Substrate outer appearance inspection device

A technology for visual inspection devices and substrates, which is applied to measuring devices, optical devices, and material analysis through optical means, and can solve problems such as difficulty in dealing with substrates with high components, inability to cope with substrates, and miniaturization of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

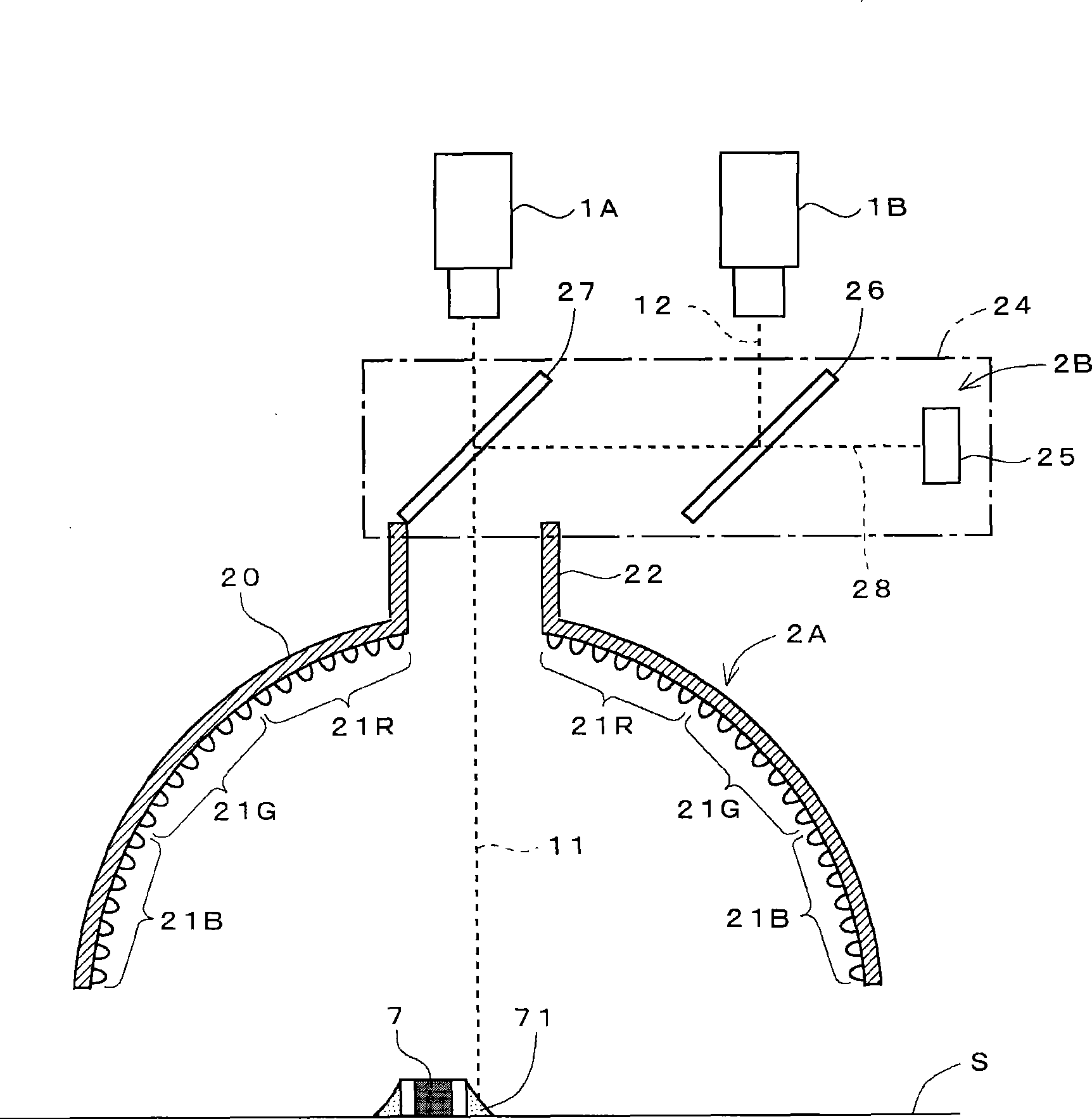

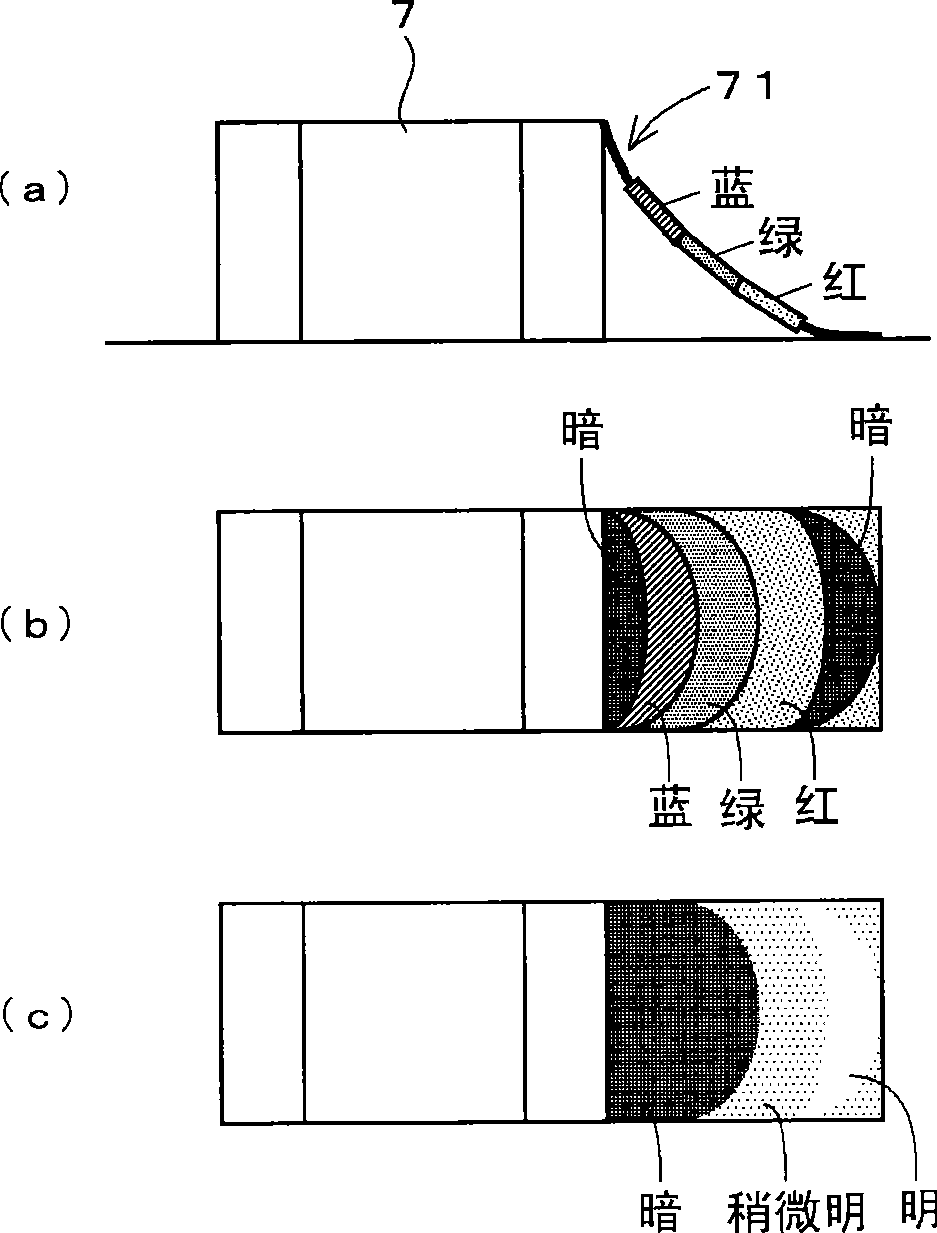

[0039] Next, an example of a substrate visual inspection device that inspects a substrate after a series of processes (solder printing process, component mounting process, and soldering process) for manufacturing a component-mounted substrate and inspects the appearance of each component will be described. Whether the installation state and the shape of the solder fillet are appropriate.

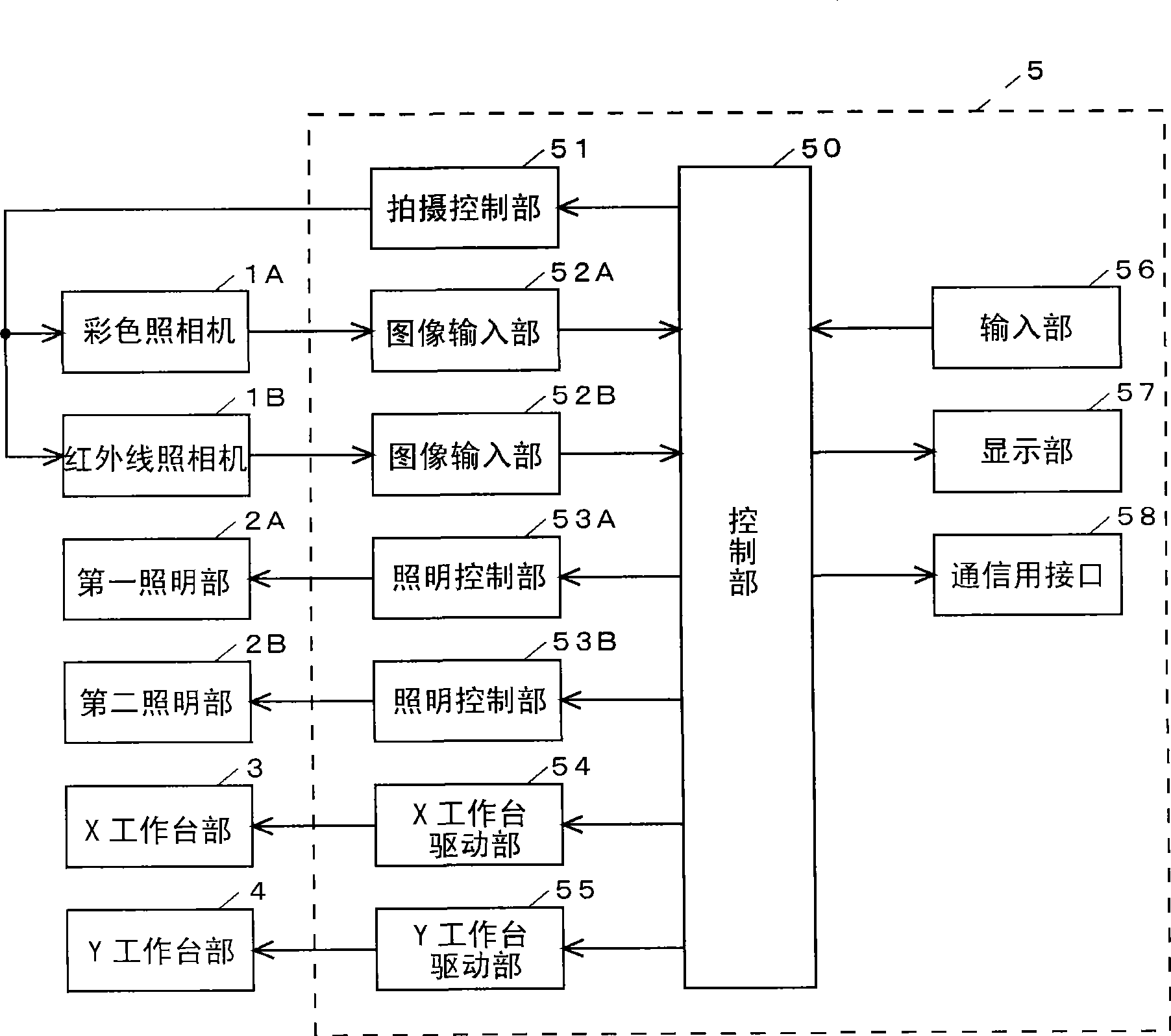

[0040] figure 1 It is a block diagram showing an example of the electrical configuration of the substrate appearance inspection device of this embodiment.

[0041] The inspection device is respectively provided with two cameras 1 and lighting units 2 as devices for generating substrate images of inspection objects (hereinafter, the cameras 1 and the lighting units 2 that have a corresponding relationship are combined, and symbols A and B are used to distinguish each Group). In addition, this inspection device is provided with an X stage unit 3, a Y stage unit 4, a control processing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com