C.I. pigment red 57:1 and its manufacturing method

A technology of pigment red and hydroxyl, which is applied in the field of C.I. Pigment Red 57:1 and its preparation, can solve the problems that cannot be easily removed, and achieve the effect of reducing usage and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] After dispersing 34.80 parts of 4-aminotoluene-3-sulfonic acid (purity 98.00%) in 50 parts of water, add 22.1 parts of 35% hydrochloric acid, and add 32.4 parts at once while adding ice and water to keep the temperature at 0°C of 40% sodium nitrite. 650 parts of a suspension containing a diazo component are obtained. Next, after dispersing 34.98 parts of 3-hydroxyl-2-naphthoic acid (purity 98.50%) in 400 parts of 50°C water, 69 parts of 25% caustic soda aqueous solution was added and dissolved, and thereafter, ice and water were added to obtain 980 Part 10 ℃ aqueous solution containing coupling agent components.

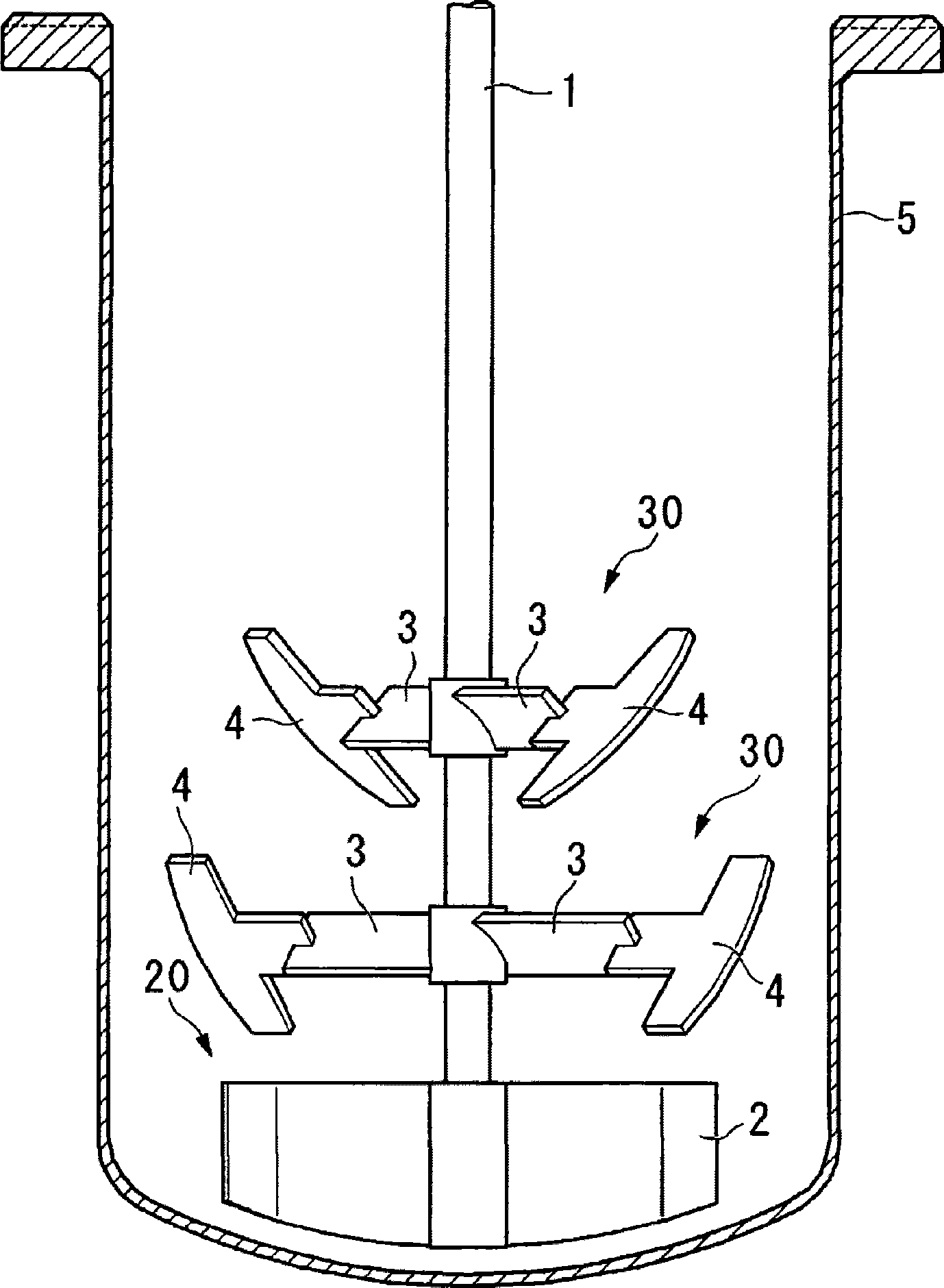

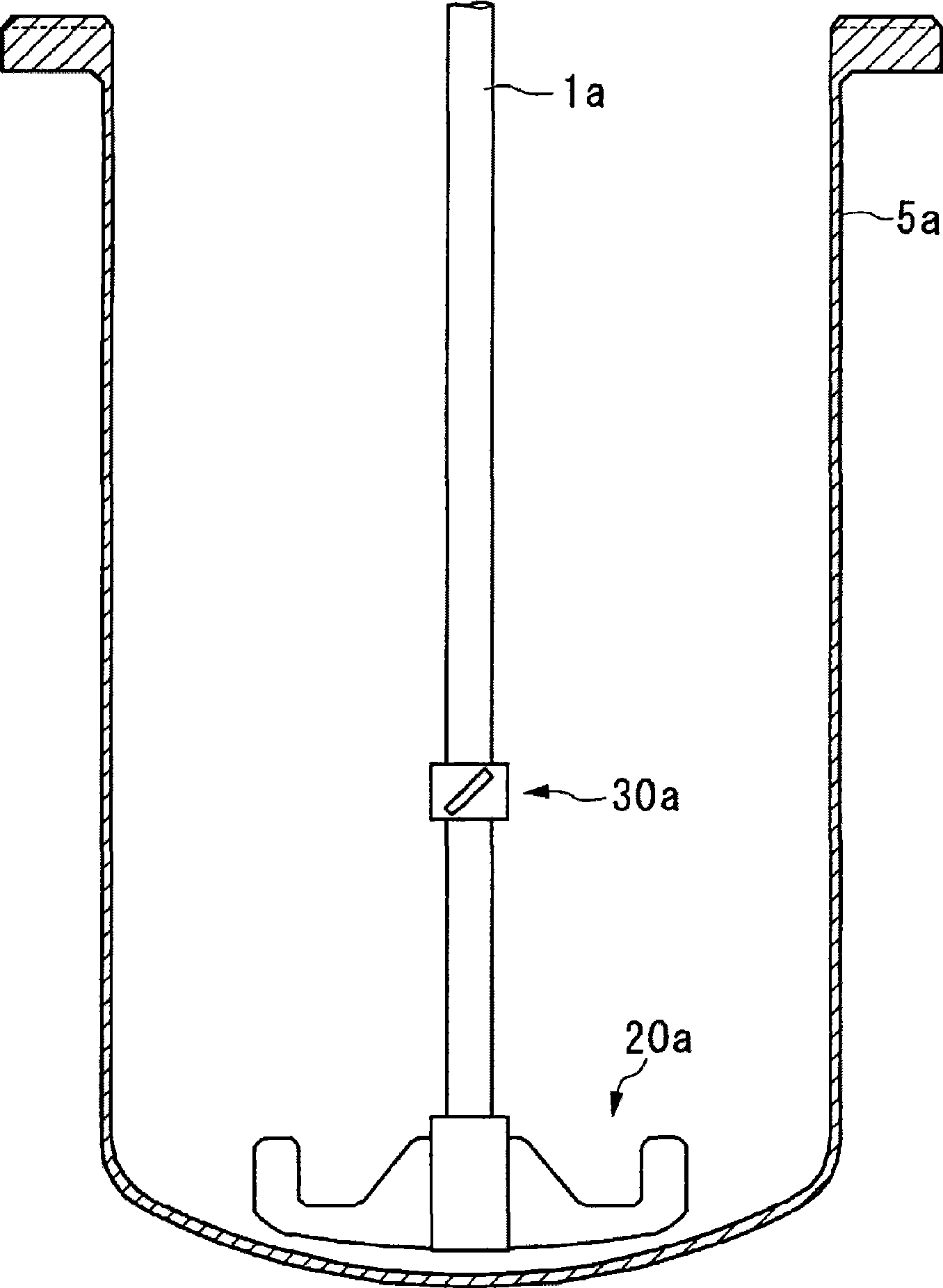

[0074] The aqueous solution containing this coupling agent composition is all added to the cylindrical stirring tank 5 of volume 2 liters, and the center of stirring tank 5 is assembled as figure 1 As shown, the rotating shaft 1 on which the stirring blade is installed is fixed to the power unit, and the stirring device is installed. Next, the rotating shaf...

Embodiment 2

[0082] Except for 4-aminotoluene-3-sulfonic acid:3-hydroxy-2-naphthoic acid (molar ratio)=1.000:1.002, the same procedure as in Example 1 was carried out to obtain 93 parts of dry pigment powder.

Embodiment 3

[0084] Except for 4-aminotoluene-3-sulfonic acid:3-hydroxy-2-naphthoic acid (molar ratio) = 1.000:1.003, the same procedure as in Example 1 was carried out to obtain 93 parts of dry pigment powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction rate constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com