Microwave band-elimination filter based on tree shaped microstrip line construction

A technology of microstrip line and microwave strip, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of insufficient stop-band attenuation, low production cost, narrow stop-band bandwidth, etc., and achieve cost and volume reduction, structure The effect of simple, large stopband bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

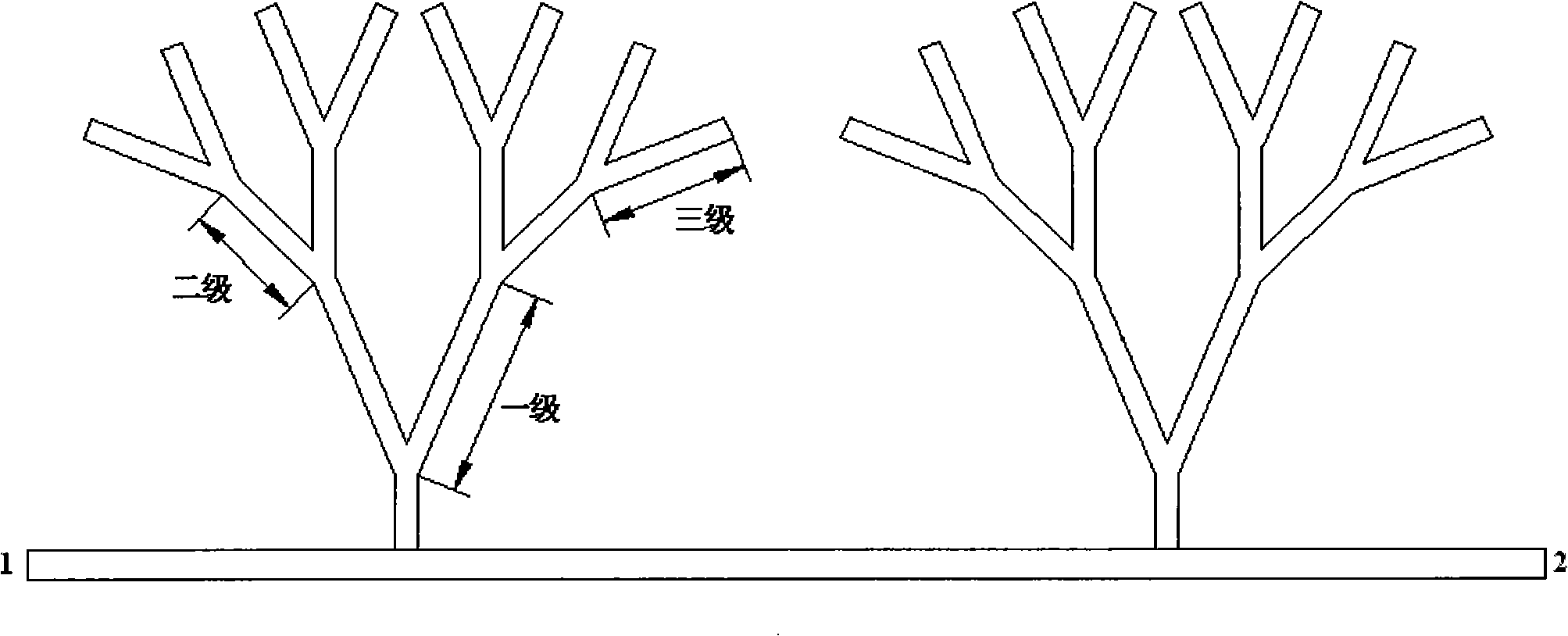

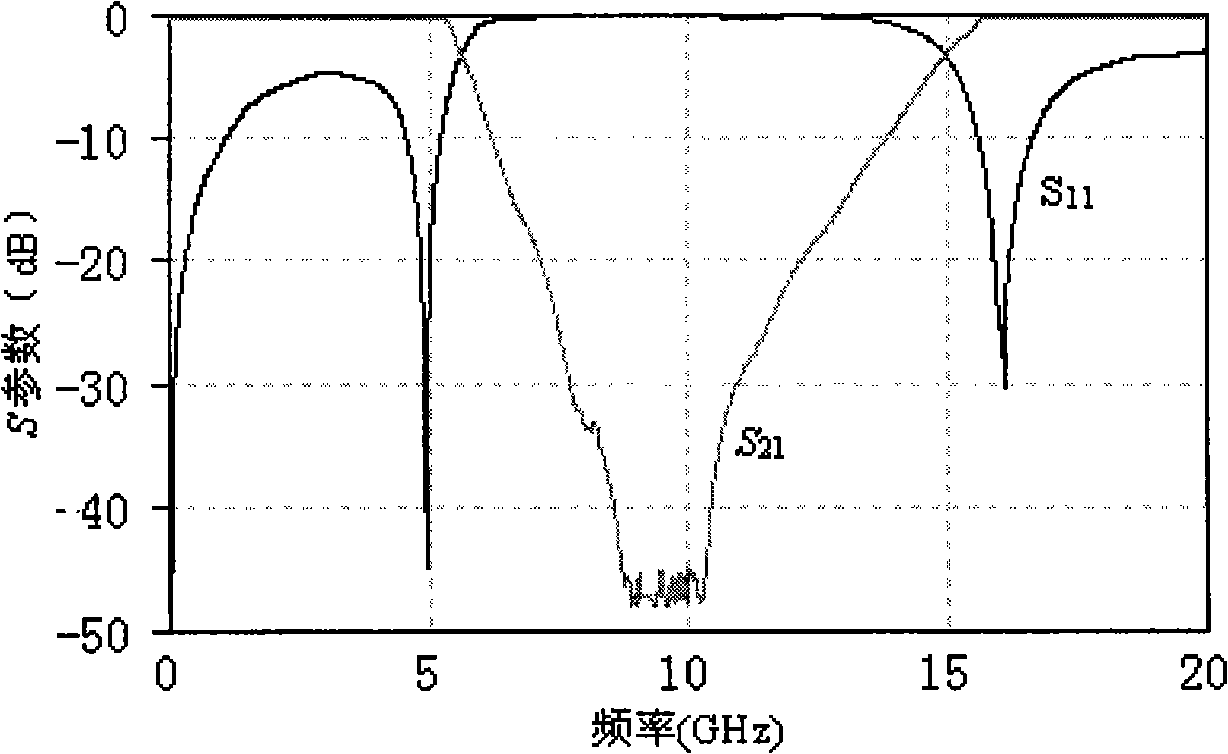

[0014] The structural size parameters of the microwave bandstop filter with tree-shaped microstrip line structure: 2 tree root microstrip lines, the length of the tree root microstrip line is 0.1mm, the opening angle of the V-shaped tree branch microstrip line is 30°, and the first-level V The length of the V-shaped branch microstrip line is 1.0mm, the length of the second-level V-shaped branch microstrip line is 0.5mm, the length of the third-level V-shaped branch microstrip line is 0.5mm, and the distance between the two root microstrip lines is 4.0mm. The line width is 0.1mm, the dielectric constant of the substrate is 2.0, and the thickness of the substrate is 0.2mm. figure 2 The performance curves of microwave band-rejection filters with two tree-shaped microstrip line structures are shown. The band-rejection filter has a stop-band bandwidth of up to 7GHz (from 6.5GHz to 13.5GHz), and the maximum stop-band attenuation is -48.7dB.

Embodiment 2

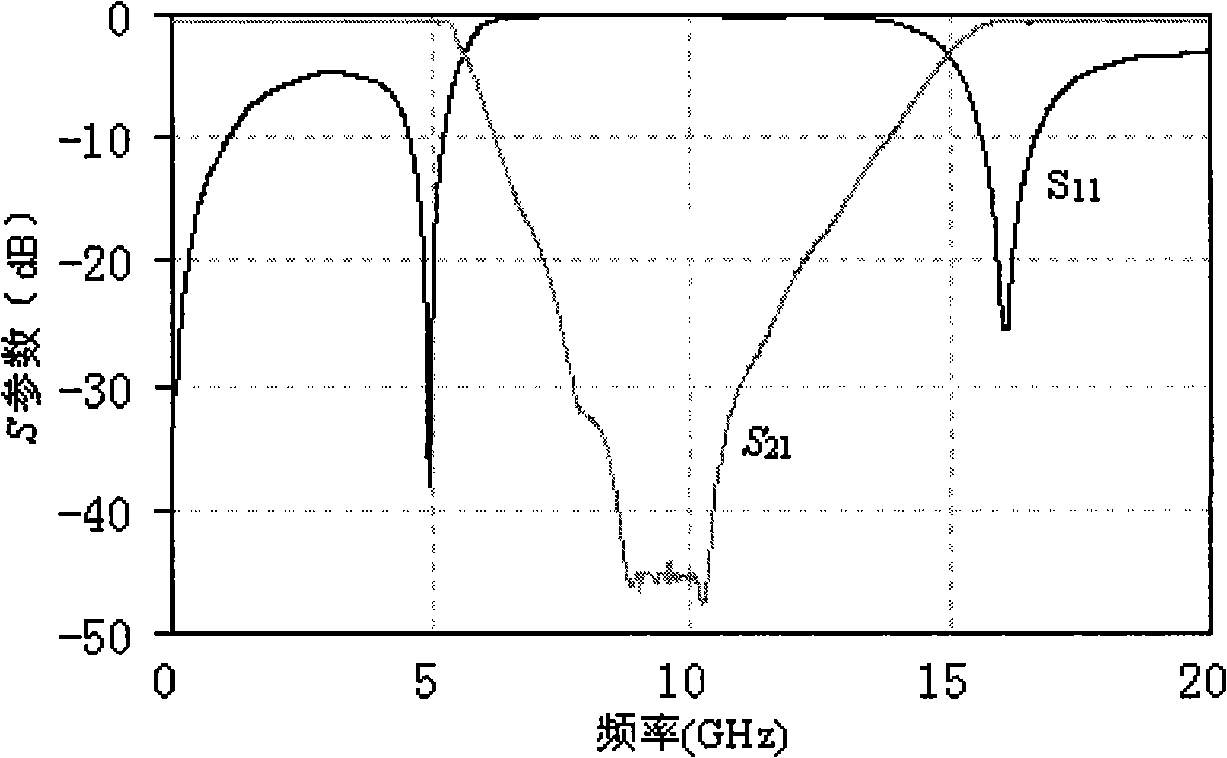

[0016] The structural size parameters of the microwave bandstop filter with tree-shaped microstrip line structure: 8 root microstrip lines, the length of the tree root microstrip line is 2.0mm, the opening angle of the V-shaped tree branch microstrip line is 90°, and the first-level V The length of the V-shaped branch microstrip line is 2.0mm, the length of the second-level V-shaped branch microstrip line is 1.0mm, the length of the third-level V-shaped branch microstrip line is 1.5mm, and the distance between the two root microstrip lines is 8.0mm. The line width is 0.6mm, the dielectric constant of the substrate is 16.0, and the thickness of the substrate is 3.0mm. image 3 The performance of the microwave band-rejection filter with 8 tree-shaped microstrip line structures is shown. The band-rejection filter has a stop-band bandwidth of 7 GHz (from 6.5 GHz to 13.5 GHz), and the maximum stop-band attenuation is -47.65 dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com