Thermopile infrared detection device

A detection device, infrared technology, applied in the direction of measuring devices, electric radiation detectors, photometry, etc., can solve the problems of increased man-hours and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

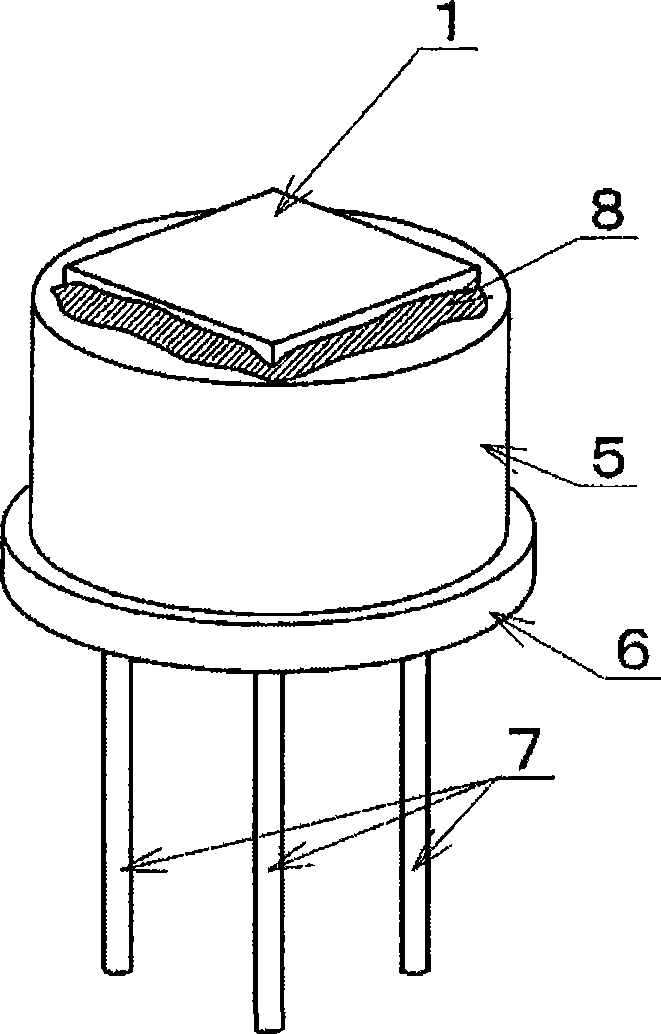

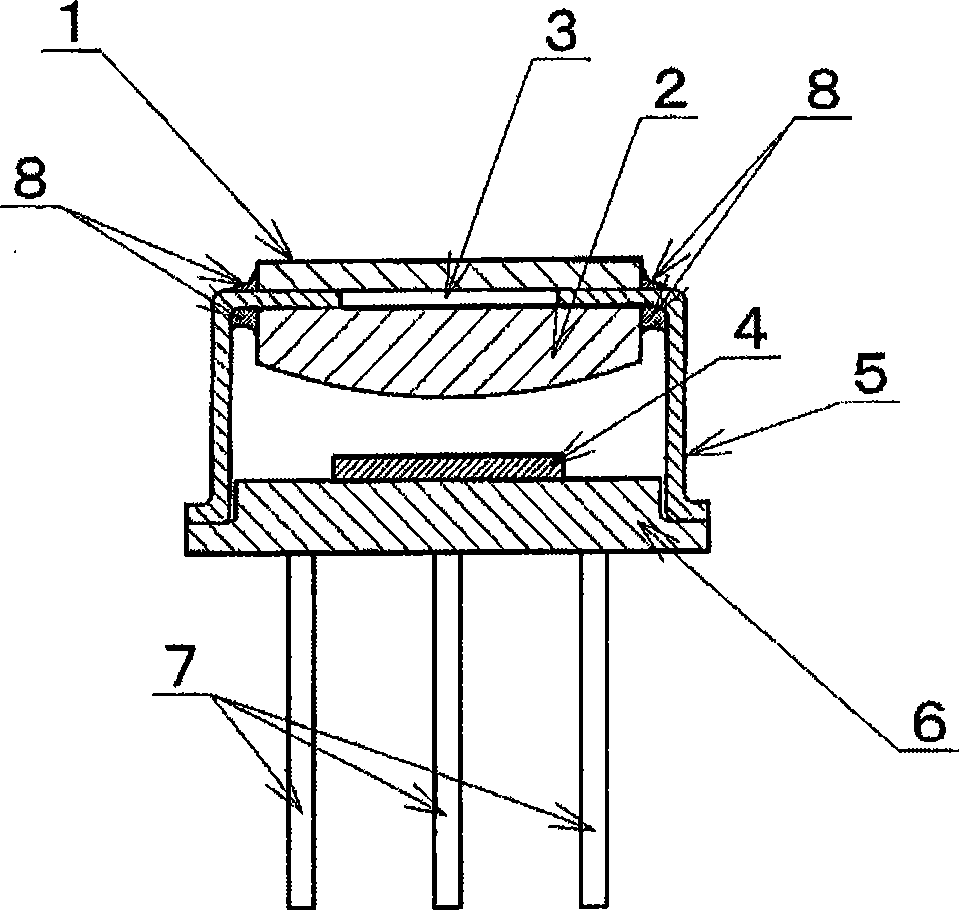

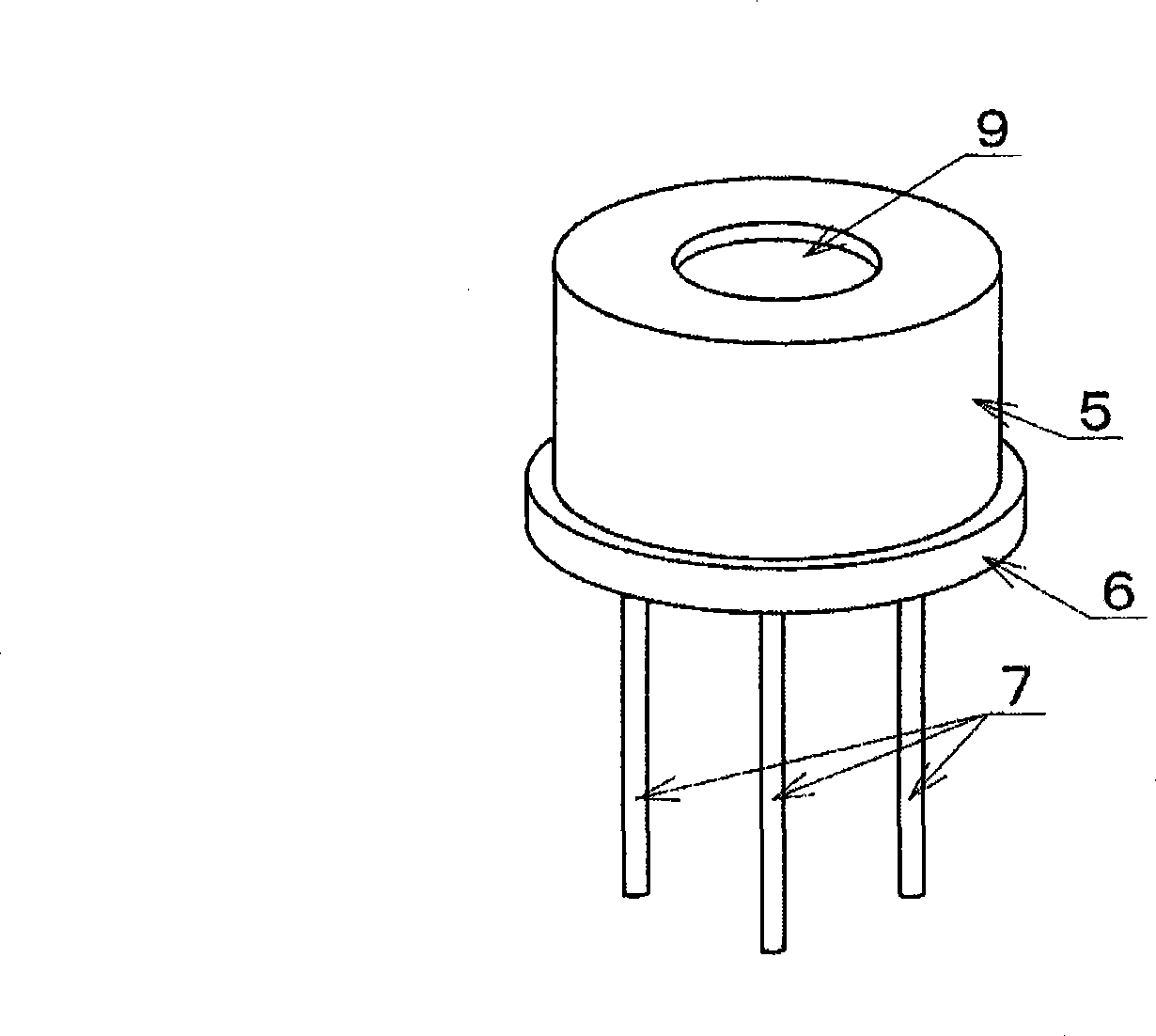

[0035] The present invention will be described in detail below using examples. figure 1 It is the most basic embodiment of the present invention, and shows the installation mode of the non-coated silicon plano-convex lens and the vapor-coated flat filter as the optical design part of the thermal pile sensor type infrared detection device. figure 2 Shows a schematic diagram of the internal cross-sectional structure.

[0036] In this embodiment, the structure is made such that the infrared incident amount of the thermal stack chip, which can measure the amount of radiated infrared rays of the object and detect the temperature of the object by receiving infrared rays, is projected by the object through optical design. The plano-convex lens made of silicon in the infrared detection area specified in the area, together with the metal can shell with infrared transmission window and the head with the lead terminal electrically connected to the thermal stack chip, is directed to pre...

Embodiment 2

[0043] Image 6 It shows the non-coated silicon plano-convex lens and the 5 μm non-coated silicon plano-convex lens used in Example 1 as the optical design part of the thermal-pile infrared detection device with the plane side and the convex side oppositely disposed. The way the coating plane filter is installed. Figure 7 Shows a schematic diagram of the internal cross-sectional structure.

[0044] Also can obtain and embodiment 1 in this embodiment Figure 5 The same infrared rays pass through the area.

Embodiment 3

[0046] Figure 8 The non-coated silicon plano-convex lens used in Example 1 and the non-coated silicon plano-convex lens used in Example 1 and the 5 μm coated flat filter by vapor deposition are shown as the optical design part of the thermal-pile infrared detection device with a front-to-back structure. Convex lens and 5μm planar filter are installed by evaporation coating. Figure 9 Shows a schematic diagram of the internal cross-sectional structure.

[0047] Also can obtain and embodiment 1 in this embodiment Figure 5 The same infrared rays pass through the area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com