Safety conveying method for phosphorus oxychloride

A kind of phosphorus oxychloride and safe technology, applied in the field of safe transportation of phosphorus oxychloride, can solve the problems of on-site operator troubles, frequent replacement of source bottles, etc., to eliminate potential safety hazards, eliminate manual replacement of quartz containers, and facilitate logistics operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

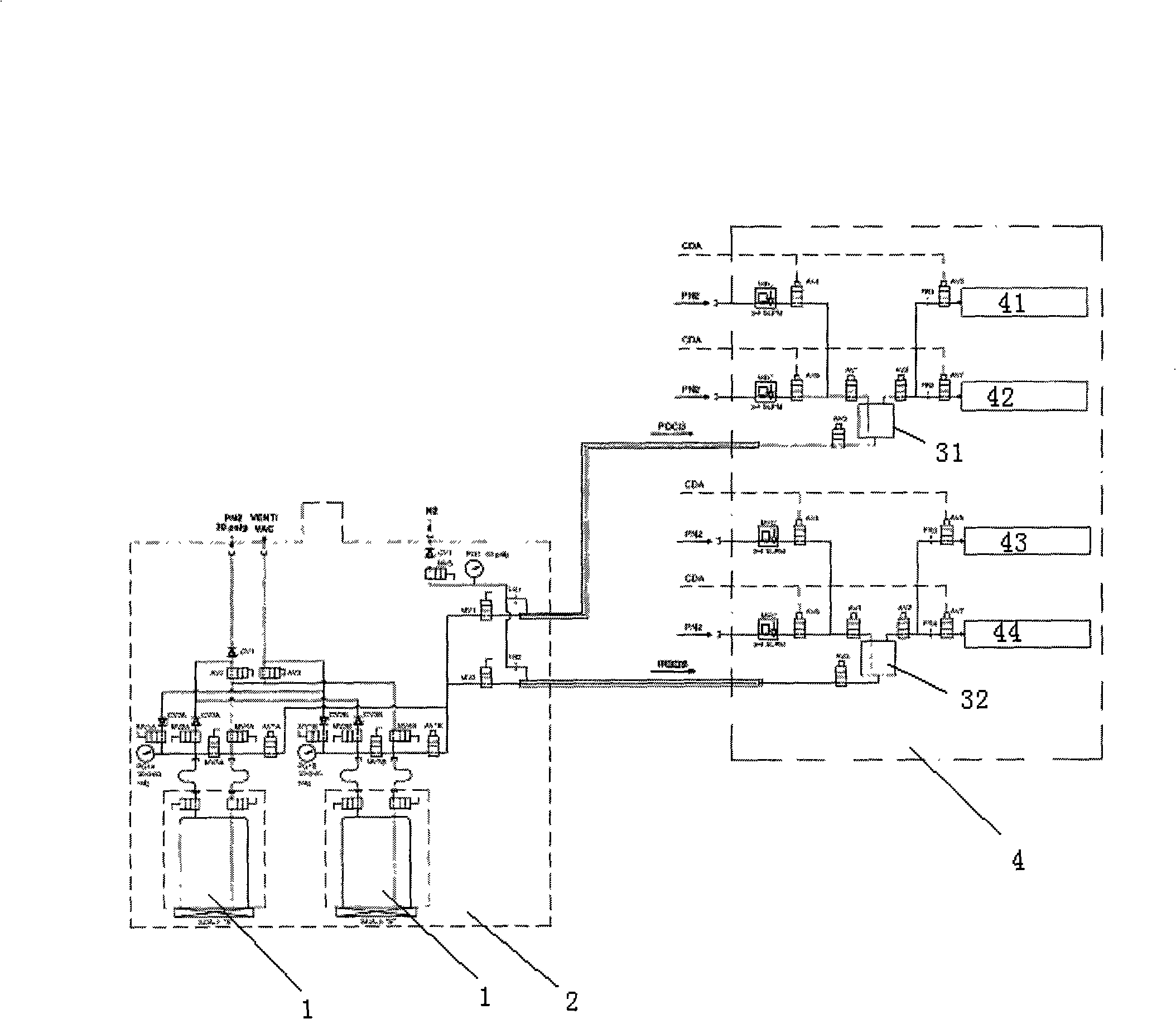

[0022] Such as figure 1 As shown, a safe delivery method of phosphorus oxychloride, the method adopts a new type of safe delivery device for phosphorus oxychloride, the delivery device mainly includes four parts: 19L source bottle container 1, automatic liquid replenishment device 2, drum Bubble device 3, flow control, etc. All containers and valves are specially treated against corrosion to ensure POCl 3 purity.

[0023] The source bottle is cylindrical, with a volume of 19L. It is made of stainless steel SS316L, equipped with two high-purity diaphragm valves for inlet and outlet, and a valve protection rod is installed on the top.

[0024] The automatic replenishment device 2 uses high-purity nitrogen, and POCl 3 The pressure is sent to No. 1 bubbler 31 and No. 2 bubbler 32 near the diffusion furnace 4 . The supply signal is derived from the demand command of the bubbler. The liquid replenishment device can hold two steel cylinders, equipped with an electronic scale, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com