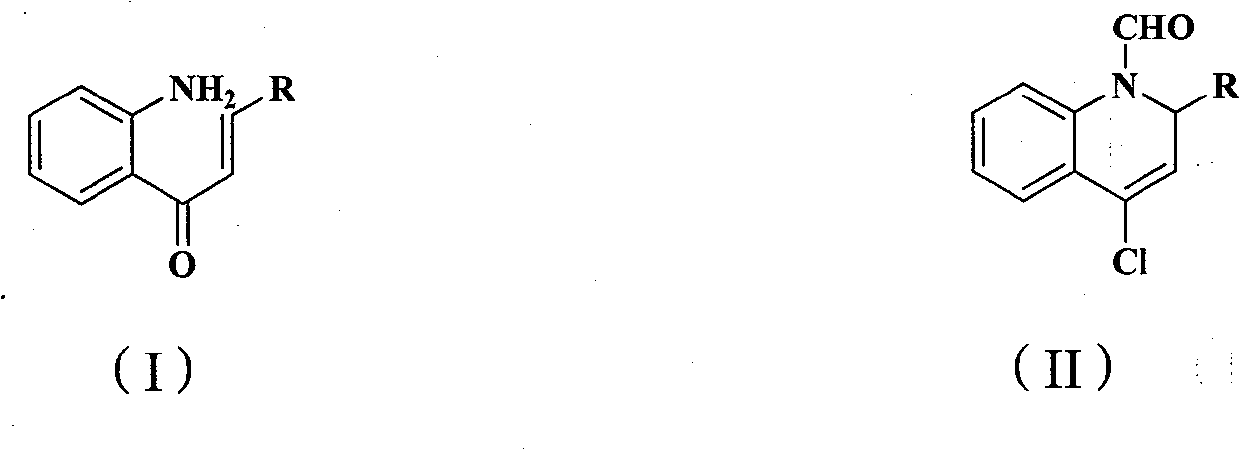

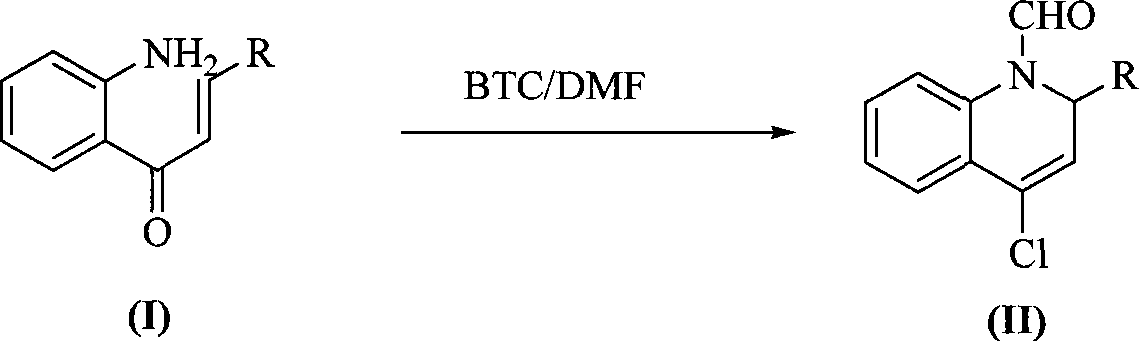

Method for preparing N- formyl-2H-4chloroquinoline derivate

A -2H-4-, formyl technology, applied in the field of preparation of N-formyl-2H-4-chloroquinoline derivatives, can solve the problems of unsatisfactory yield, many side reactions, unfriendly environment and the like, and achieves The effect of simple operation, improved reaction yield, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1N-formyl-4-chloro-2-phenyl-2H-quinoline

[0024] Add 0.66g N,N-dimethylformamide into a 50mL three-necked reaction flask equipped with a magnetic stirrer, a drying tube, a thermometer, and a dropping funnel, stir in an ice-water bath and cool down to 0-5°C, then add bis(tri Chloromethyl)carbonate solution (0.891g, 3mmol, dissolved in 3mL toluene), reacted at 0~5℃ for 45min after dropping, and then added dropwise at 0~5℃ containing 1-(2-aminobenzene)- The toluene solution of 3-phenylchalcone (0.224g, 1mmol, dissolved in 3mL toluene) was reacted at 0-5°C for 1 hour after dropping, and then heated to 90°C for 3 hours. The progress of the reaction was tracked by TLC. After the reaction, the reaction product was separated and purified: the above reaction mixture was poured into 15 g of crushed ice, and the pH value was adjusted to about 8 with 10% NaOH solution, and then stirred for 0.5 h to complete hydrolysis, then the organic layer was separ...

Embodiment 2

[0026] The preparation of embodiment 2N-formyl-4-chloro-2-phenyl-2H-quinoline

[0027] Add 0.54g N,N-dimethylformamide into a 50mL three-necked reaction flask equipped with a magnetic stirrer, a drying tube, a thermometer, and a dropping funnel, stir in an ice-water bath and cool down to 0-5°C, then dropwise add bis(tri Chloromethyl)carbonate solution (0.594g, 2mmol, dissolved in 2mL toluene), reacted at 0-5°C for 45min after dropping, then added dropwise at 0-5°C containing 1-(2-aminobenzene)- The toluene solution of 3-phenylchalcone (0.224g, 1mmol, dissolved in 3mL toluene) was reacted at 0-5°C for 2 hours after dropping, then heated to 90°C for 3 hours, followed by TLC. Aftertreatment is the same as in Example 1, and the yield is 56%. Physical property data is with embodiment 1.

Embodiment 3

[0028] The preparation of embodiment 3N-formyl-4-chloro-2-phenyl-2H-quinoline

[0029]Add 2.2g of N,N-dimethylformamide and 8mL of toluene into a 50mL three-necked reaction flask equipped with magnetic stirring, drying tube, thermometer, and dropping funnel, stir in an ice-water bath to cool down to 0-5°C, and then add dropwise Bis(trichloromethyl)carbonate solution (2.97g, 10mmol, dissolved in 6mL toluene), reacted at 0-5°C for 45min after dropping, then added dropwise at 0-5°C containing 1-(2-amino Benzene)-3-phenylchalcone toluene solution (0.224g, 1mmol, dissolved in 2mL toluene), reacted at 0-5°C for 2 hours after dropping, then raised the temperature to 90°C for 3 hours, followed by TLC schedule. Aftertreatment is the same as in Example 1, and the yield is 86%. Physical property data is with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap