Method and apparatus for engine control during auto-ignition combustion

一种内燃发动机、发动机的技术,应用在燃烧发动机、发动机控制、内燃活塞发动机等方向,能够解决控制系统稳态值滞后等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

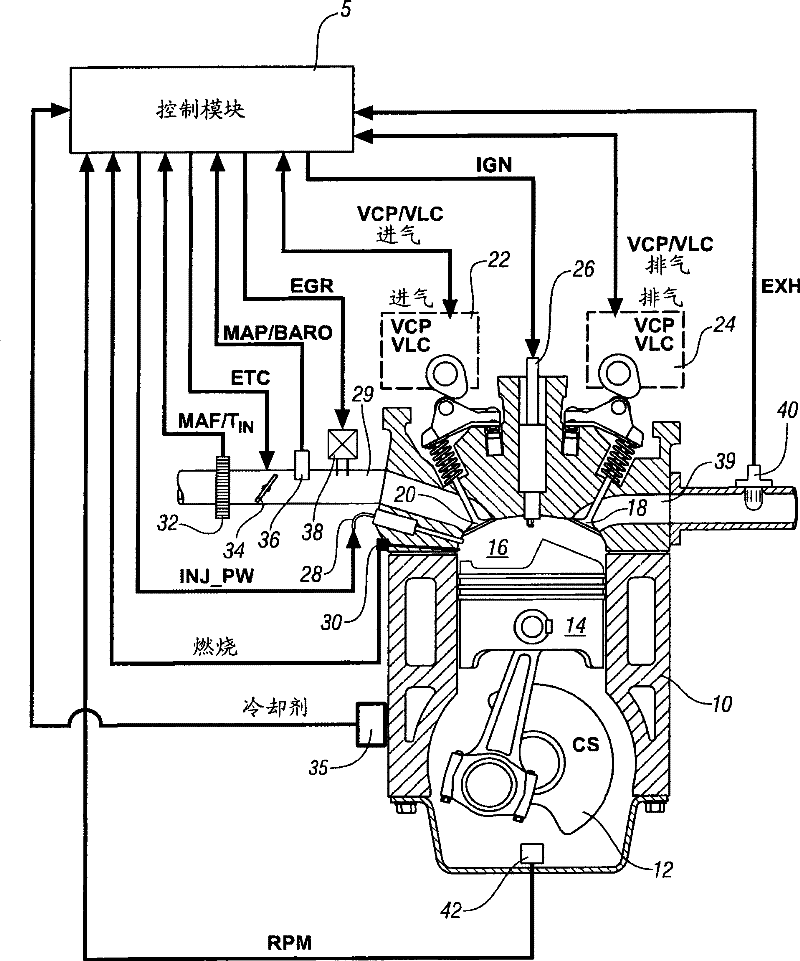

[0016] Referring now to the accompanying drawings, the description is only used to illustrate the purpose of the present invention, not to limit it. figure 1 A schematic diagram of an internal combustion engine 10 and an accessory control module 5 constructed according to an embodiment of the present invention is described.

[0017] The exemplary engine 10 includes a multi-cylinder direct injection four-stroke internal combustion engine having a reciprocating piston 14 slidable in a cylinder, the piston 14 defining a variable volume combustion chamber 16. Each piston is connected to a rotating crankshaft 12 ('CS'), and the linear reciprocating motion of the pistons is converted into rotary motion by the rotating crankshaft 12. The intake system provides intake air to the intake manifold, which introduces the air entering the intake passage 29 and distributes it to each combustion chamber 16. The air intake system includes airflow duct systems and devices for monitoring and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com