Fire-extinguishing agent nozzle of gas fire-extinguishing system

A fire-extinguishing system and technology of fire-extinguishing agent, applied in fire rescue and other directions, can solve the problems of small adjustment range of fire-extinguishing agent, affecting fire-extinguishing effect, poor atomization effect of fire-extinguishing agent, etc. Aesthetically pleasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

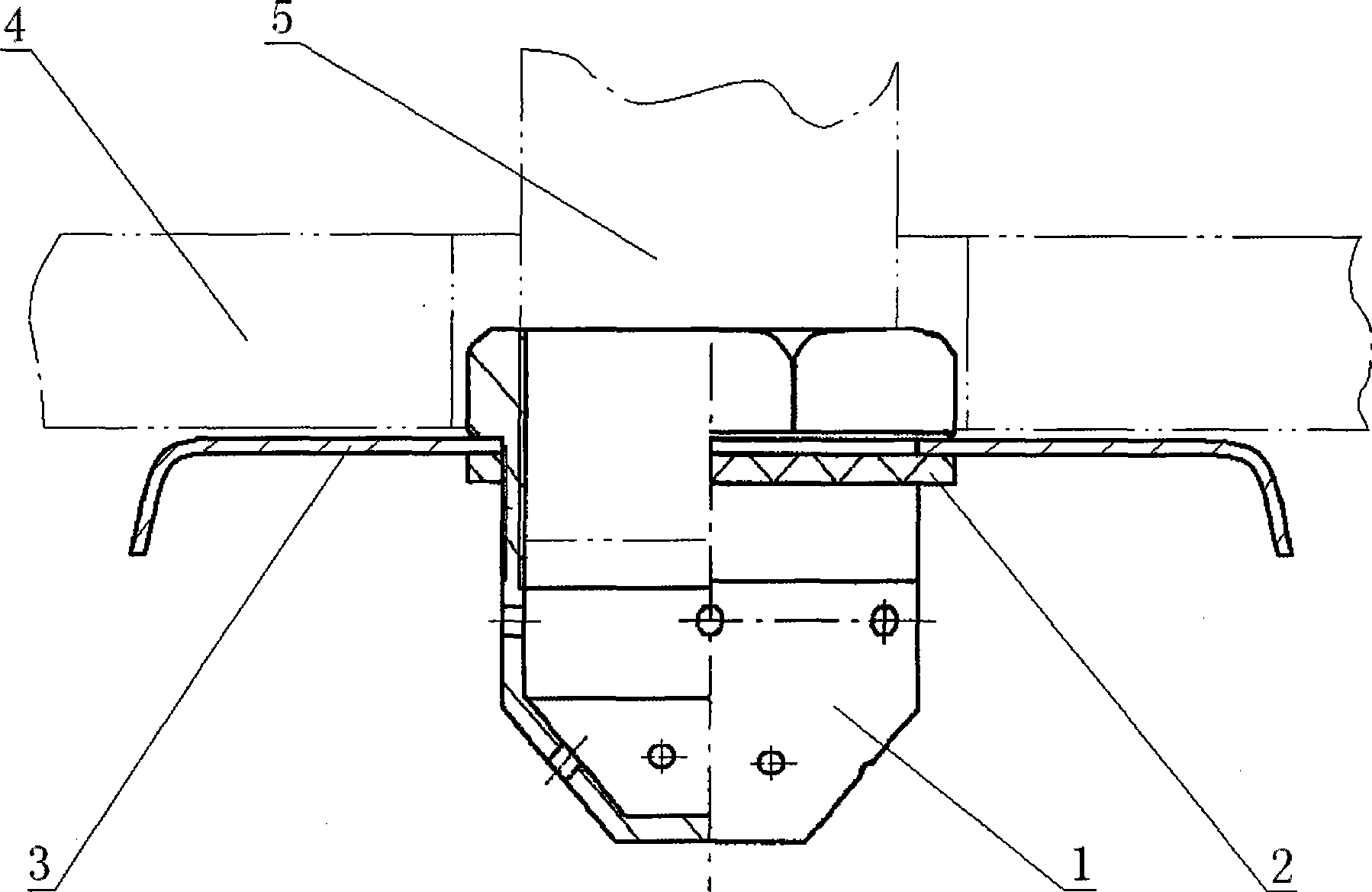

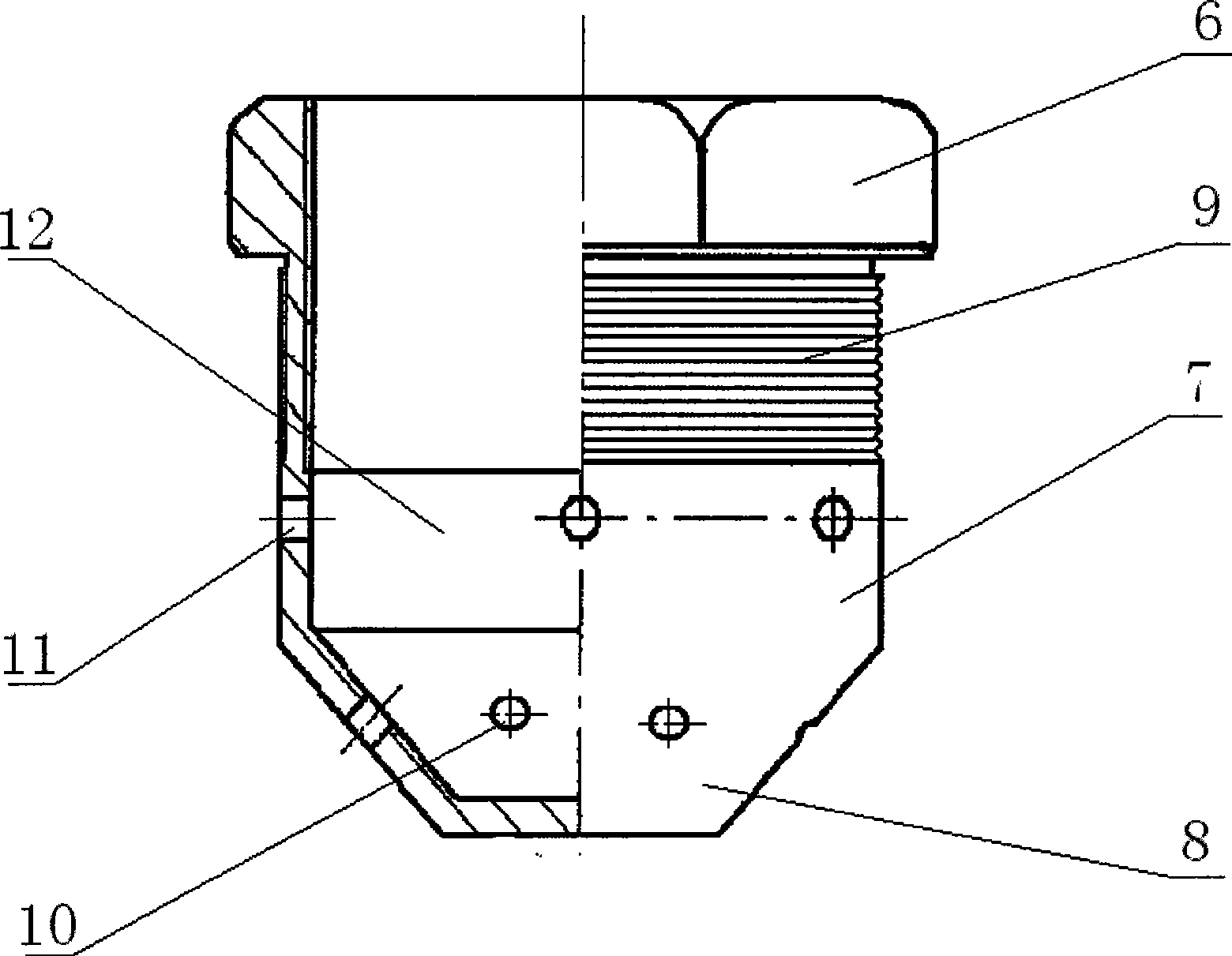

[0014] like figure 1 , figure 2 As shown, a fire extinguishing agent nozzle of a gas fire extinguishing system is composed of a nozzle body 1, a compression ring 2 and a protective atomization cover 3. The ring body and the curved body extending from the edge of the ring body are formed. The diameter of the protective atomization cover 3 can be 120-240 mm. The visual effect is better, and the atomization rate is the best, and the fire extinguishing effect is better.

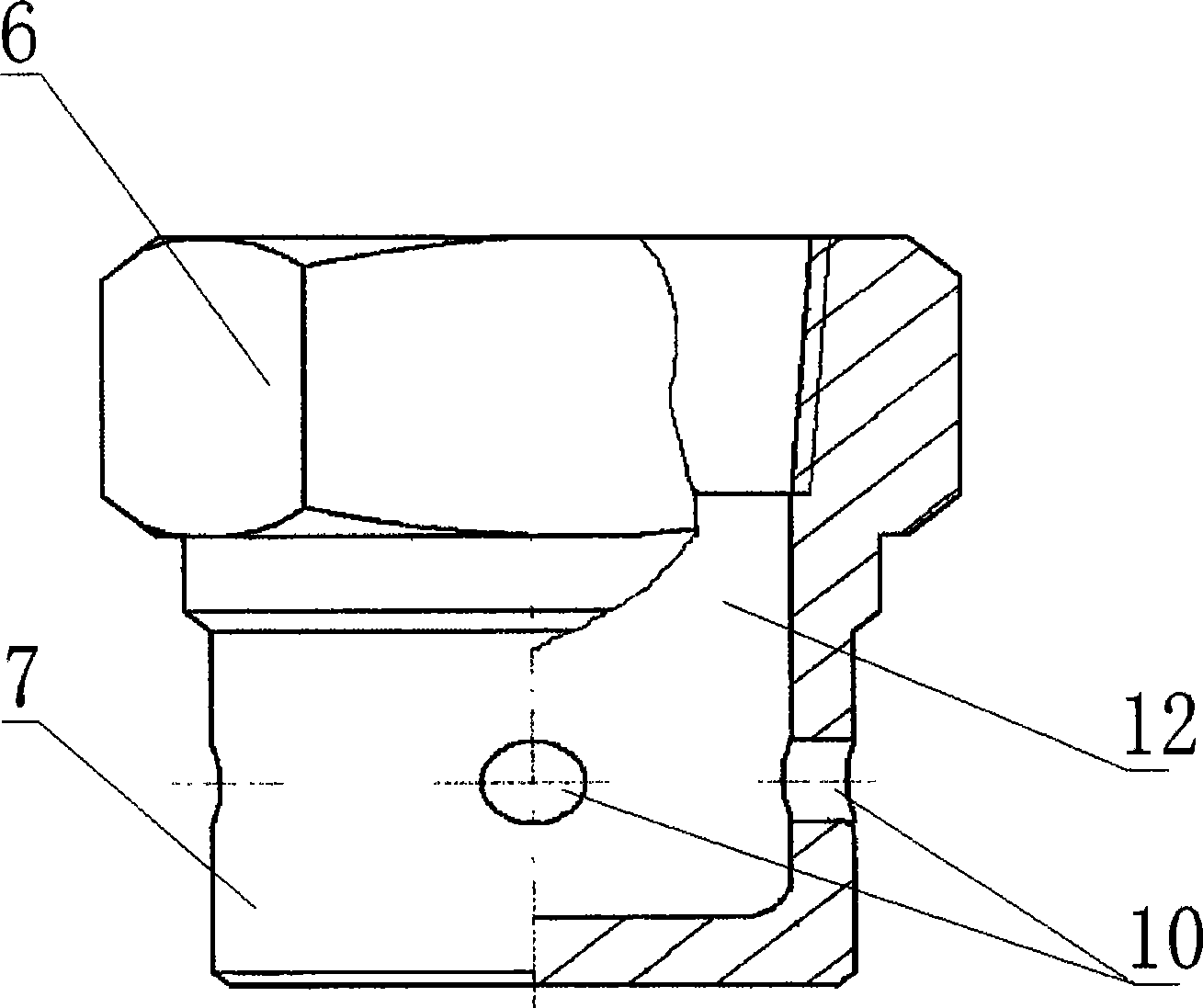

[0015] The nozzle body 1 is a metal processing part, and its outer surface is composed of the nut segment 6 with the largest diameter, the truncated cone 8 and the cylindrical segment 7 between the nut segment 6 and the truncated cone 8. The cylindrical segment 7 of the nozzle body 1 is close to the nut segment 6 has an external thread 9 that matches the compression ring 2. The nozzle body 1 is processed with a nozzle cavity 12, a nozzle hole 10, and an oblique nozzle hole 11. On the cylindrical section 7 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com