High-efficiency heat exchange tube with minuteness passage

A technology of micro-channels and heat exchange tubes, applied in tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency, increase heat exchange efficiency, increase fluid flow velocity, and enhance heat exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

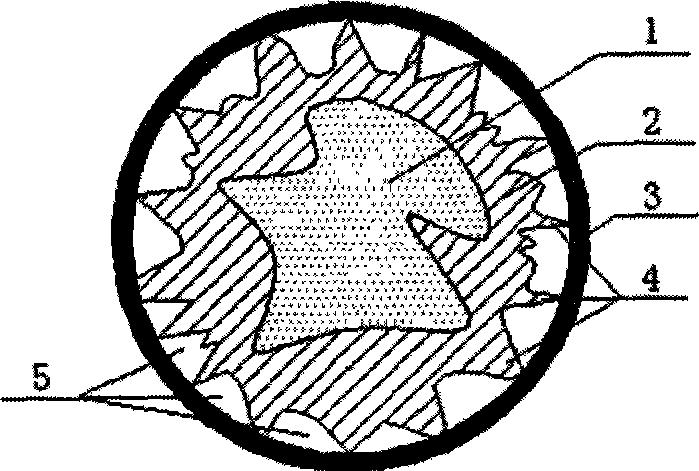

Embodiment 1

[0046] Embodiment 1: as image 3 As shown, the high-efficiency heat exchange tube with a micro-channel structure of the present invention is composed of an outer tube 3 and a non-conductive inner tube 2 with a blocking body 1 at both ends or its lumen; the outer diameter of the inner tube 2 used is 6mm, its outer wall has a spiral convex tooth structure 5 with a spiral triangular structure, the inner diameter of the outer tube 3 is 9mm, and its inner wall is smooth, so about 16 nearly trapezoidal fine channels 4 are formed between the inner tube 2 and the outer tube 3, The hydraulic diameter of the microchannel is about 0.5 mm. The inner pipe 2 and the outer pipe 3 are tightly connected by pipe expansion or welding. The pipes are made of aluminum, and under the same flow rate, the heat exchange efficiency of this pipe is more than 20% higher than that of ordinary aluminum pipes with the same diameter.

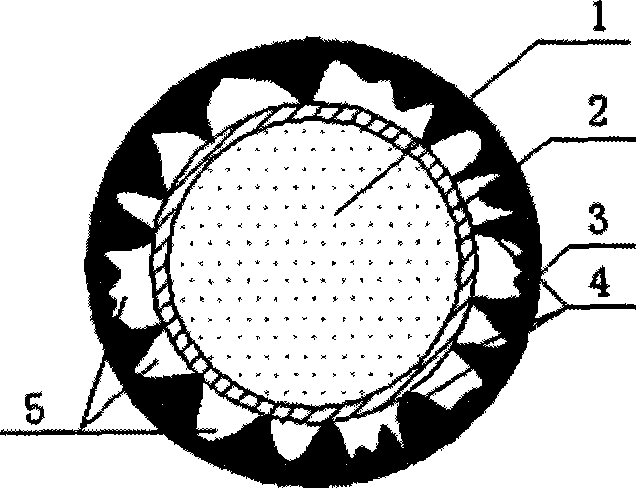

Embodiment 2

[0047] Embodiment 2: as Figure 4 As shown, the high-efficiency heat exchange tube with a fine channel structure of the present invention is composed of an outer tube 3 and a non-conductive inner tube 2 with a blocking body 1 at both ends or in a certain lumen; the inner and outer diameters of the outer tube are 9 mm, and the inner wall There are straight protruding teeth 5 with a triangular structure, the outer diameter of the inner tube 2 is 6 mm, and its outer wall is smooth, and 16 nearly trapezoidal straight micro-channels 4 are formed between the two tubes. The hydraulic diameter of the micro-channels is about 1 mm. Using copper tubes, under the same flow rate, its heat exchange efficiency is more than 10% higher than that of ordinary internal threaded copper tubes with the same diameter.

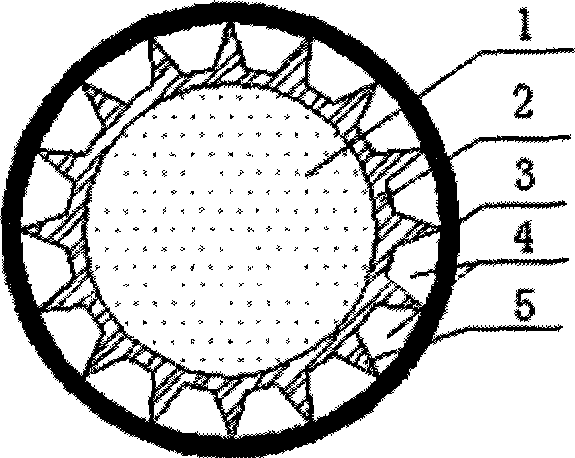

Embodiment 3

[0048] Embodiment 3: as Figure 5 As shown, the high-efficiency heat exchange tube with micro-channel structure of the present invention is composed of an outer tube 3 and a non-conductive inner tube 2 with a blocking body 1 at both ends or in a lumen; the outer diameter of the inner tube 2 is 6mm, Its outer wall has spiral convex teeth 5 with a spiral trapezoidal structure, the inner diameter of the outer tube 3 is 9mm, and its inner wall is an internal thread structure, through the combination of the spiral convex teeth 5 and the internal thread of the outer tube, a plurality of spiral fine channels 4 are formed therebetween. The hydraulic diameter of the micro-channel is about 1mm, and the pipe is made of copper pipe. Since the internal thread in the micro-channel increases the heat transfer area and fluid turbulence, the heat transfer efficiency of this pipe is higher than that of the same pipe at the same flow rate. The diameter of ordinary copper pipes is increased by mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com