Automatic disassembling device of circuit board device

A technology for circuit boards and components, applied in the field of automatic dismantling devices, can solve the problems of high workload of operators, inconvenient to protect human health, improve occupational safety, inability to realize automatic/semi-automatic disassembly, etc., and achieve noise removal. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

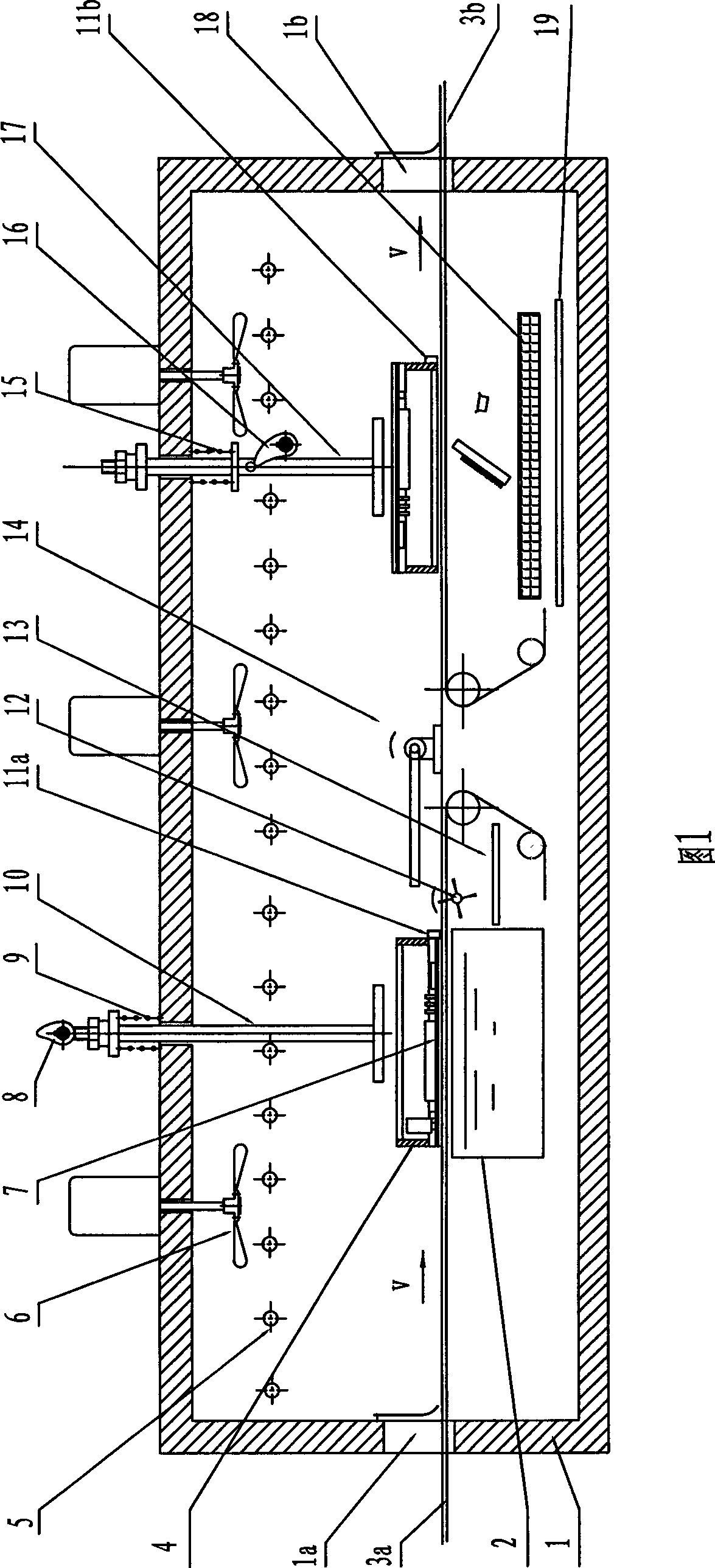

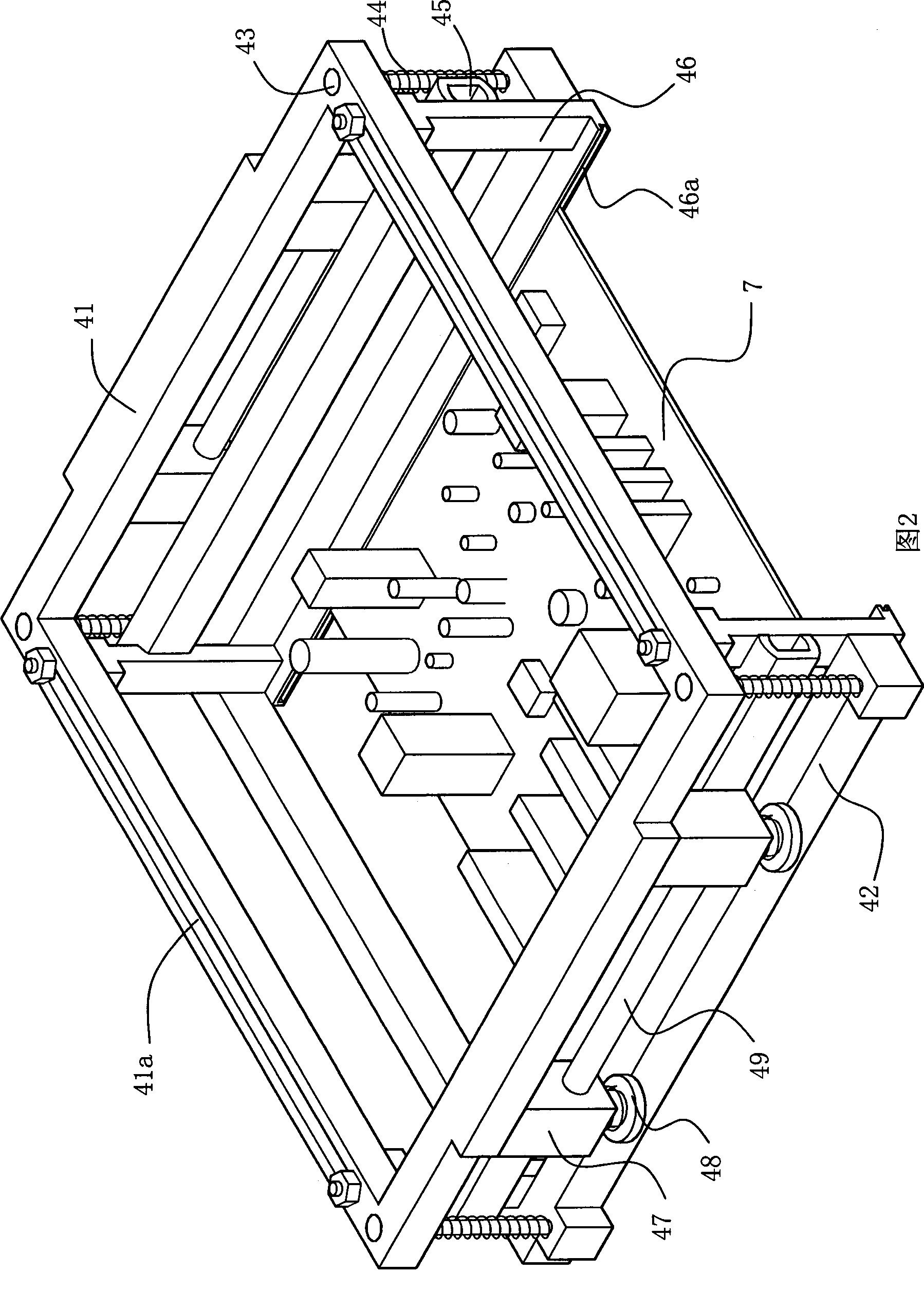

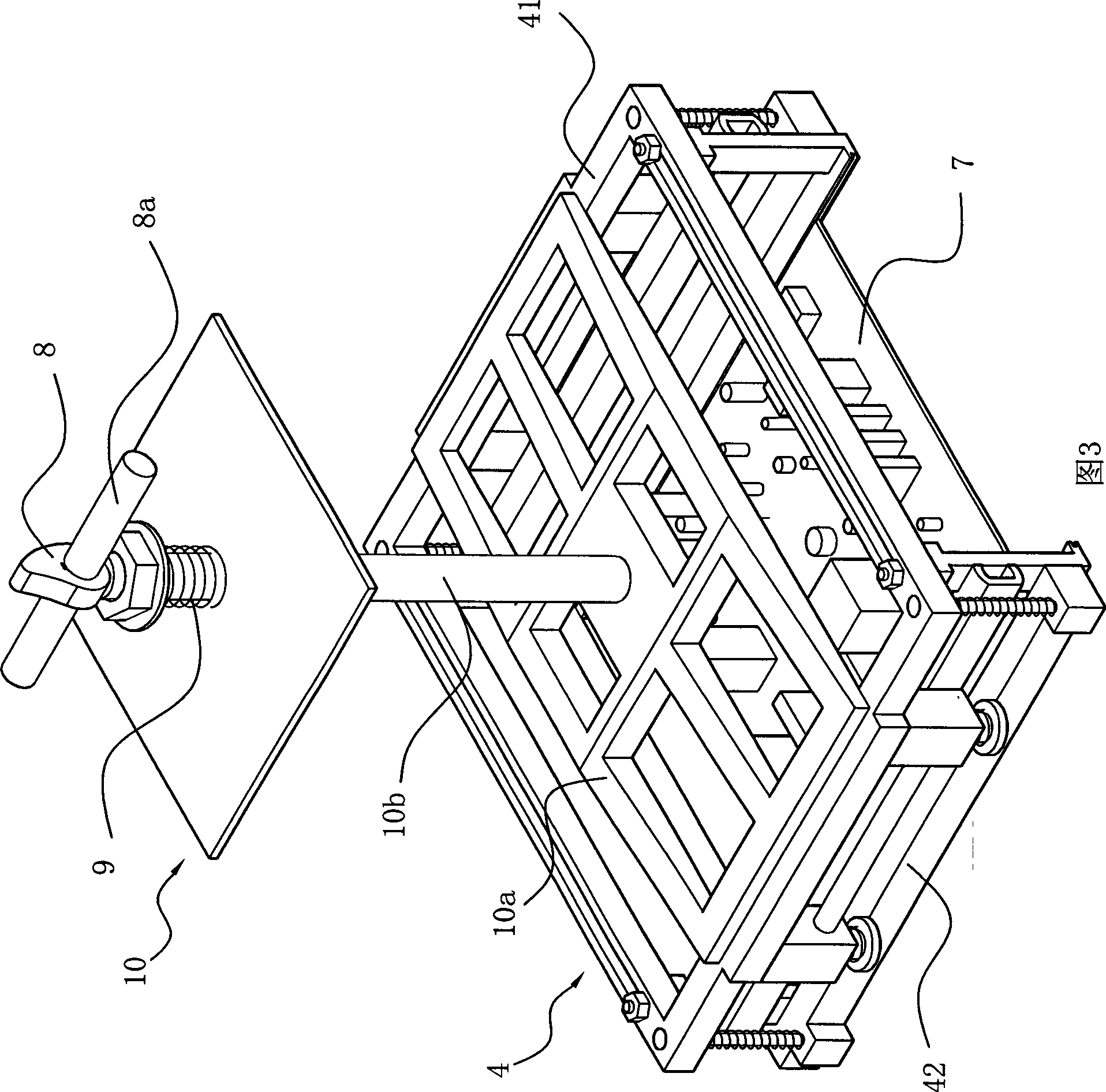

[0023]Referring to Fig. 1 to Fig. 5, the automatic dismantling device of the circuit board components of the present embodiment comprises the incubator 1 that is provided with inlet 1a and outlet 1b, and the inner wall of described incubator 1 is provided with a plurality of heating pipes 5 for heating The inner top of the thermostat 1 is provided with several fans 6 for adjusting the heat in the balance chamber; the thermostat 1 is also provided with a molten solder heating furnace 2, a steel wire roller brush 12, a turning transfer mechanism 14, Vibration and impact device 17, a device for making the soldering surface of the circuit board contact the molten solder in the molten solder heating furnace, the first solder land 13, the second solder land 19, and the component collection mesh belt 18. The molten solder heating furnace 2 is positioned at one side near the inlet 1a of the thermostat, and is fixed on a supporting seat (not shown) provided with in the thermostat with b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com