Optical membrane

A technology of optical film and convex lens, applied in optics, optical components, nonlinear optics, etc., can solve problems such as user discomfort, collapse, and inability to improve brightness at small viewing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

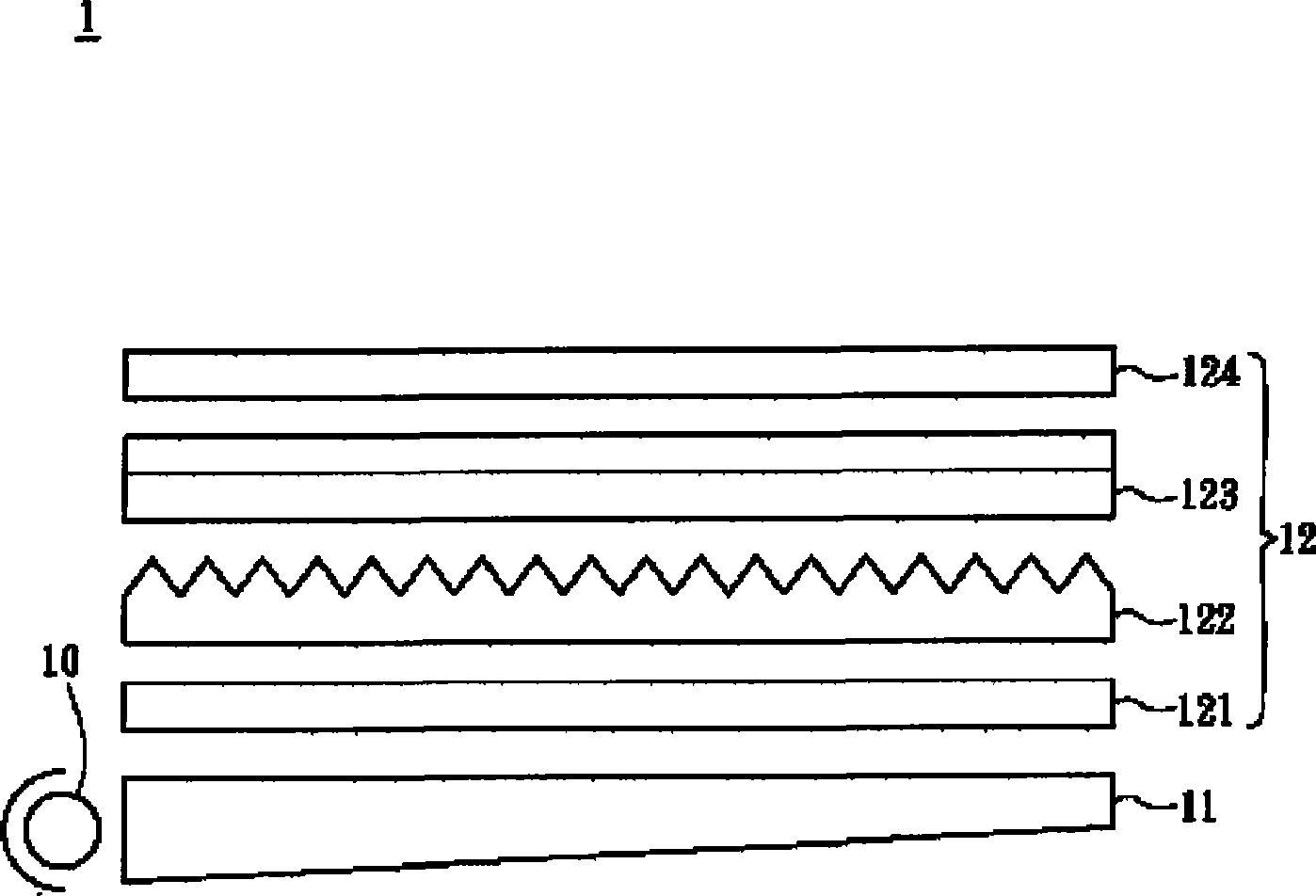

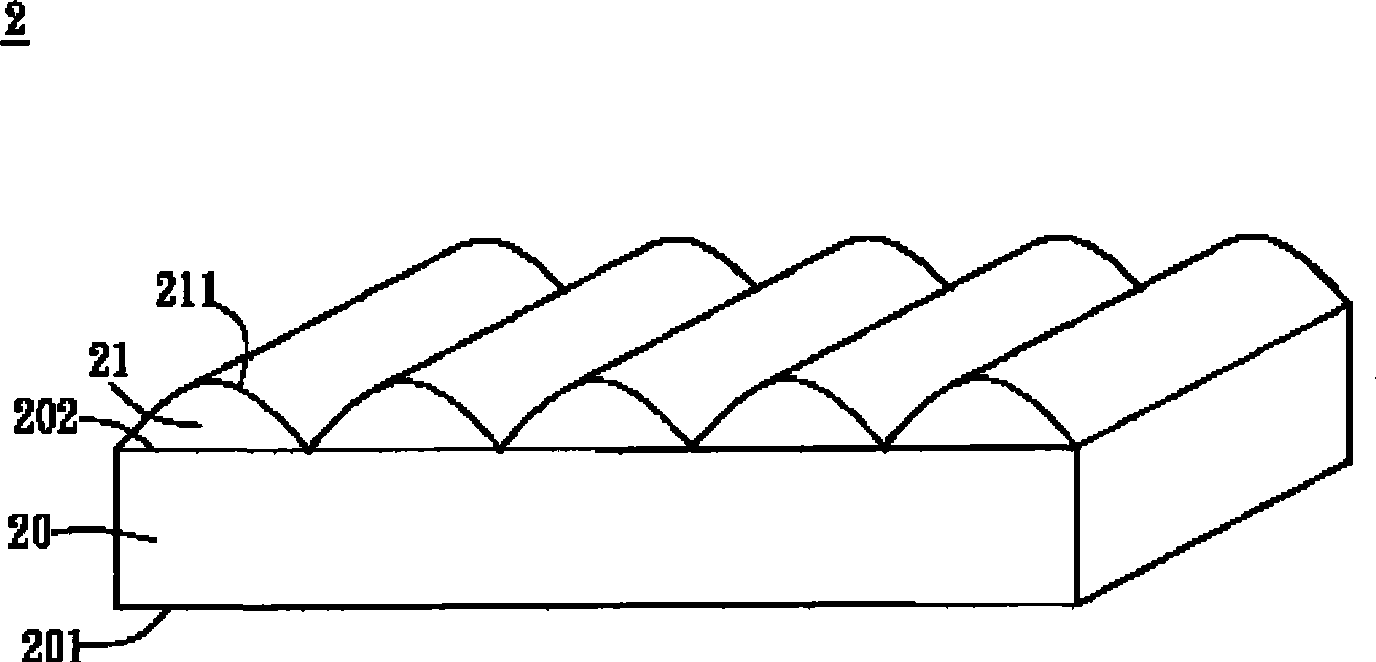

[0051] see image 3 As shown, an optical film 2 according to the first embodiment of the present invention includes a substrate 20 and a plurality of convex lens structures 21 . Wherein, the optical film 2 is an example of an optical film disposed in a backlight module of a liquid crystal display.

[0052] The substrate 20 has a first surface 201 and a second surface 202 , and the first surface 201 is opposite to the second surface 202 . Wherein, the material of the substrate 20 is transparent polyethylene terephthalate (PET) or polycarbonate.

[0053]The convex lens structures 21 are arranged in parallel and disposed on the second surface 202 of the substrate 20 . Each convex lens structure 21 has an arc surface 211, and the arc surface 211 conforms to a curved surface formula Ax 2 +By 2 +Cxy+Dx+Ey+F=0. It should be noted that in the surface formula, x and y are variables, and coefficients A, B, C, D, E, and F are constants, and the values of coefficient A and coeffici...

no. 2 example

[0059] see Figure 7 As shown, an optical film 3 according to the second embodiment of the present invention includes a substrate 30 , a plurality of convex lens structures 31 and at least one triangular prism structure 32 . Wherein, the first surface 301 and the second surface 302 of the substrate 30 are disposed opposite to each other, and the material of the substrate 30 is the same as that of the substrate 20 in the first embodiment, so details will not be repeated here. The convex lens structures 31 are arranged adjacent to the triangular prism structure 32 and are arranged on the second surface 302, and the height H3 of the triangular prism structure 32 is smaller than the height H1 of the convex lens structure 31, so as to prevent the apex angle of the triangular prism structure 32 from being damaged. . It should be noted that the triangular prism structure 32 is used to increase the light-gathering effect of the optical film 3 , and the optical film 3 can adjust the q...

no. 3 example

[0061] see Figure 8 As shown, an optical film 4 according to the third embodiment of the present invention includes a substrate 40 , a plurality of convex lens structures 41 and a diffusion material 43 . The first surface 401 and the second surface 402 of the substrate 40 are disposed opposite to each other, and the convex lens structures 41 are disposed on the second surface 402. The material of the substrate 40 is the same as that of the substrate 20 in the first embodiment, and details are not repeated here. The diffusion material 43 can be disposed on the substrate 40 and / or the lenticular structure 41 . In this embodiment, the diffusion material 43 is disposed in the substrate 40 and the convex lens structure 41 in a doping manner, for example. Wherein, the diffusion material 43 is diffusion particles of titanium dioxide or silicon dioxide, or multilayer diffusion particles with different refractive indices.

[0062] like Figure 9 shown, with Figure 8 The differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com