Method for detecting electrical property of conductivity lead wire of glass substrate of liquid crystal display

A liquid crystal display and electrical performance testing technology, which is applied in the direction of nonlinear optics, measuring electronics, and measuring devices, can solve problems such as affecting test results, incomplete testing, and limiting production capacity, so as to ensure test results, improve production efficiency, The effect of avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

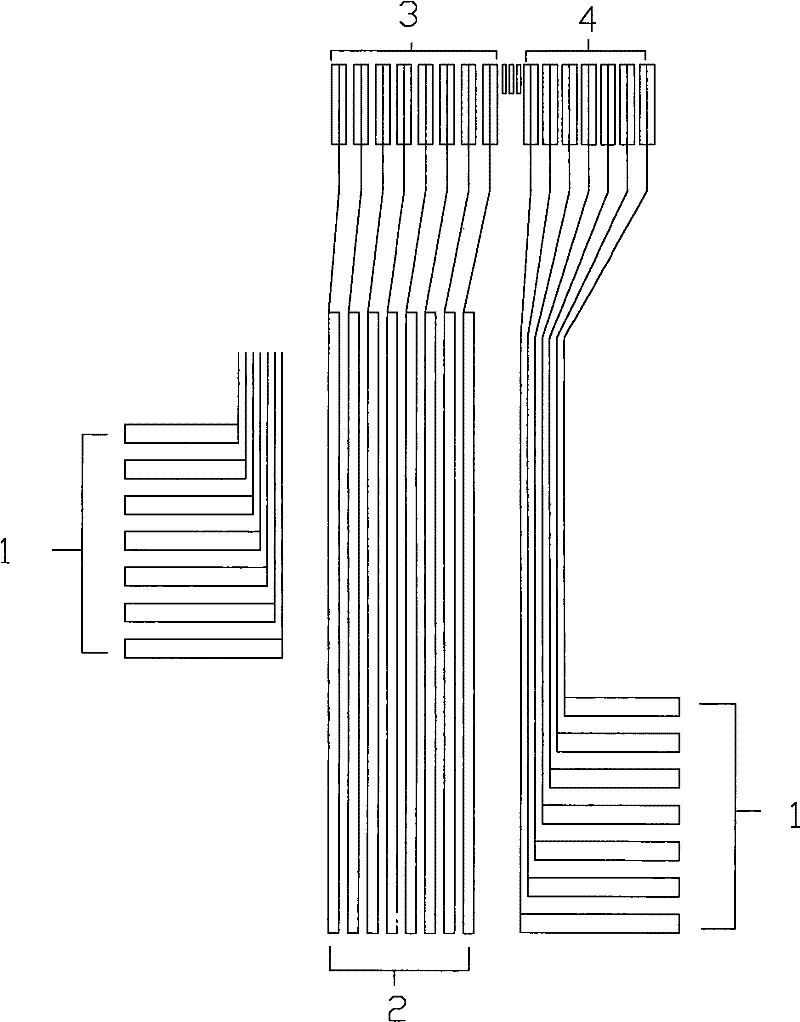

[0034] Such as figure 1As shown, a method for detecting electrical properties of conductive leads of a liquid crystal display glass substrate, the method is used to detect short circuit defects and open circuit defects, including the following steps:

[0035] The first step: if figure 1 As shown, the conductive leads on the glass substrate of the liquid crystal display are divided into column drive leads 2 and row drive leads 1 . Wherein the column driving lead 2 corresponds to the column (SEG) electrode 3 of the driving chip, that is, the column driving lead 2 is connected to the column (SEG) electrode 3 of the driving chip; the row driving lead 1 is connected to the row (COM) electrode 4 of the driving chip Correspondingly, the row driving wire 1 is connected to the row (COM) electrode 4 of the driving chip.

[0036] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com