Stage suspender height monitoring system and monitoring method thereof

A monitoring system and boom technology, applied in the field of grating sensors, can solve the problems of difficulty in guaranteeing accuracy, low detection precision, and high difficulty in operation, and achieve the effects of ensuring consistent height measurement, realizing integrated control, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

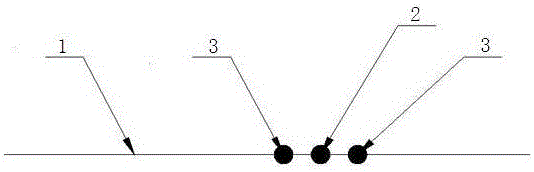

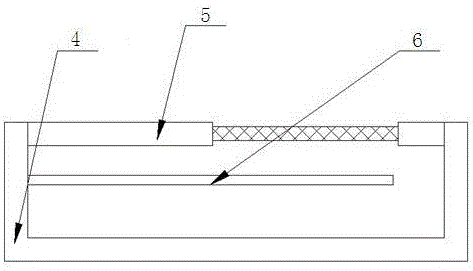

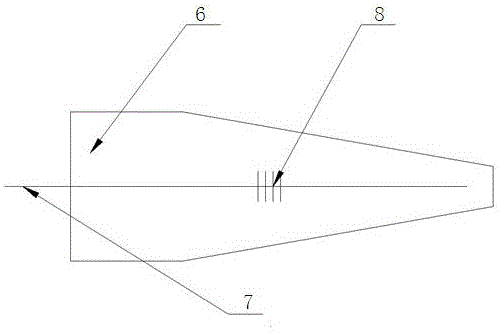

[0031] Such as figure 1 , 2 , 3, the present embodiment provides a stage boom height monitoring system, including an acoustic wave receiving unit 3, an acoustic wave emitting unit and a fiber grating sensor, and the acoustic wave emitting unit is composed of a sequentially connected single-chip microcomputer, an emission drive circuit, and a directional emission switch The acoustic wave receiving unit is composed of a cantilever beam 6, a casing 4 and an outer cover 5 installed on the casing with a filter screen. The cantilever beam 6 is provided with a fiber grating sensor, and the fiber grating sensor is connected to the cantilever beam 6. The fiber grating demodulator is connected, the fiber grating demodulator is connected with the computer, and the directional emission transducer 2 and the acoustic wave receiving unit 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com