Spiral type lunar roving vehicle wheel

A lunar rover and spiral technology, which is applied in the directions of wheels, extraterrestrial vehicles, and vehicle components, can solve the problems of the lunar rover not working properly, the lunar wheel being uncomfortable climbing, and the lunar wheel being trapped in the lunar soil. Idling, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

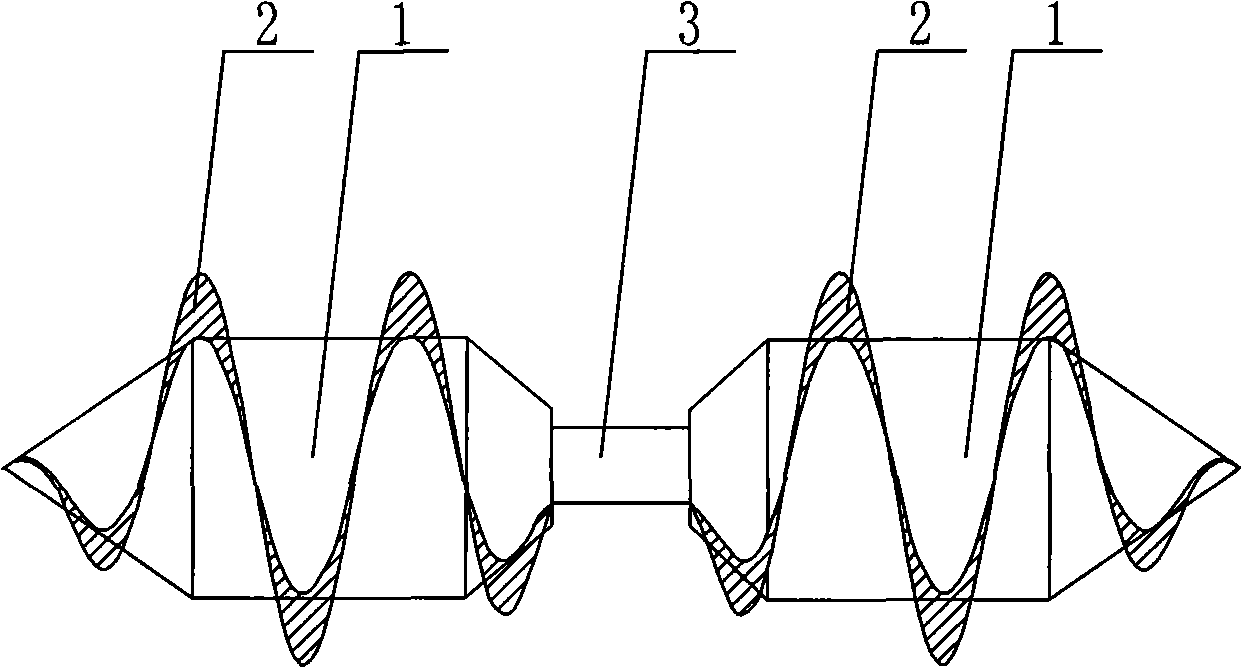

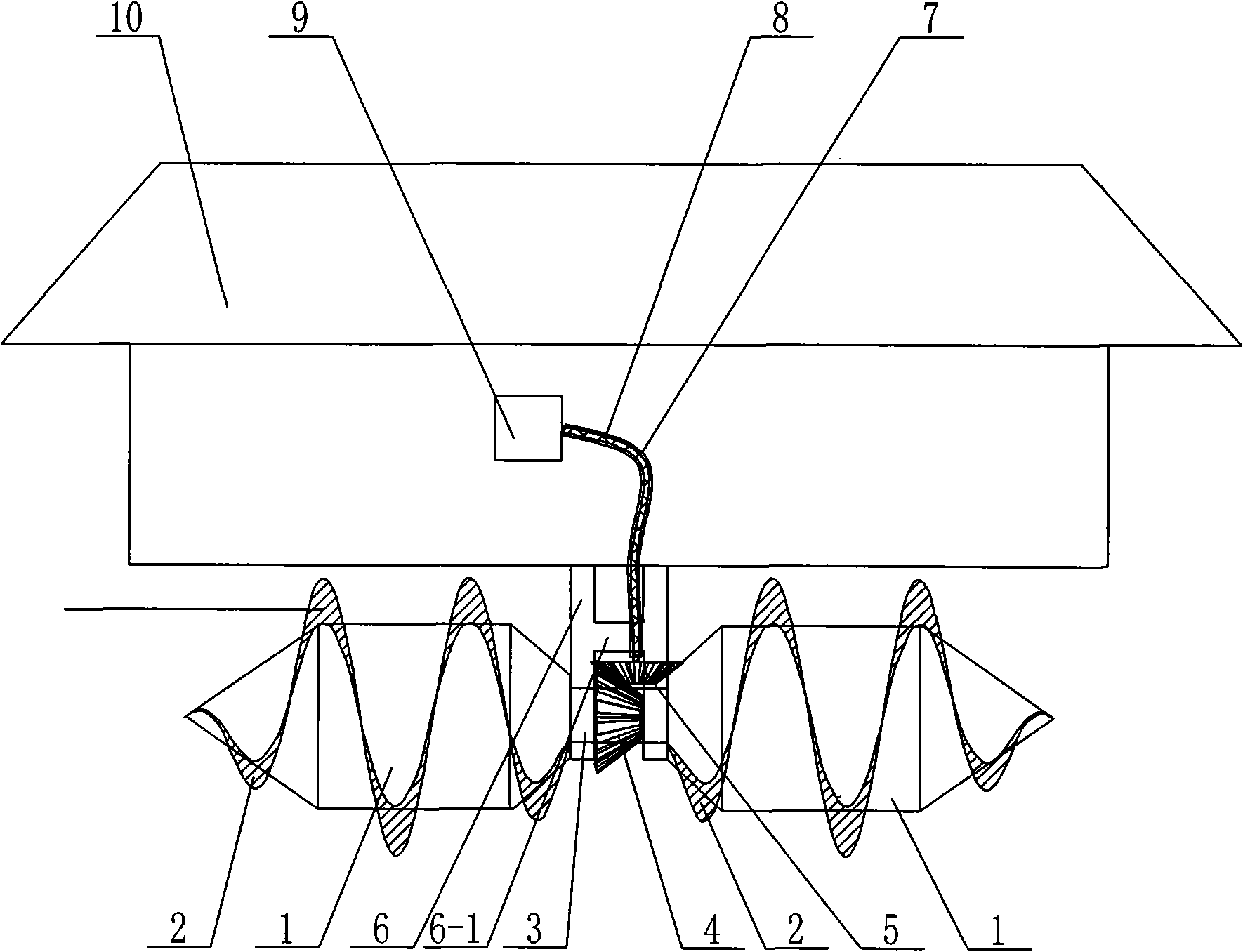

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment consists of two wheel bodies 1, a wheel shaft 3, two helical blades 2, a driven bevel gear shaft 4, a driving bevel gear shaft 5, a fixed frame 6, a soft casing 7, and a drive cable 8 , a motor 9 and a car body 10, the two wheel bodies 1 are symmetrically fixed on both ends of the wheel shaft 3, and the outer walls of the two wheel bodies 1 are respectively provided with a helical blade 2 along the axial direction. The driven bevel gear shaft 4 is installed on the wheel shaft 3, the driving bevel gear shaft 5 is installed on the beam 6-1 of the fixed frame 6, the driving bevel gear shaft 5 is meshed with the driven bevel gear shaft 4, and the wheel shaft 3 is connected to the car body 10 through the fixing frame 6, the motor 9 is arranged in the car body 10, one end of the driving cable 8 is connected to the driving bevel gear shaft 5, and the other end of the dri...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the two ends of the two wheel bodies 1 in this embodiment away from the wheel shaft 3 are tapered, and the two ends of the two wheel bodies 1 close to the wheel shaft 3 are in the shape of a truncated cone. Set it up to keep moving with less resistance and faster speeds. Other compositions and connections are the same as in the first embodiment.

[0009] working principle:

[0010] Such as figure 2 As shown, the motor 9 works and rotates, driving the driving cable 8 connected thereto to rotate, the driving cable 8 and the driving bevel gear shaft 5 are connected as one, and the driving bevel gear shaft 5 drives the driven bevel gear shaft 4 to rotate, from The bevel gear shaft 4 is integrated with the wheel body 1 and the wheel shaft 3, so the motor 9 drives the wheel body 1 to rotate. Since the soft casing 7 and the driving cable 8 are flexible structures with a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com