Control tool

A jig and pressing device technology, applied in the direction of electrical components, support structure installation, installation board safety device, etc., can solve the problems that affect the overall performance of the sliding cover mechanism, long time, and the FPC module attachment position is not in place, etc. Achieve the effects of avoiding improper attachment position, improving overall performance, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

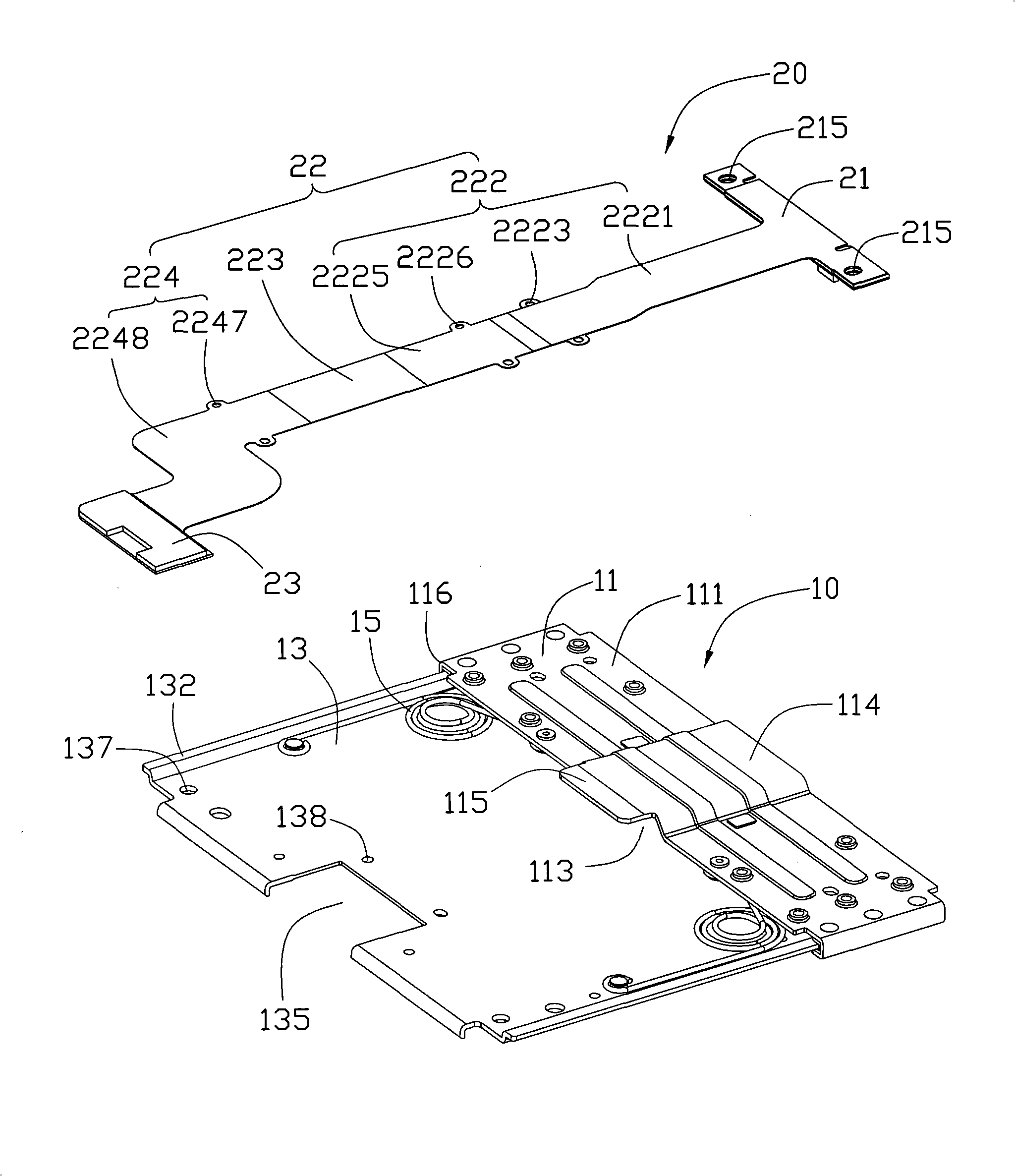

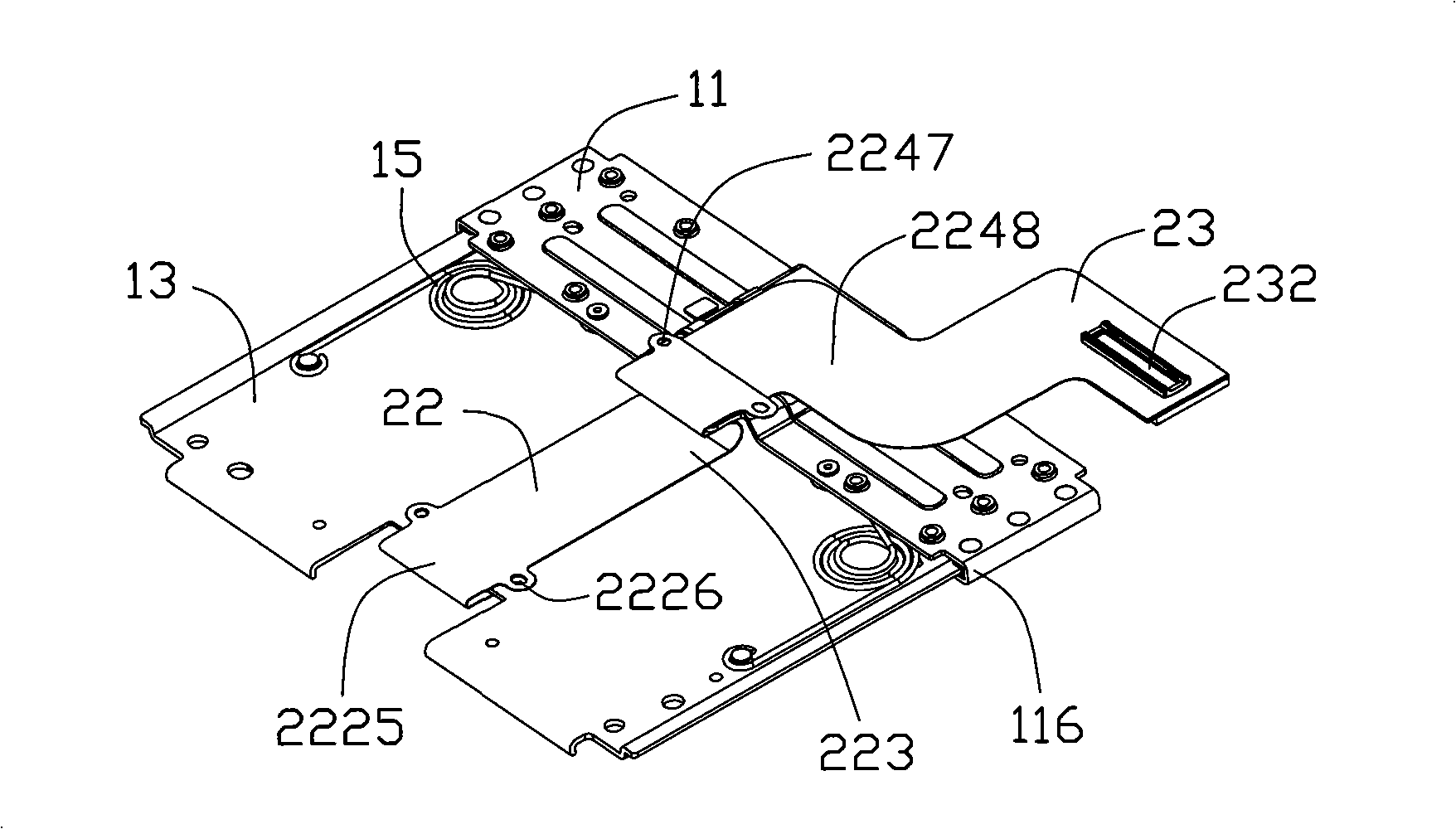

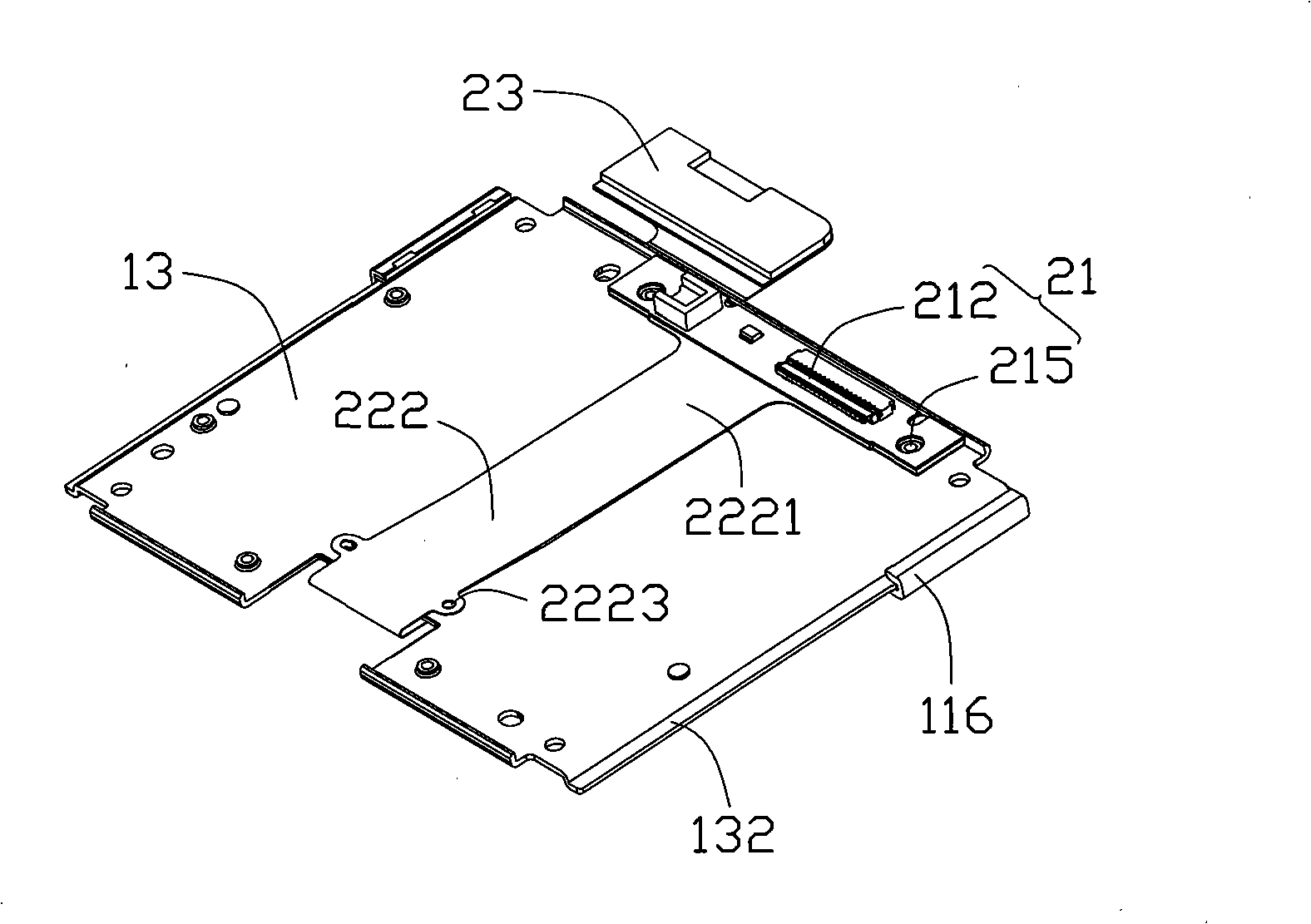

[0023] see figure 1 , is a three-dimensional schematic diagram of a flexible printed circuit module 20 (flexible printed circuit module 20 , hereinafter referred to as FPC module 20 ) and a slider mechanism 10 of the slide-type portable electronic device to be assembled. The sliding cover mechanism 10 includes a fixing part 11 , a sliding part 13 and two restoring mechanisms 15 . The sliding member 13 is slidably mounted on the fixing member 11 so that the sliding member 13 can move back and forth along the path defined by the fixing member 11 , and can automatically return to an initial position driven by the restoring mechanism 15 . The fixing member 11 is substantially in the shape of a straight thin plate, and includes a first surface 111 and a second surface (not shown) substantially parallel to the first surface 111 . A portion of the second surface of the middle section of the fixing member 11 is recessed toward the first surface 111 , thereby forming an accommodating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com