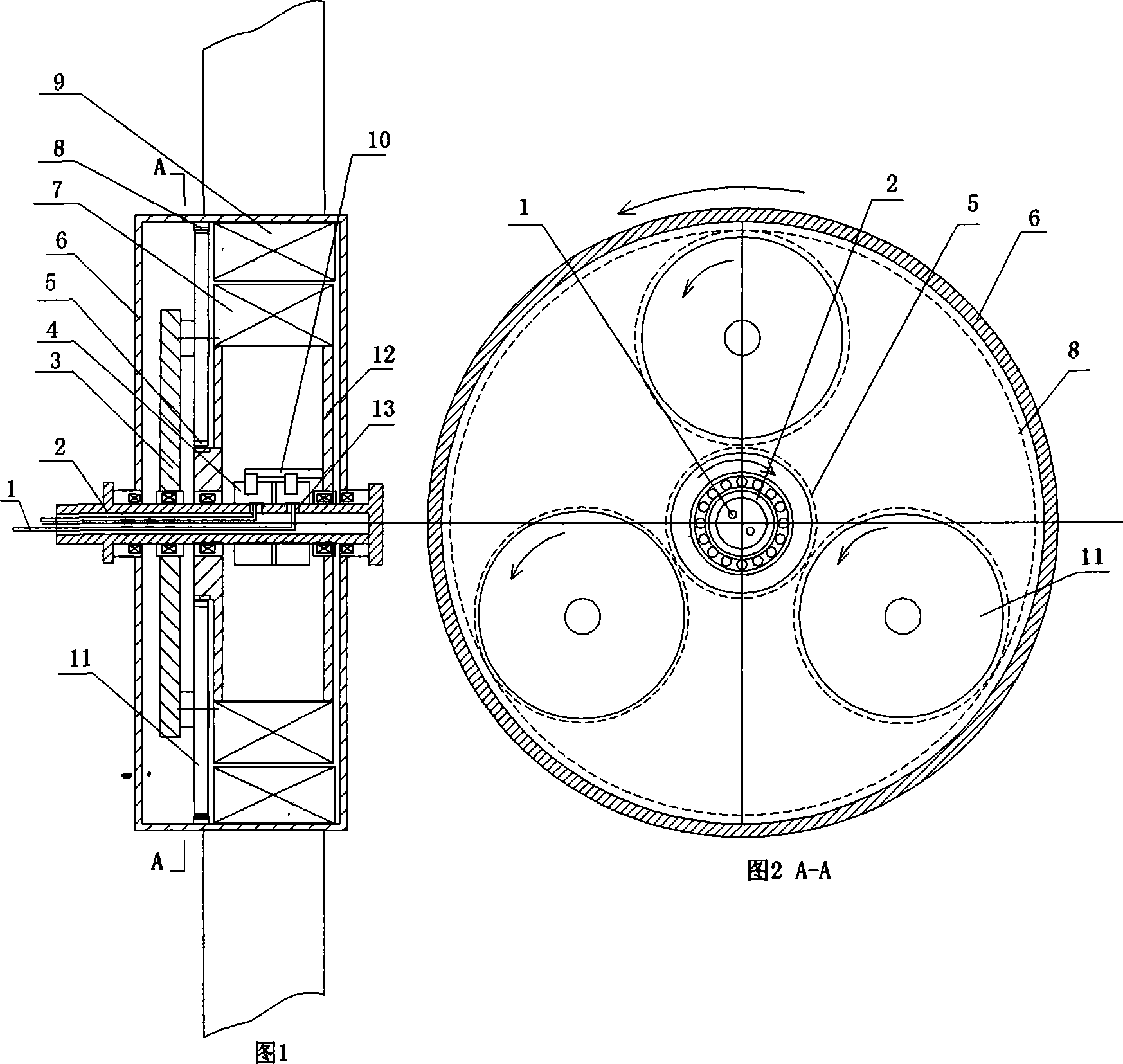

Double rotor planet differential electricity generator

A dual-rotor, generator technology, applied in electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of low wind speed wind energy waste, cost pollution, inability to meet the generator speed, etc., and achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] The intimate winding of the outer rotor can use permanent magnets or closed magnetic circuit windings, and the manufacturing process is all general-purpose motor manufacturing technology.

[0014] Generator of the present invention, its manufacturing technology is general motor processing technology, can be processed and manufactured as shown in the accompanying drawings of the description. This motor is mainly used in wind turbines or hydroelectric generators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com