Microstructure multifunction optical film diaphragm

An optical film, multi-functional technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of sacrificing the viewing angle, increasing the manufacturing cost of the film, etc., to reduce the cost, simplify the structure and optical design, and facilitate the manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

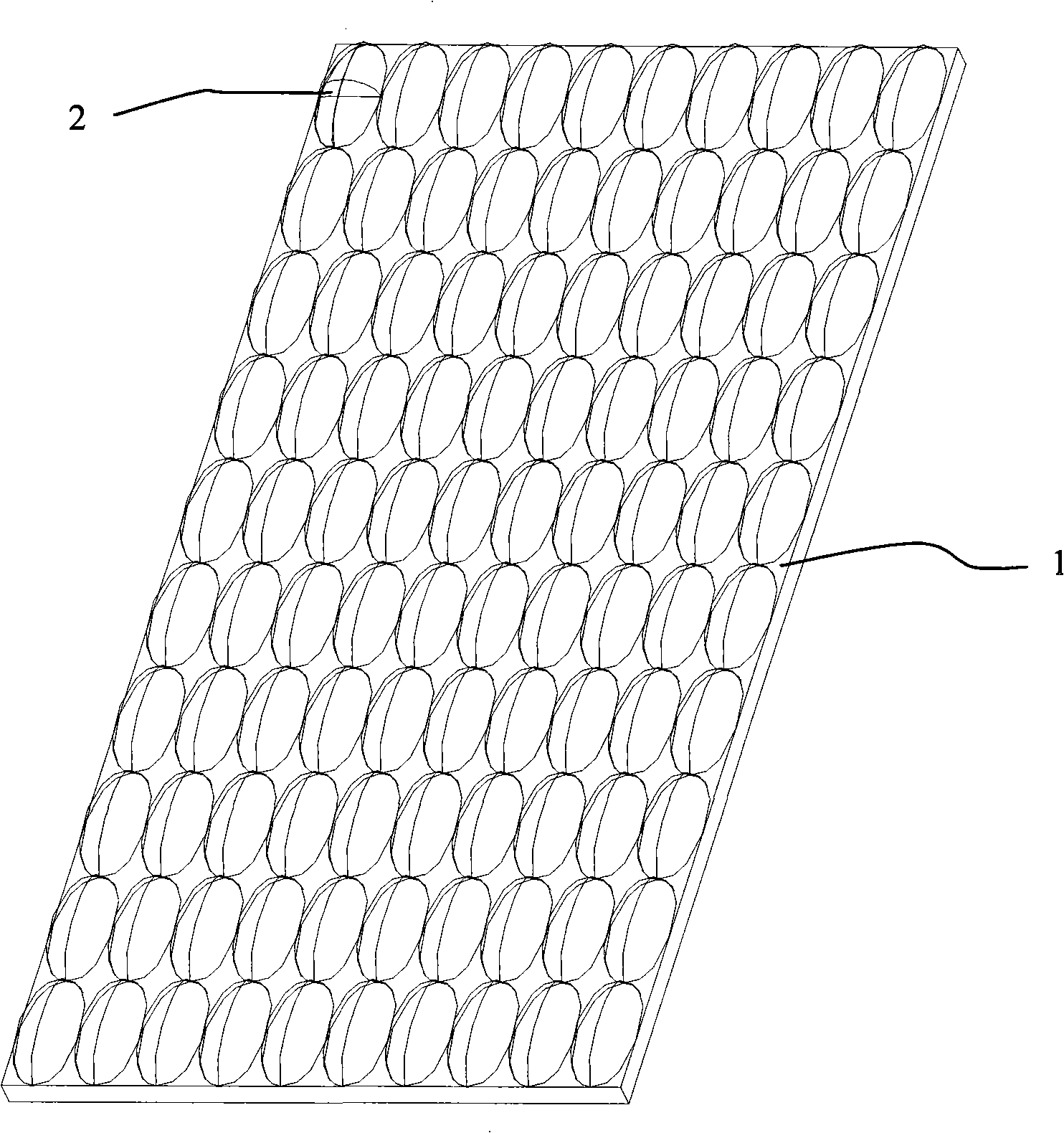

[0024] figure 1 It is a schematic diagram of the structure of the optical film of the present invention when used as a prism sheet, please refer to figure 1 , which is a preferred embodiment when the optical film of the present invention is used as a prism sheet. The optical film includes a light incident surface (not shown) and a light exit surface 1 opposite to the light incident surface. The light exit surface 1 has A plurality of micro-protrusion structures 2, the plurality of micro-protrusion structures are similar to semi-ellipsoidal structures. The light incident surface is a flat surface. The raised ellipsoidal structure is the tiny unit structure of the new membrane, which is different from any microstructure of the existing prism sheet.

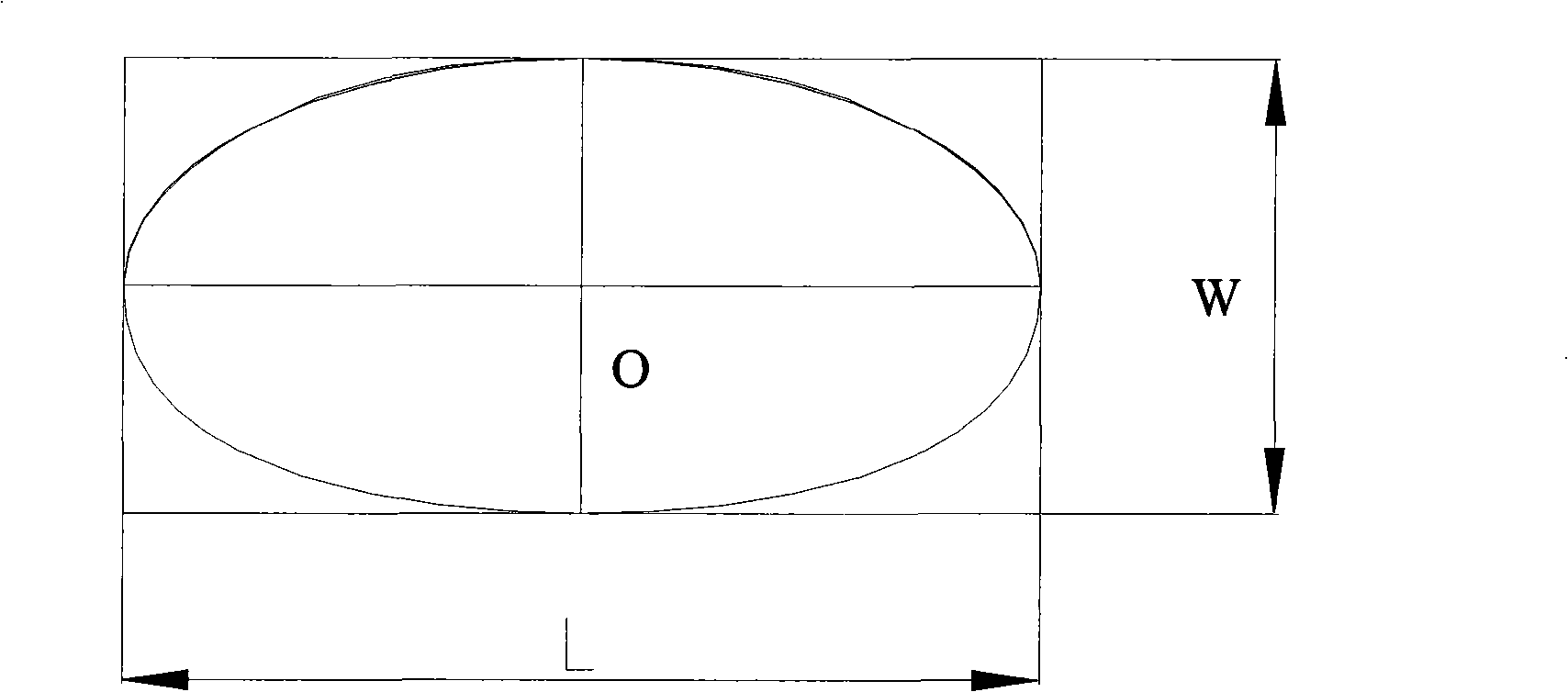

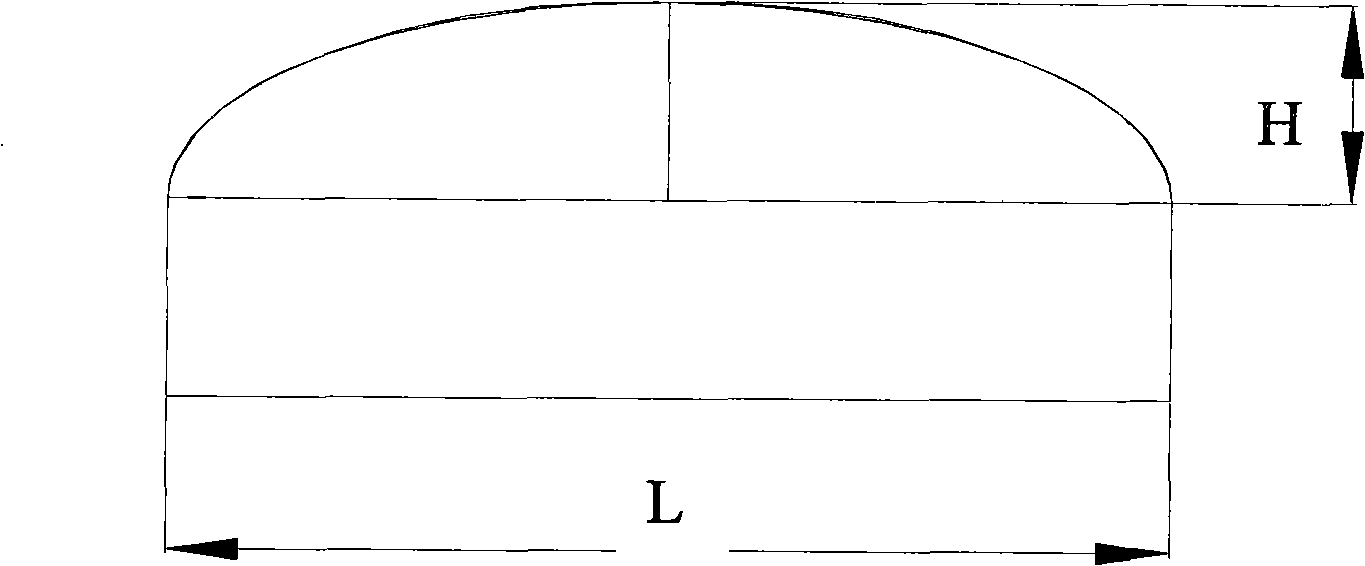

[0025] For a detailed schematic diagram of the above-mentioned microprotrusion structure, please refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com