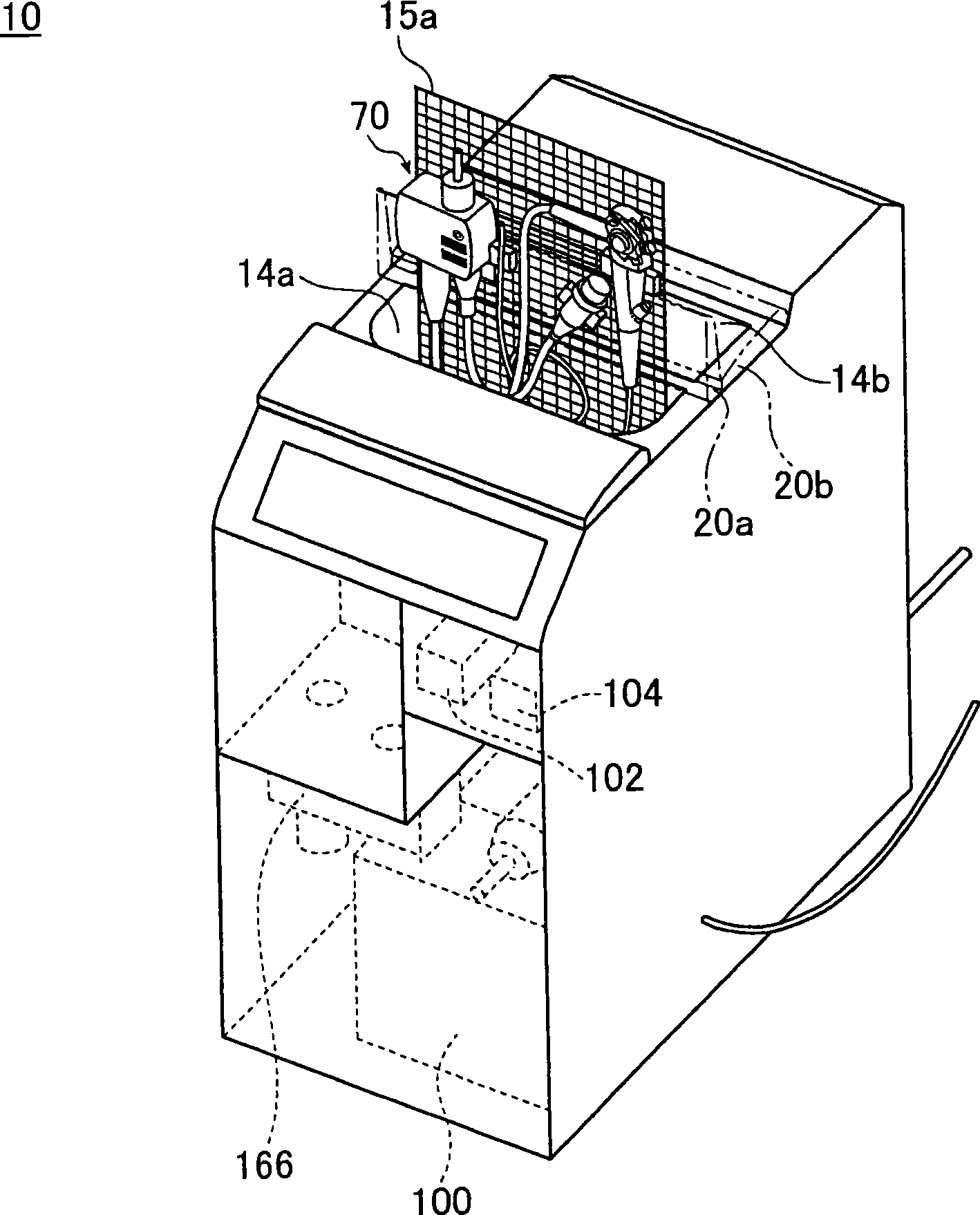

Endoscope reprocessor

A technology for endoscopes and washing machines, which is applied in disinfection, construction, water supply equipment, etc., can solve the problems of reduced disinfection capacity, residual treatment liquid, and longer cleaning and processing time of endoscopes, and achieve the goal of inhibiting deterioration and cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

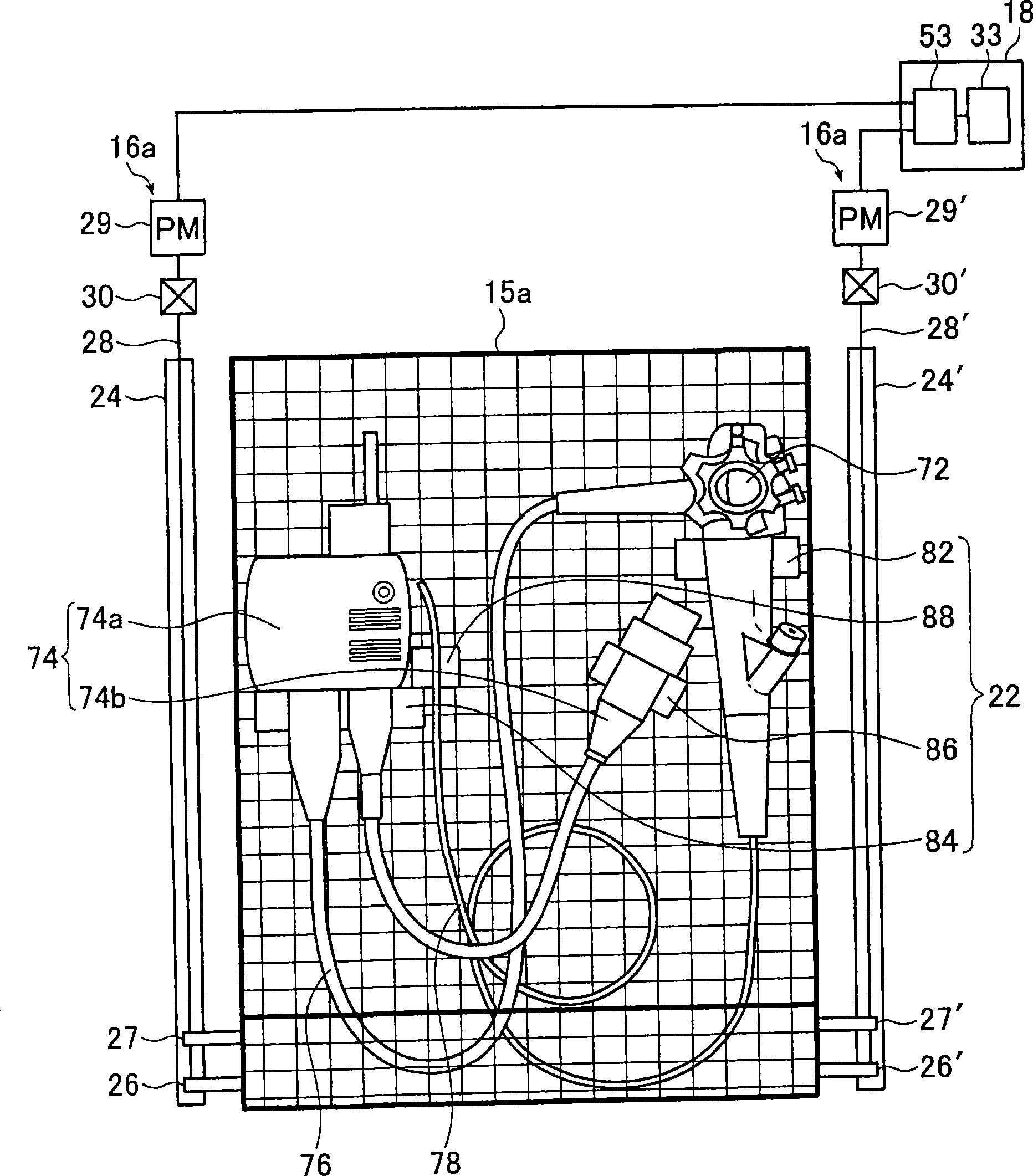

Method used

Image

Examples

Embodiment approach

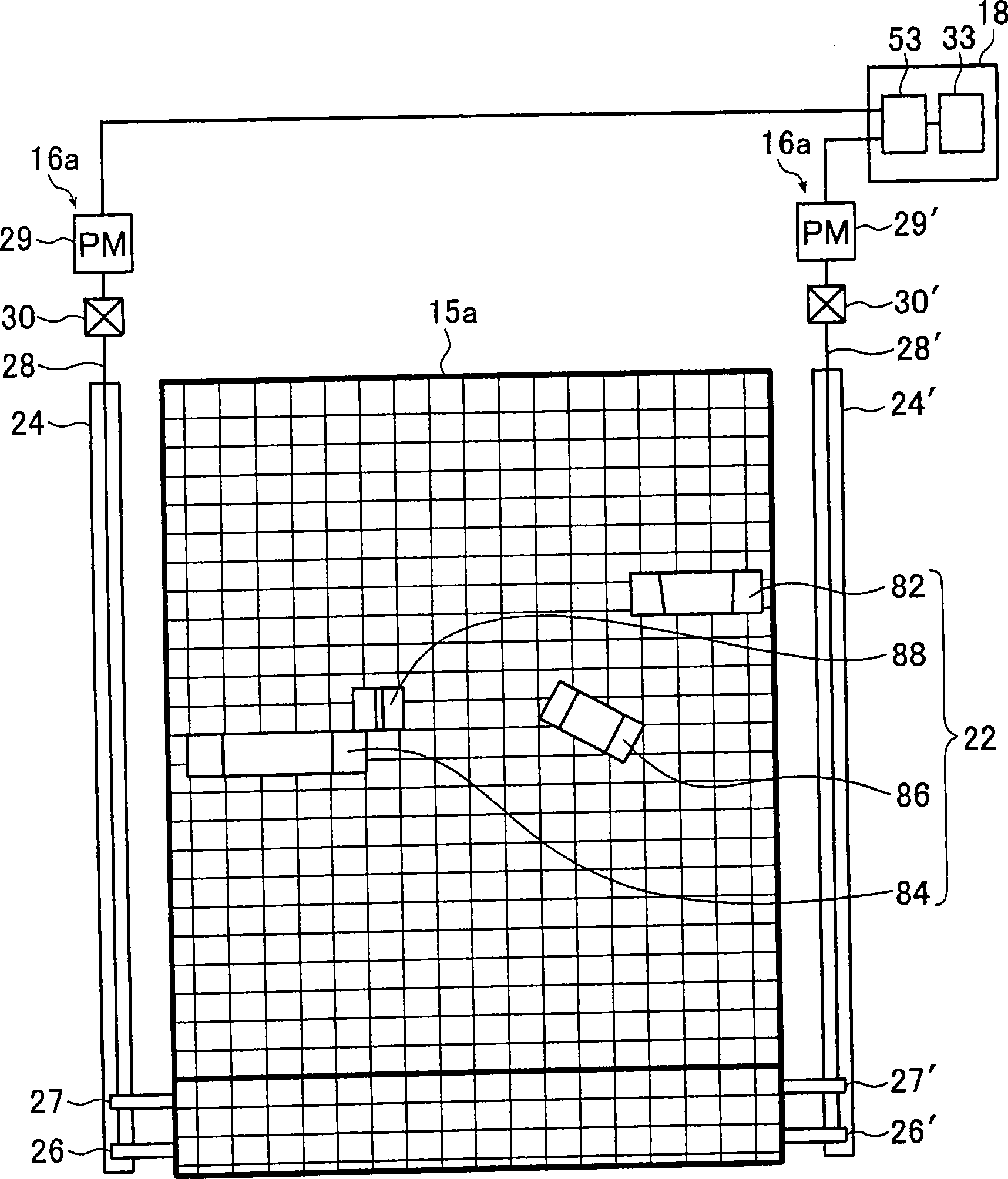

[0336] On the other hand, according to the second embodiment of the present invention, as described above, deterioration and reduction of the disinfectant solution can be suitably achieved.

[0337] Therefore, according to the washing machine 210 according to the second embodiment of the present invention, it is possible to stably perform proper cleaning of the endoscope 250, reduce the usage amount (filling amount) of the disinfectant solution and suppress the running cost, and shorten the length of the endoscope. The time for the cleaning process of the mirror 250 can be quickly and efficiently handled even when the endoscope 250 needs to be used repeatedly.

[0338] In the washer 210 of the second embodiment of the present invention, the shape of the cover body 220 of the cleaning tank 214 is not particularly limited, as long as it can be closed, it is preferable that the cleaning tank 214 (in the tank) can be closed in a substantially airtight (especially airtight) manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com