Rolling mill hydraulic AGC system and control method thereof

A control method and rolling mill technology, applied in rolling mill control devices, digital control, metal rolling, etc., can solve problems affecting control accuracy, large lag, and system instability, and achieve reliable operation, simple installation and debugging, and feedback response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

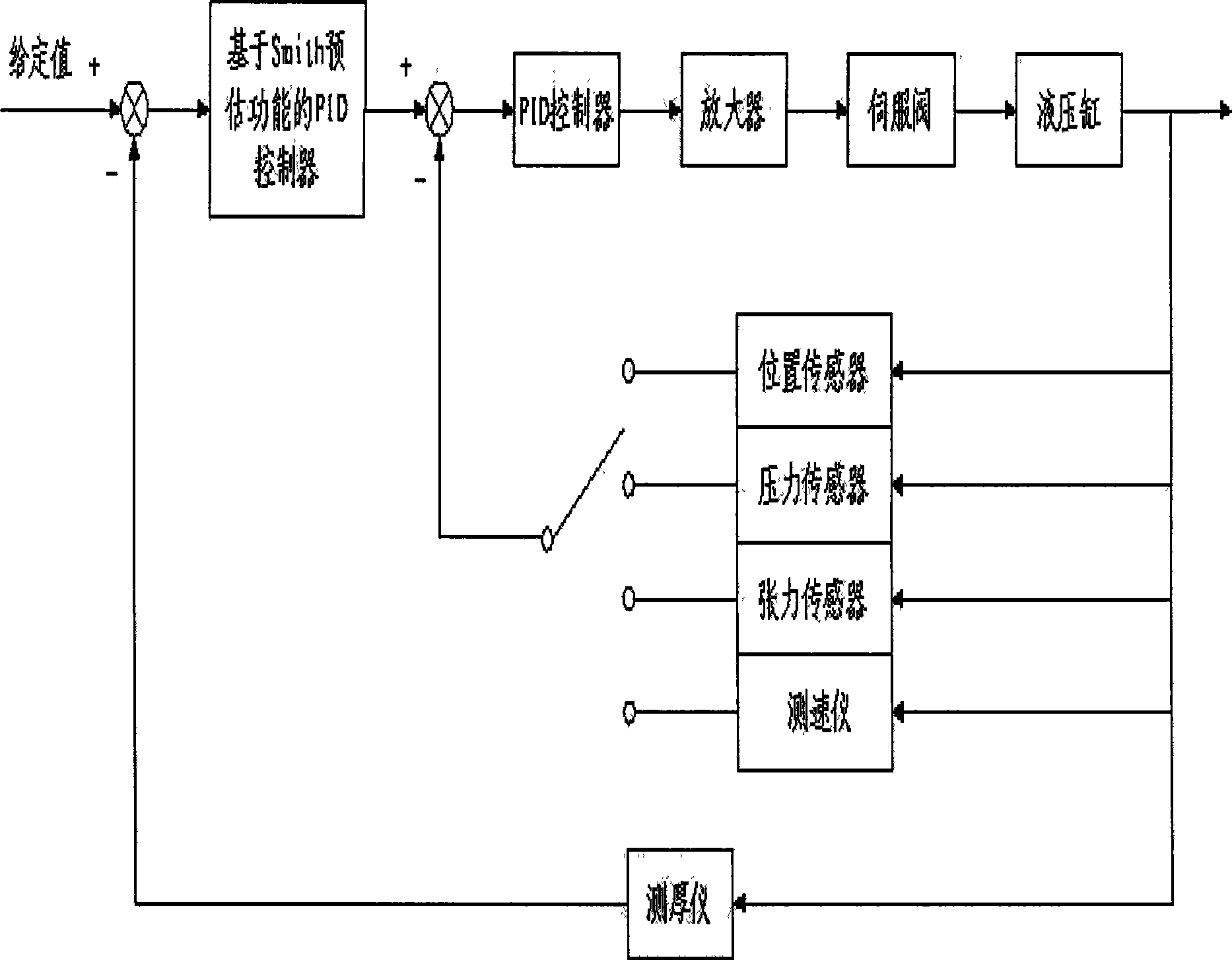

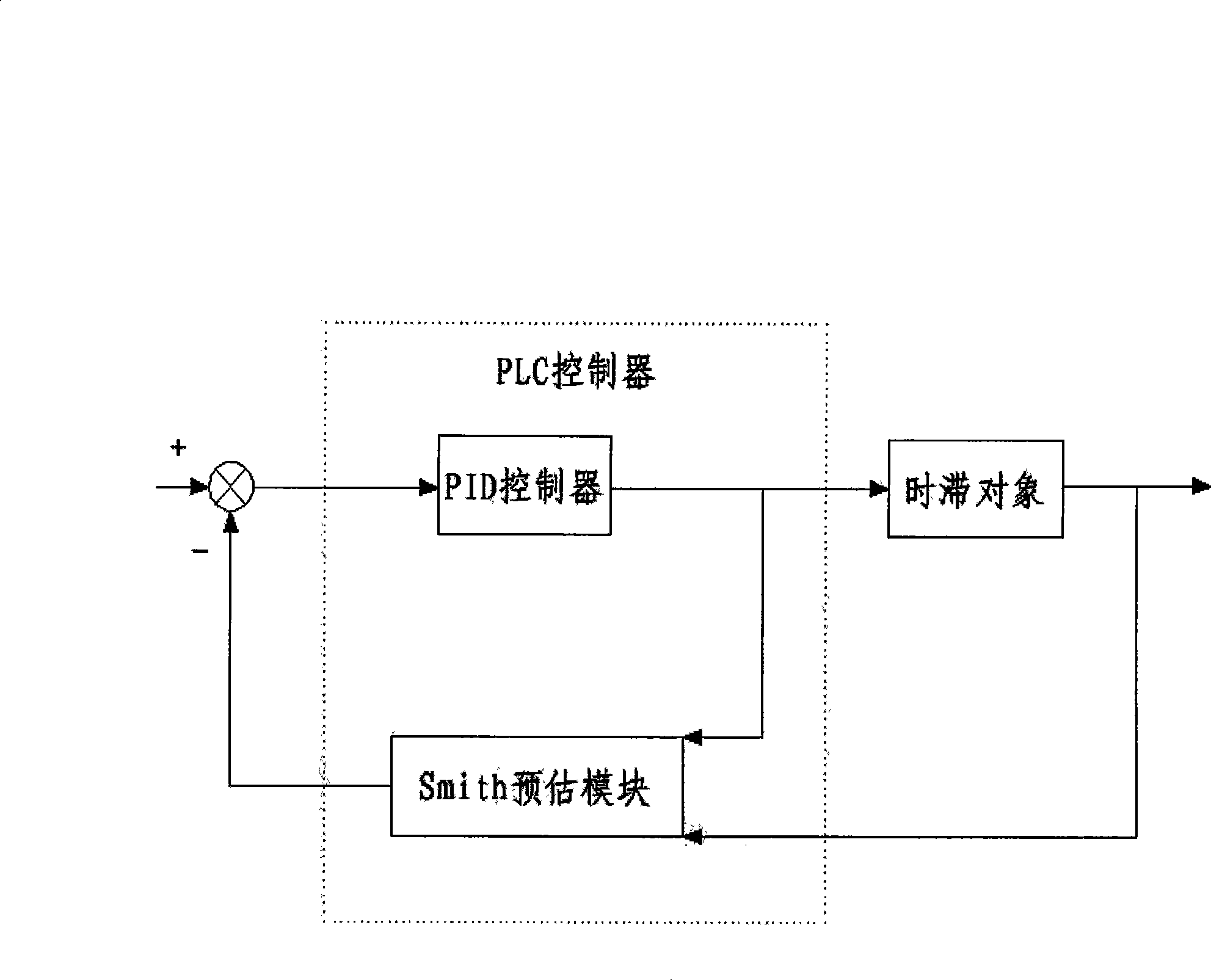

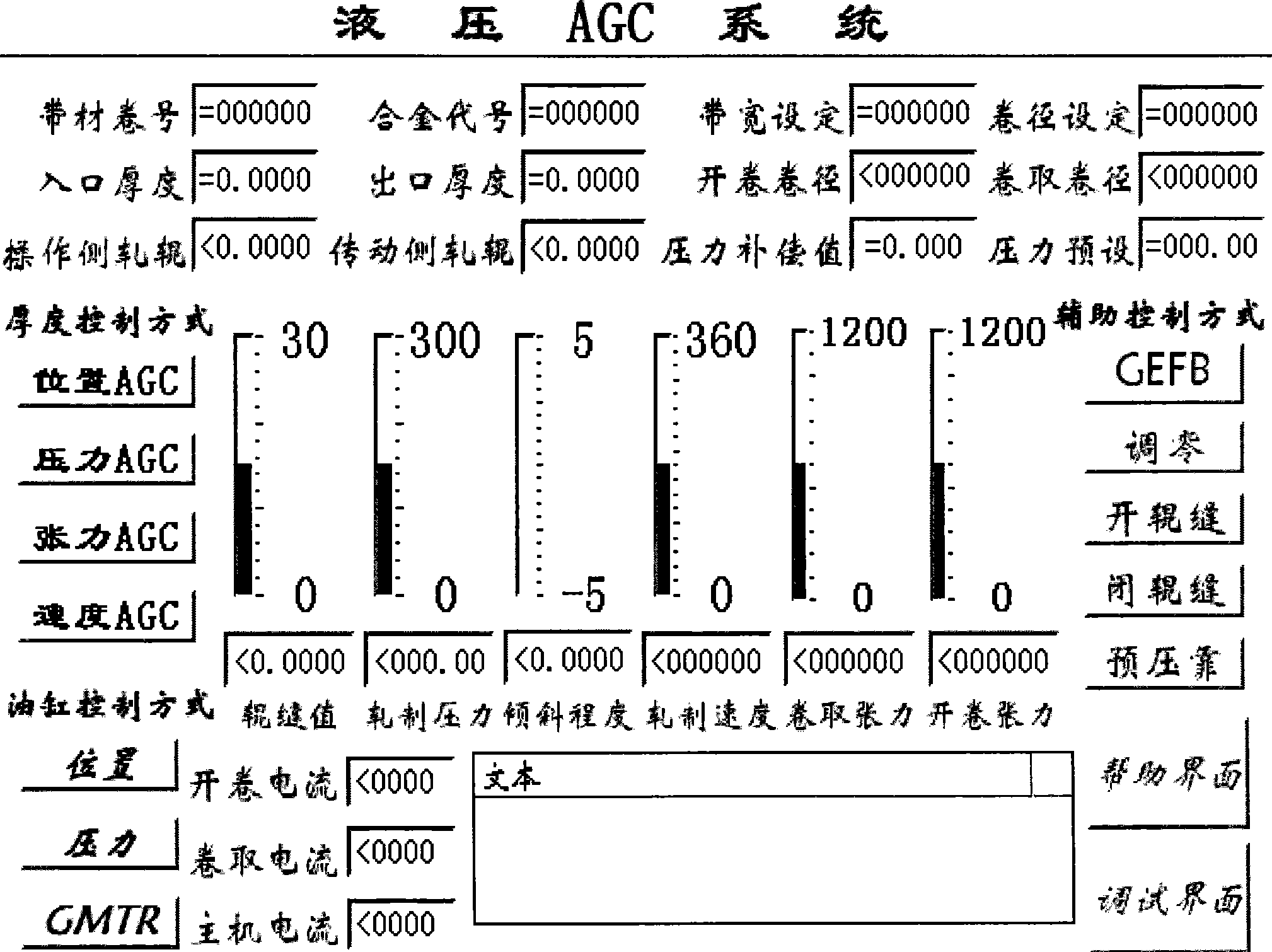

[0019] like figure 1 The shown hardware part of the present invention includes an amplifier, a servo valve and a hydraulic cylinder connected in series in sequence; a PID controller is connected in series at the front end of the amplifier. The position sensor, pressure sensor, tension sensor and tachometer are connected in parallel. like figure 2 As shown, the Smith predictor and the PID controller are incorporated into the programmable controller PLC, and one end is connected to the input of the given value, and the other end is connected to the time-delay object. The programmable controller PLC is an electronic digital operation operation. The system is currently designed for general use in industrial environments. The whole system is formed by connecting the outer loop closed loop and the inner loop single closed loop in a double closed loop mode. The thickness gauge is connected to the input end of the PID controller based on the Smith predictor function, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com