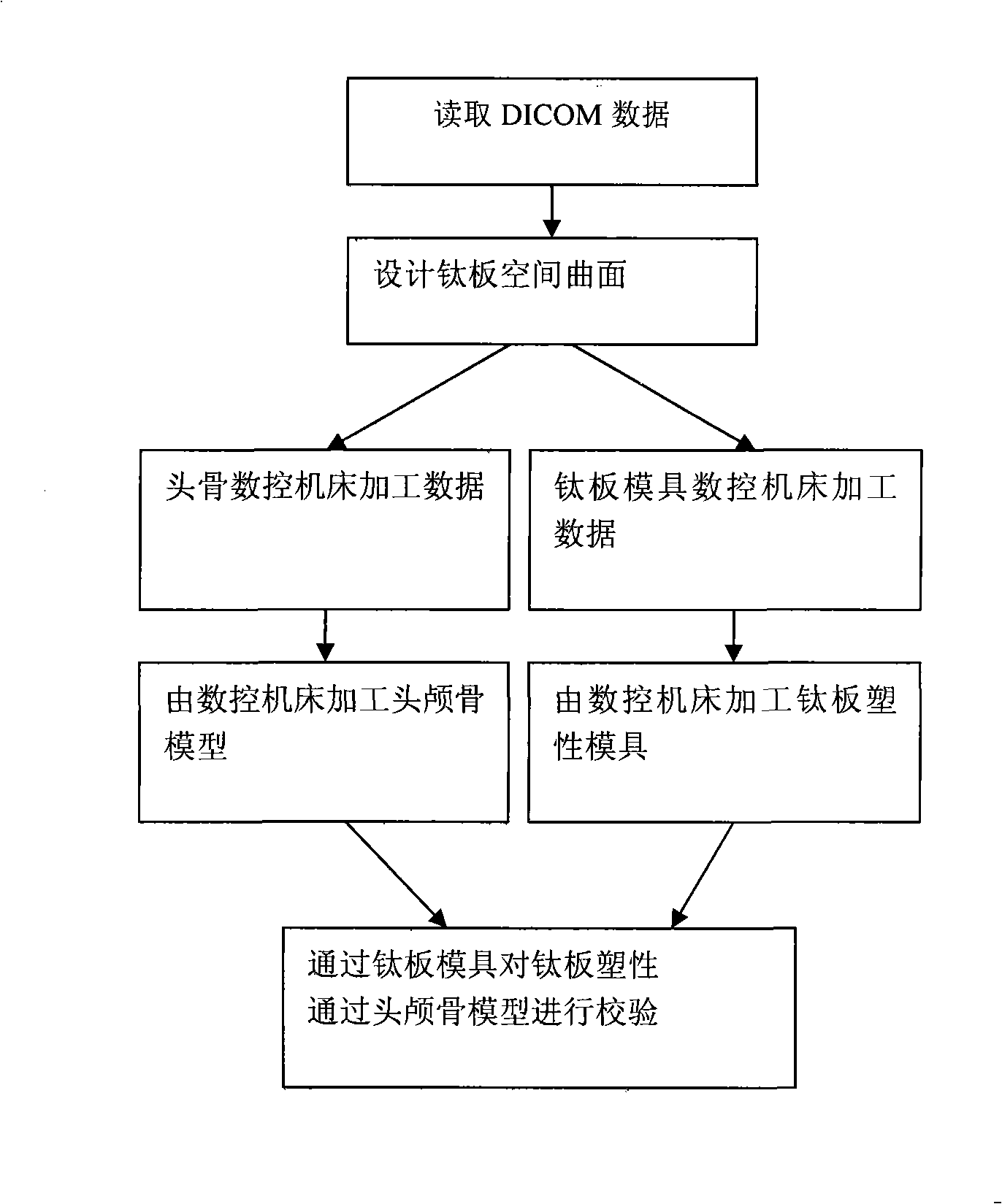

[0063] 1. The computer reads the DICOM format data of CT or MR of the patient's bones;

[0064] 2. The DICOM data of the patient's bone image is reconstructed in the coronal, sagittal and axial positions. Generate three phase profiles of the patient's skeleton. On the axial view of the patient's bone and referring to the coronal and sagittal views, a bezier curve for forming the titanium plate covering the bone defect of the patient was designed.

[0065] First, 11 control points are obtained at the defect in the first frame. Since the human body is basically symmetrical, these 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com