C.I. pigment red 57:1 and manufacturing method thereof

A technology of pigment red and aminotoluene, which is applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems that cannot be easily removed, and achieve the effect of reducing usage and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] After dispersing 34.80 parts of 4-aminotoluene-3-sulfonic acid (purity 98.00%) in 50 parts of water, add 22.1 parts of 35% hydrochloric acid, and add 32.4 parts at once while adding ice and water to keep the temperature at 0°C of 40% sodium nitrite. 650 parts of a suspension containing a diazo component are obtained. Next, after dispersing 34.98 parts of 3-hydroxyl-2-naphthoic acid (purity 98.50%) in 400 parts of 50°C water, 69 parts of 25% caustic soda aqueous solution was added and dissolved, and thereafter, ice and water were added to obtain 980 Part 10 ℃ aqueous solution containing coupling agent components.

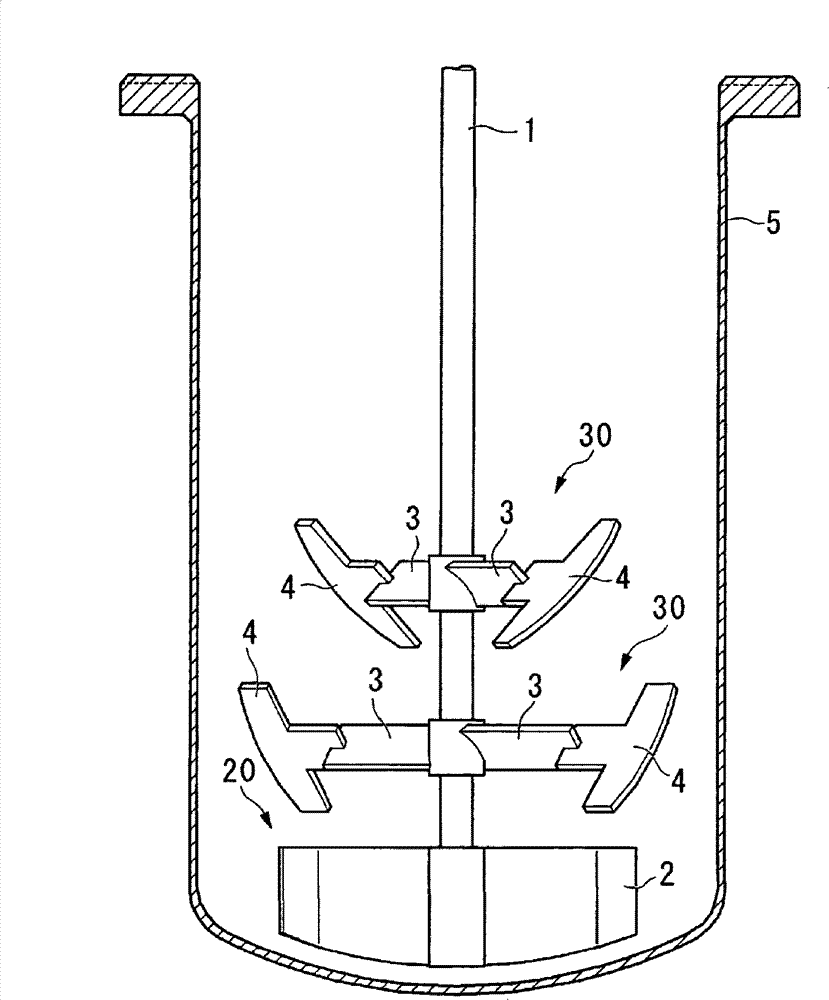

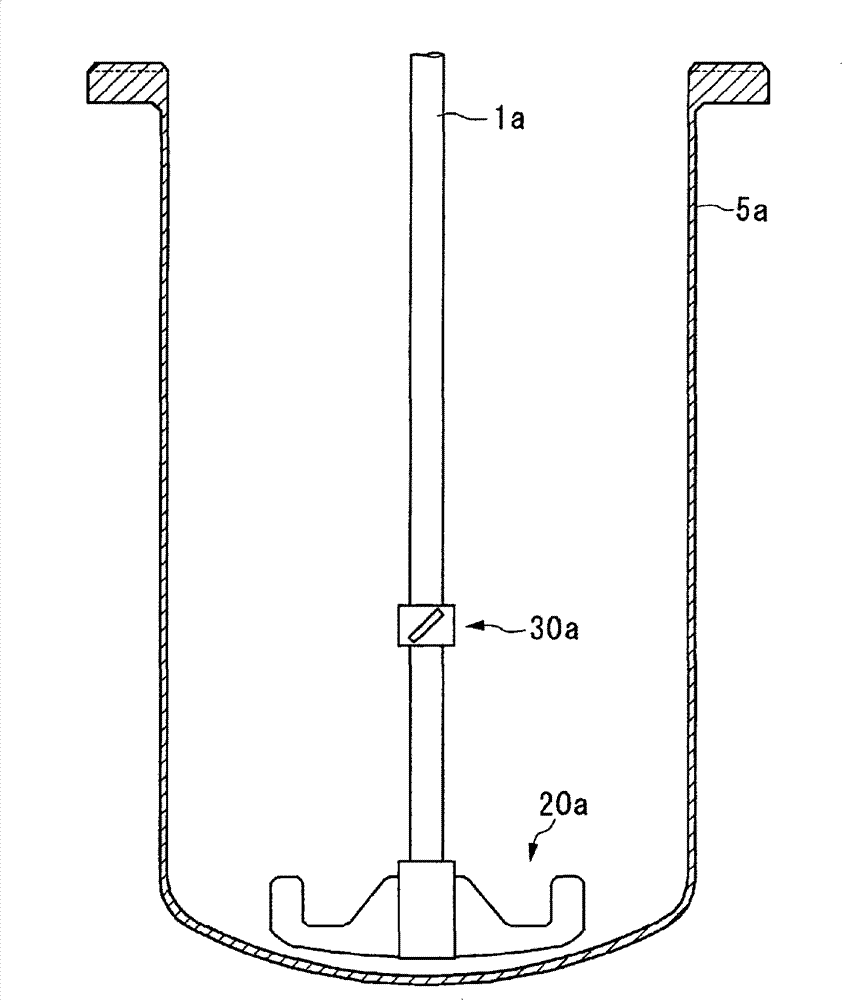

[0074] The aqueous solution containing this coupling agent composition is all added to the cylindrical stirring tank 5 of volume 2 liters, and the center of stirring tank 5 is assembled as figure 1 As shown, the rotating shaft 1 on which the stirring blade is installed is fixed to the power unit, and the stirring device is installed. Next, the rotating shaf...

Embodiment 2

[0082] Except for 4-aminotoluene-3-sulfonic acid:3-hydroxy-2-naphthoic acid (molar ratio) = 1.000:1.002, the same procedure as in Example 1 was carried out to obtain 93 parts of dry pigment powder.

Embodiment 3

[0084] Except for 4-aminotoluene-3-sulfonic acid:3-hydroxy-2-naphthoic acid (molar ratio) = 1.000:1.003, the same procedure as in Example 1 was carried out to obtain 93 parts of dry pigment powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction rate constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com